- heppel's home page

- Posts

- 2021

- July (3)

- 2020

- February (1)

- 2019

- 2018

- 2017

- 2016

- December (2)

- November (2)

- October (3)

- September (2)

- August (1)

- July (3)

- June (5)

- May (8)

- April (4)

- March (1)

- February (2)

- January (2)

- 2015

- December (1)

- November (4)

- October (8)

- September (4)

- August (3)

- July (2)

- June (7)

- May (8)

- April (5)

- March (13)

- February (5)

- January (2)

- 2014

- December (1)

- November (2)

- September (1)

- June (3)

- May (2)

- April (1)

- March (3)

- February (2)

- January (1)

- 2013

- 2012

- 2011

- December (2)

- November (1)

- September (2)

- August (3)

- July (2)

- June (6)

- May (2)

- April (2)

- March (3)

- February (3)

- January (3)

- 2010

- December (1)

- November (2)

- September (2)

- August (1)

- July (4)

- June (3)

- May (2)

- April (1)

- March (1)

- February (2)

- January (1)

- 2009

- 2008

- My blog

- Post new blog entry

- All blogs

LargeCellCapPhotos

Here is the tube and base from with the cookie inserted in the front.

Figure 1

Here is the base rear insert with allen wrench showing how we lock down the components.

Figure 2:

The back retainer extends several mm beyond end of the magnetic shield.

Total length is shown

Figure 3:

The plug inserts in the end retairer.

Figure 4: (note that the wire holes are not proposed locations but are to show the range of possible locations)

Holes will be drilled through the top or sides of the plug. The plug shown will be machined so to eliminate the outside ridge that stops insertion by the last 1/4 in of the plug. Still the plug will extend outside nearly 1/4 in.

In figure 4 and 5, the grey hv wire is passing through the corner of the cap at about 45 degrees. This is one possible solution. Also shown is the black signal wire

which passes throug the top of the plug again at an angle of about 45 degrees.

We assume that the wires will enter the plug at opposite azimuthal locations either through the top or through the corner.

The retainer insert shown in Figures 2 and 3 will extend past the end of the shield by about .5 cm. A tapped hole in the extended part of the insert will allow

a allen screw to secure the plug. ( it is already quite tight without the screw).

Figure 5:

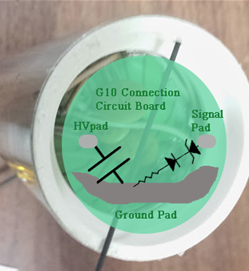

The current plan is to insert a simple round circuit board into Fig. 2. Radius of board will be the same as the plug insert of Figure 4 and 5. The circuit board will have

solder pads on the base side for connection to the high voltage and signal line. On the opposite side, the circuit board will have corresponding solder pads for the external HV and signal connections as well as high voltage capacitor and the protection components on signal (2 resistors + 2 diodes).

- heppel's blog

- Login or register to post comments