iTPC QA

This page and the child page will contain information on the QA of sectors, organized by sector number

SN1001 is the prototype SN00xx the production ones.

7/19/18 Added the daily test activity summary file. The daily updates are written by Qian, an has all entries in the file with the most recent first.

Latest version 8/26/2018

Hanseul made a nice webpage that shares all update on the iTPC testing.

https://docs.google.com/spreadsheets/d/11mFkoX1Mu64uL4oYq-vshhRE0bZa8CAqgsL1sToJ354/edit?usp=sharing

Summary of sector status 9/20/2018. A summary of problem sectors that should be considered as spare,

and not installed. Powerpoint File.

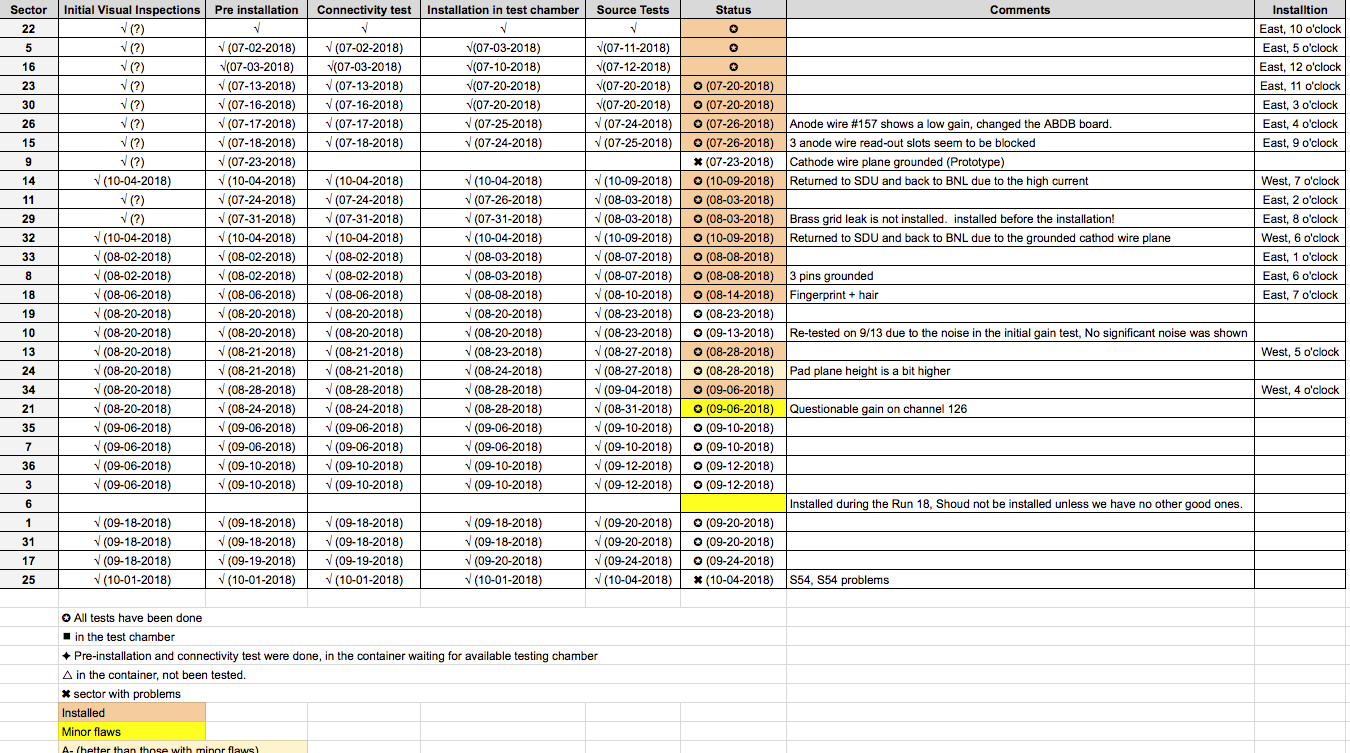

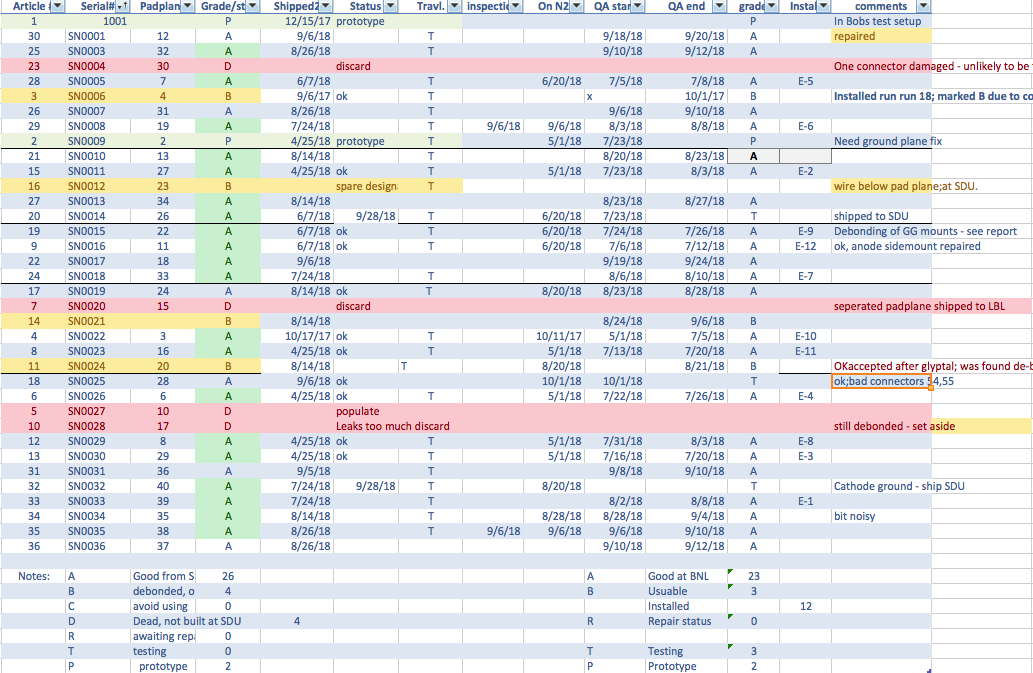

10/15/2018 screenshot of testing status at BNL

The material in the child pages are copies of the LBNL google pages, and additional analysis results that may have ben performed.

The LBL assembly instructions including check points is attached

The work at LBNL is completed as per 5/16/2018 and last sectors send to SDU

6/6/2018 : A pdf version of the final filled out smartsheet is saved here

6/6/2018: Jim and Howard have analyzed all the survey measurements. The spreadsheet that summarizes the results is attached here.

The Chinese travellers are updated to Quinghua's blog page

The travellers for testing at BNL are posted on https://www.star.bnl.gov/protected/heavy/tc88qy/iTPC/sector/

Travellers from the pre-installation check saved under each SNXXXX folder.

ITPC status 10/15/2018 . All sectors at BNL checked

Note:

The two failed sectors SN0027 and SN0020 had separated in wide corners. Look fo repairs at LBL.

SN0024 failed the very sensitive He-leak test at LBL vacuum was 10-4 above the limits. It can be shipped to SDU

and see if it passes the Ar sniffer test.

SN0028 had failed complete along long edge. May be difficult to repair should be set aside.

The article 31-36 are the additional strongbacks to be bonded. Padplanes on, sidemount done. Waiting for final machiung, CMM and cleaning.

It is believed that SN0012, SN0027 and SN0021 are repairable, planned to be done during feb-March until the strongbacks arrive from IMT

Washing procedure changes ; double check vacuum, refill with glyptal.

The padplane connectivity and checkout QA is in the summary attached, and provide a list of all pad planes (34) inspected and the summary from the

QA sheets used during inspection

Reports on various issue, found and resolved. This is work in progress

January 3, 2018

Report on shipping temperature for SN 1001

December 15, 2017

Report on 2 FEE slots in SN0025 blocked by epoxy

February 2, 2018

De-bonding of PCB to Al (GG wire) SN0015

March 21, 2018

Report on pad plane drilling survey at LBL for last 7

March 4, 2018

Report of shifted GG board on SN0012

April 3, 2018

Report of grounded pins on ABDB board on SN0008

Shipping of sectors

August 2018 SN0014,1715 and 10

The temperature from the USB file.

The box was opened on August 2.

The pdf of the graph is here.

September 18 SN0001, 17, 31

Temperature from sensor for shipment

Article 7 SN0020

Article 16 SN0012

This sector had a serious oversight during bonding resulting in a grounding wire caught below the pad plane.

As the wire is 600 microns think there is no way the flatness and bonding with expoxy which is only ~100 microns can be good.

Project have rejected this sector.

Article 17 SN0019

Article 18 SN0025

Article 19 SN0015

Article 20 SN0014

Article 20 SN0014

Docs from LBL assembly

Article 21 SN0010

Article 21 SN0010

Article 22 SN0017

SN0018 (Article 24)

SN0031 article 31

SN0031article 1 prototype SN1001

QA files for article 1.

article 10 SN0028

article 11 SN0024

article 12 SN0029

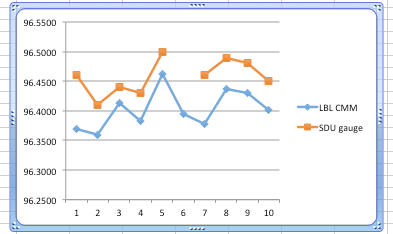

This sector was found at SDU to have the right GG side mount out of spec, just at limit where the

wire would touch the side mount surface

The figure shows the measurements from SDU and LBL CMM for righthand GG sidemount

The difference is understood due to way measurements are done 30-50 microns

A copy of the SDU traveler is at this location

article 13 SN0030

article 14 SN0021

article 15 SN0011

article 2 SN0009

QA infor from LBL and analysis

QA from SDU

article 3 SN0006

Traveller from SDU production link to Qinghua's blog

article 4 SN0022

LBL survey info

SDU scanned production traveller (upkoad 10/8/2017)

article 5 SN0027

The sector was rejected due to separated plane 8/16/1017 -- returned to LBL

The QA travellers from SDU

article 9 SN0016

QA from SDU

- Right side of anode wire mount apart from strongback about 5cm -- repaired at SDU

- two tapered pins extruded ~2mm beyond the side wire mount

- 5 pins of LOAB missing/broken repaired at SDU

- leakage found on 8 feed-through boards - re-epoxied

- Two fat wires used 75um BeCu wire used instead of 125 by mistake no effect from simulation by Irakli