2009

Year 2009 posts

01 Jan

January 2009 posts

2009.01.08 Away side jet pt vs. photon pt

Ilya Selyuzhenkov January 08, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

Comments

(concentrated on pre-shower1>0 case

which has better statistics for QCD Monte-Carlo):

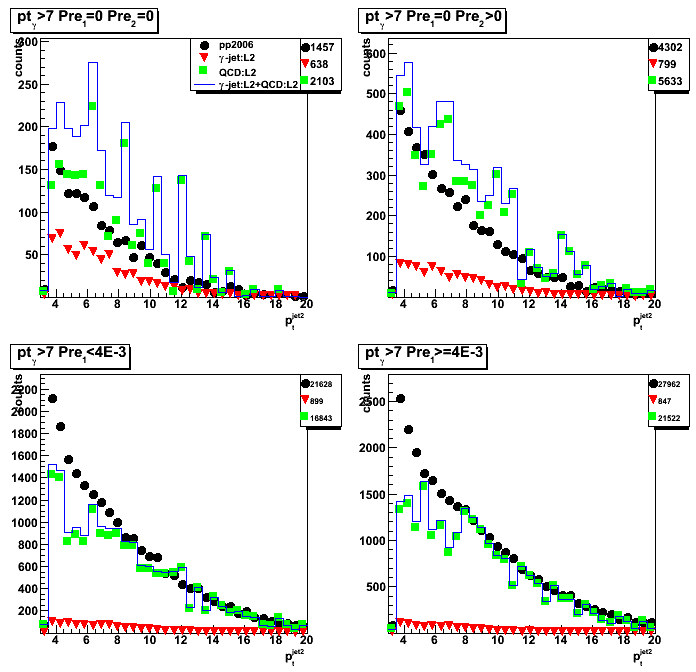

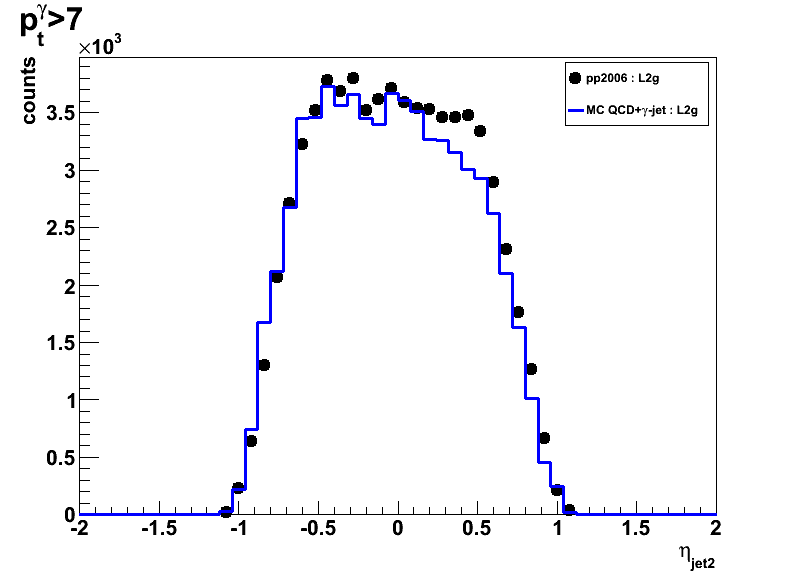

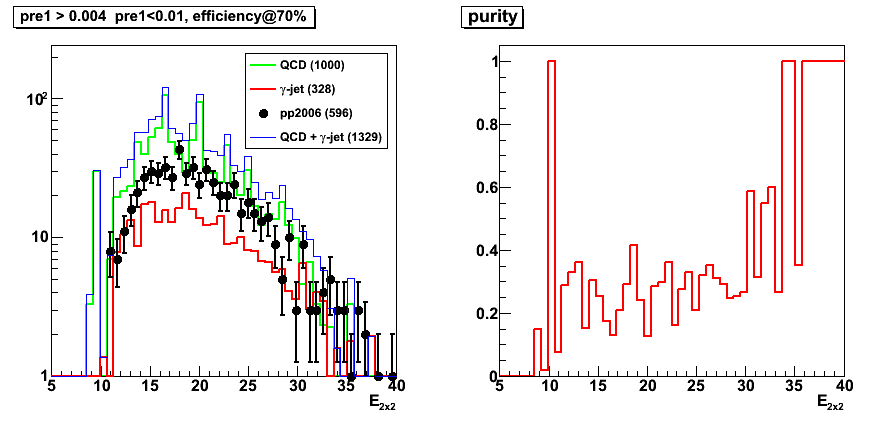

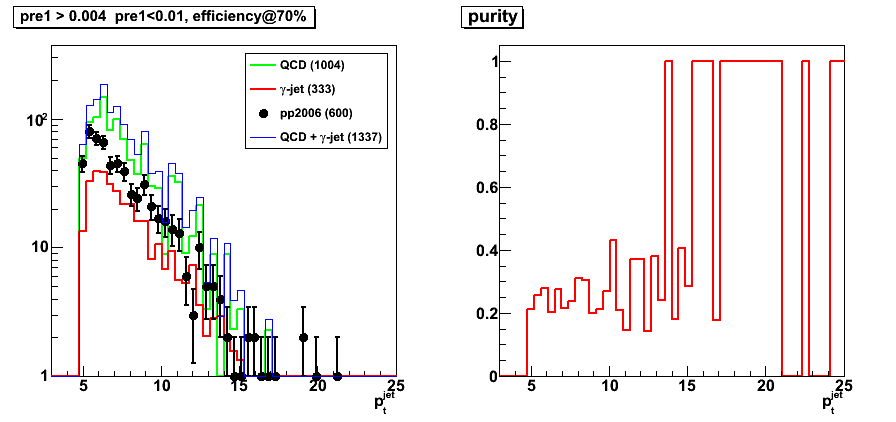

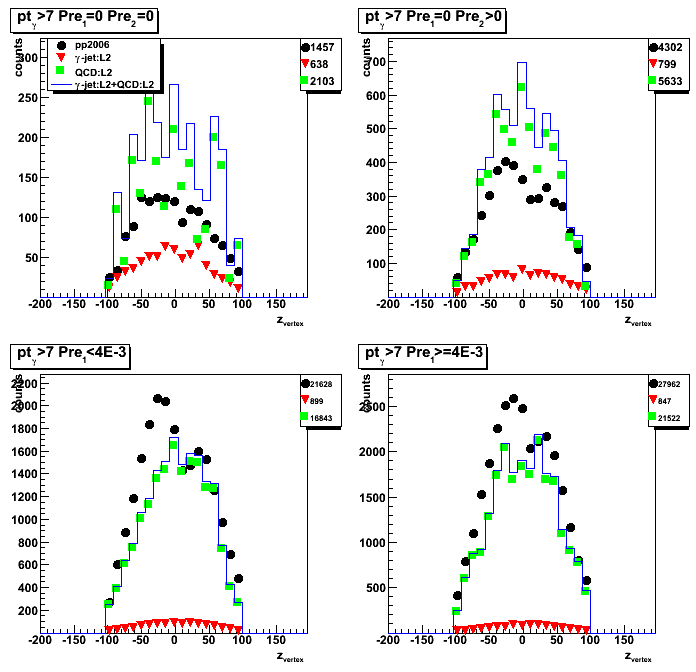

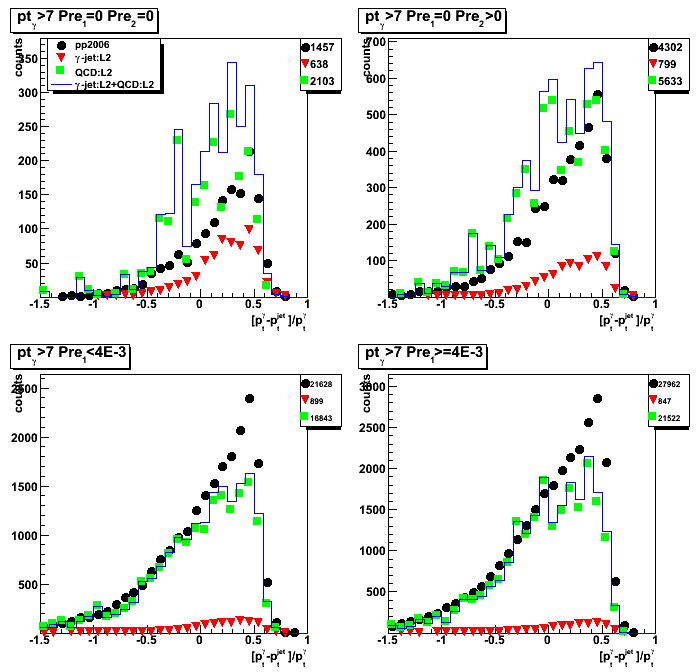

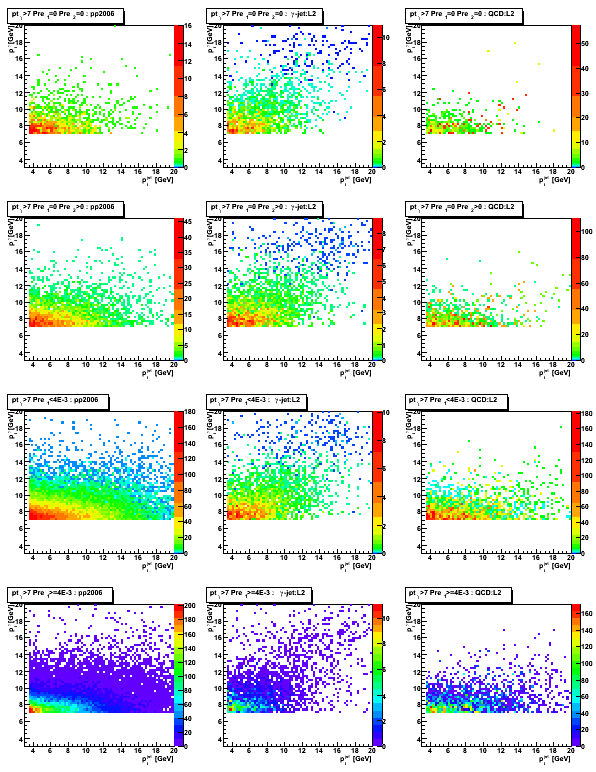

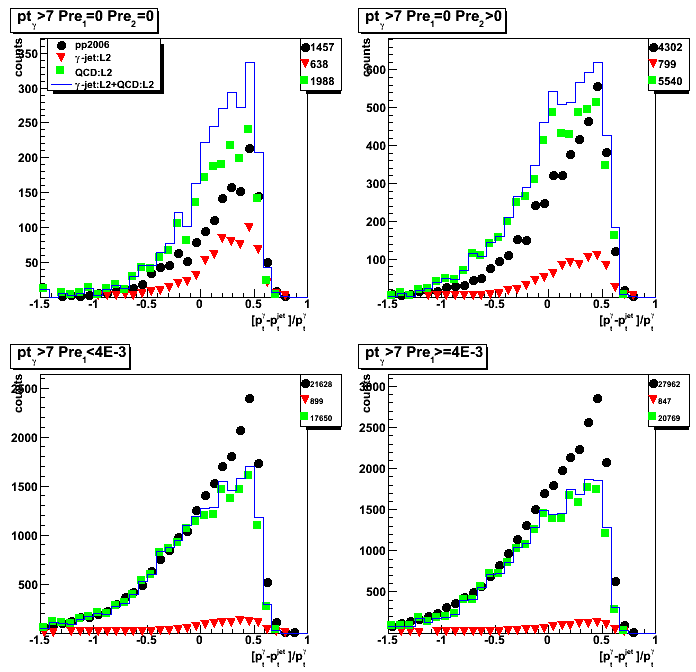

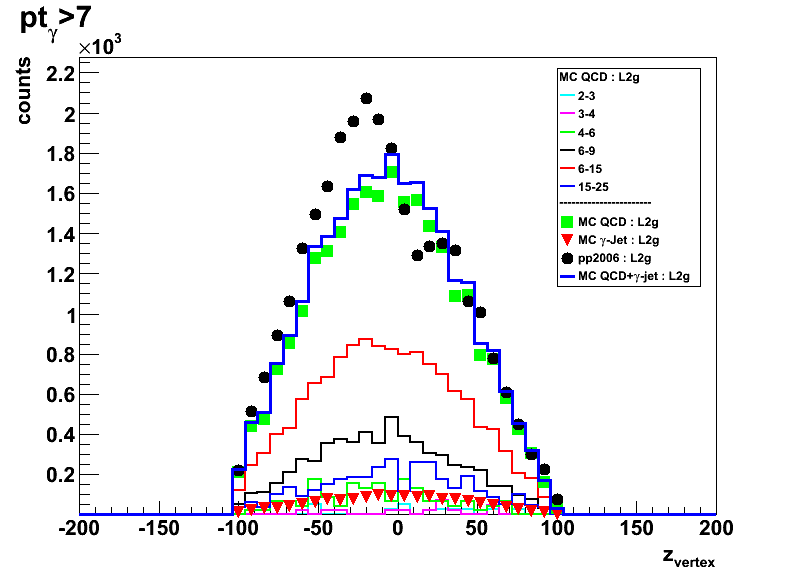

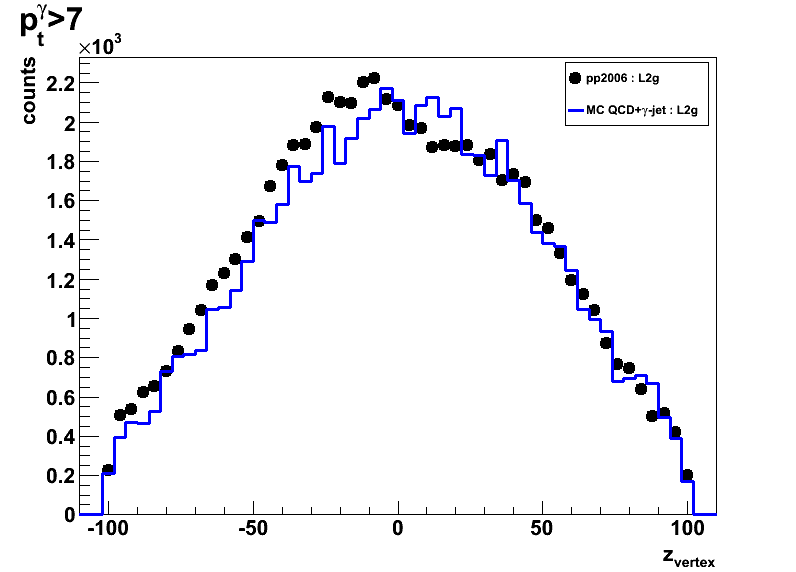

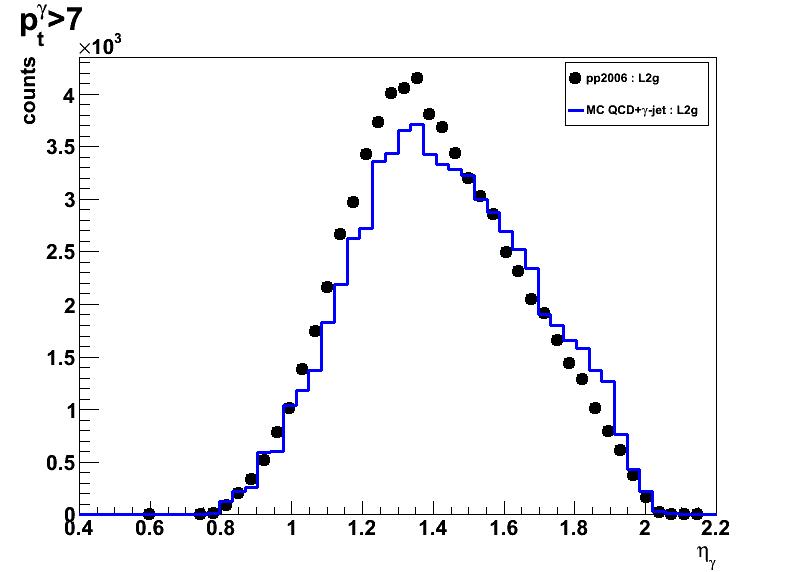

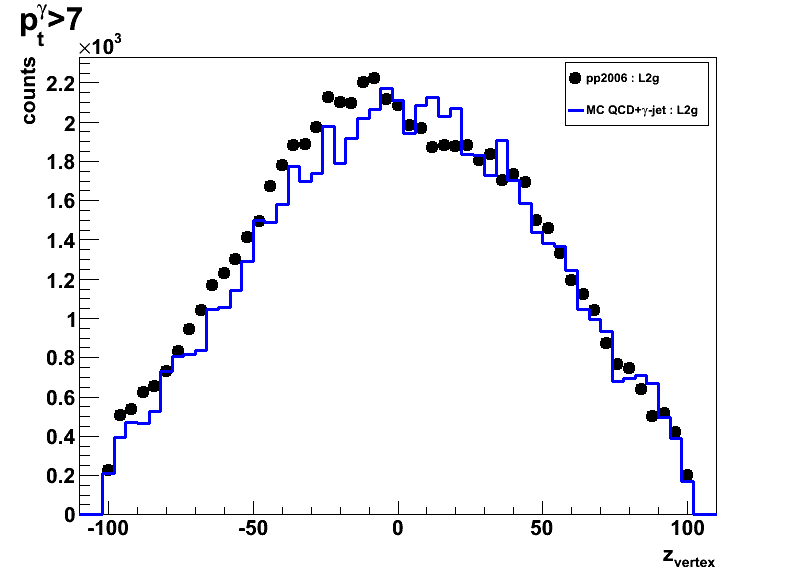

- Fig.1, lower plots

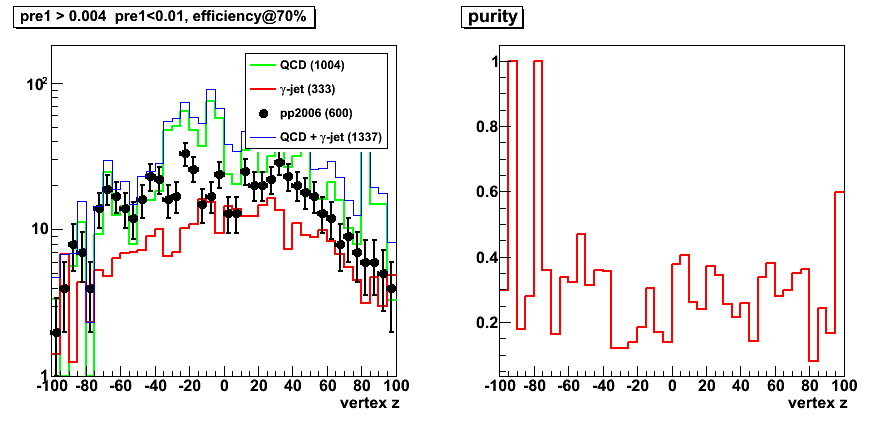

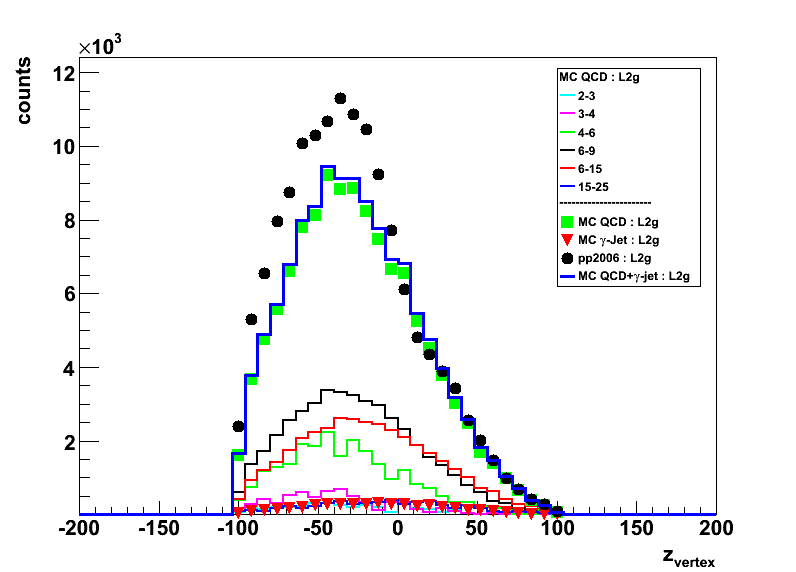

Vertex z distributions from QCD MC and pp2006 data are different in the negative region - Fig.2, lower plots

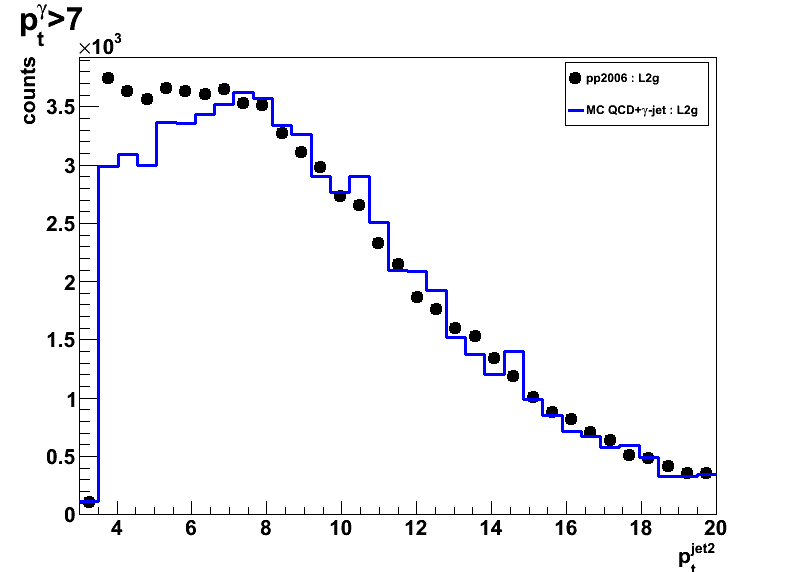

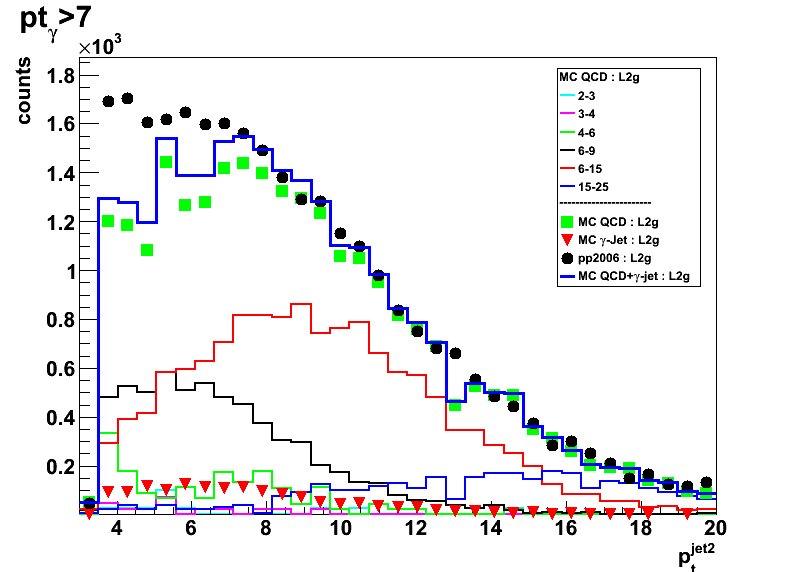

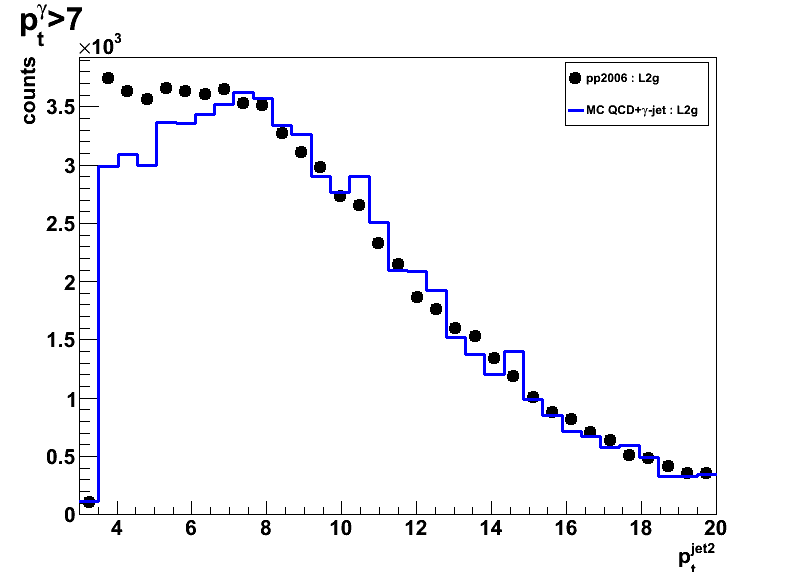

For the away side jet pt < 8GeV region

QCD Monte-Carlo underestimates the data. - Fig.4, lower plots

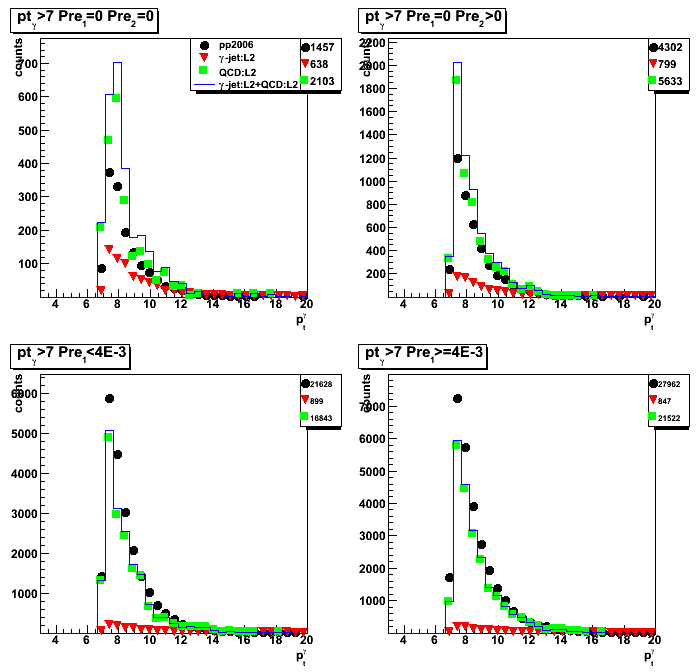

gamma-jet pt asymmetry plot shows

that in QCD MC photon and jet pt's are better correlated than in the data - Fig.5, lower plots

Most of the differences between QCD MC and pp2006 data for pre-shower1>0 case

are probably from the lower gamma and jet pt region

Figures

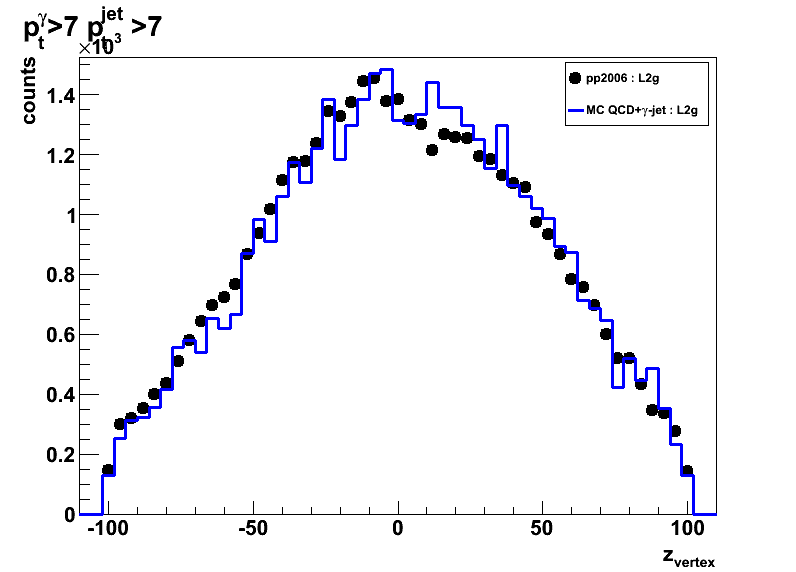

Figure 1: Vertex z distribution

Figure 4: gamma-jet pt asymmetry: (pt_gamma - pt_jet)/pt_gamma

Figure 5: gamma pt vs. away side jet pt

1st column: triggered pp2006 data

2nd column: gamma-jet MC (l2gamma trigger on)

3rd column: QCD background MC (l2gamma trigger on)

2009.01.20 Away side jet pt vs. photon pt: more stats for QCD pt_parton 9-15GeV

Ilya Selyuzhenkov January 20, 2009

Note:

this is an update with 10x more statitstics for QCD 9-15GeV parton pt bin.

See this post for old results.

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

Comments

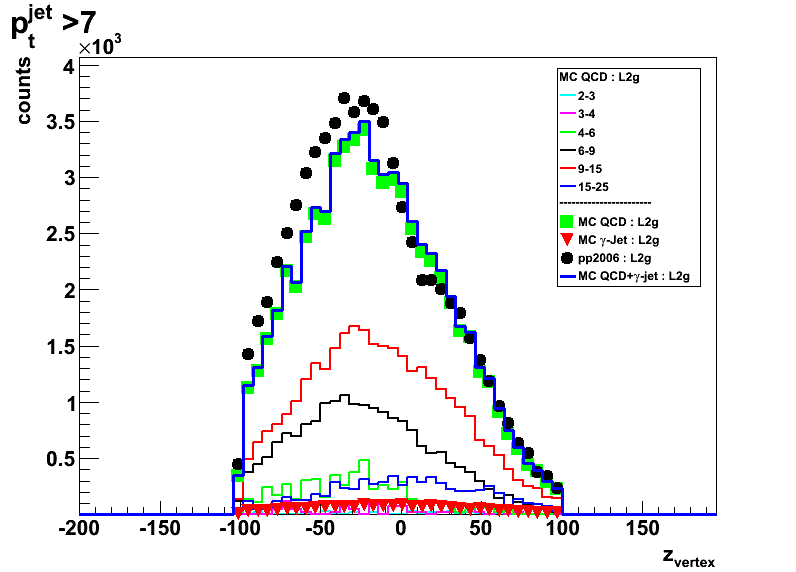

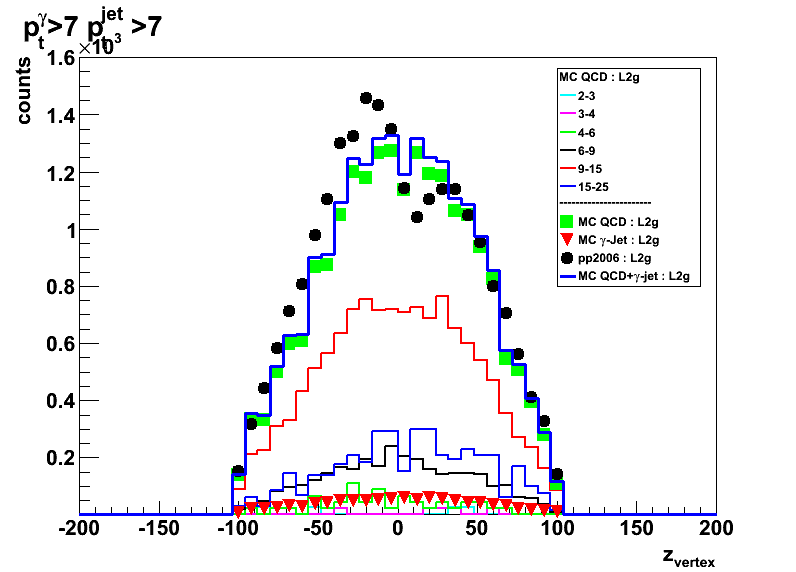

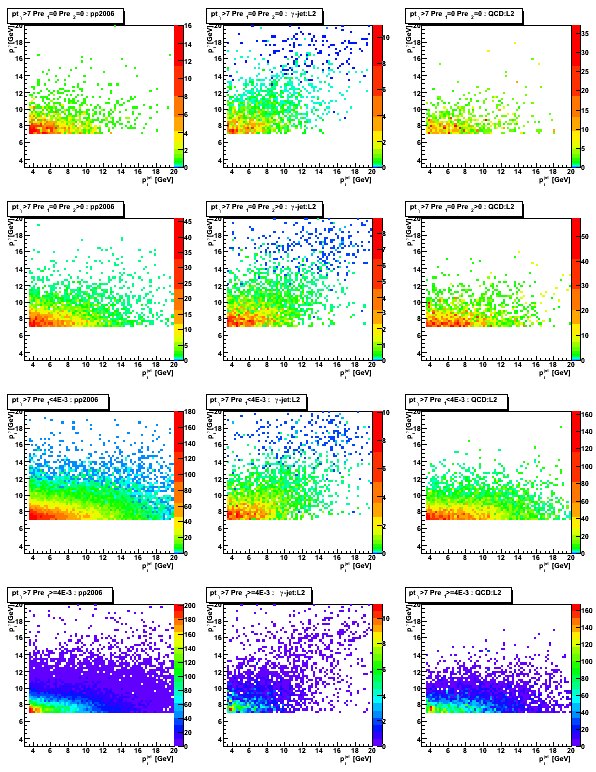

- Vertex z distributions from QCD MC and pp2006 data

are different in the negative region (see Fig.1) - pp2006 data to Monte-Carlo ratio

does not depends on reconstructed photon pt,

but it has some vertex z dependence

(see data to MC ratio in Fig.6 for pre-shower1 > 4MeV case)

Figures

Figure 1: Vertex z distribution

Figure 4: gamma-jet pt asymmetry: (pt_gamma - pt_jet)/pt_gamma

Figure 5: gamma pt vs. away side jet pt

1st column: triggered pp2006 data

2nd column: gamma-jet MC (l2gamma trigger on)

3rd column: QCD background MC (l2gamma trigger on)

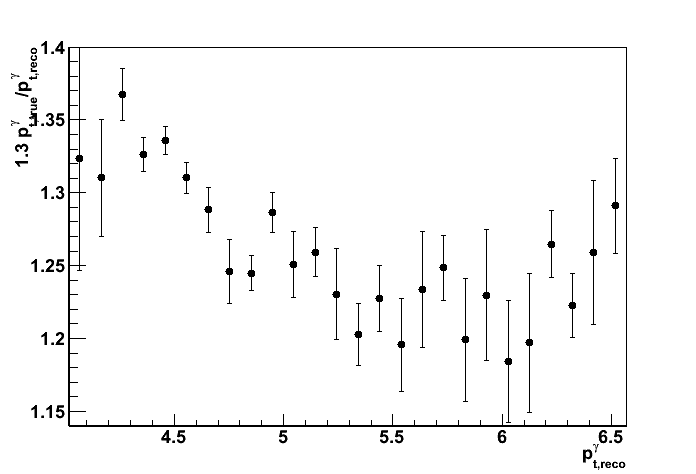

Data to Monte_Carlo normalization

Figure 6: pp2006 data to Monte -Carlo sum [QCD + gamma-jet] ratio

for pre-shower1>4MeV (most of statistics)

Left: data to MC ratio vs. reconstructed gamma pt.

Solid line shows constant line fit (p0 ~ 1.3)

Right: data to MC ratio vs. reconstructed vertex position

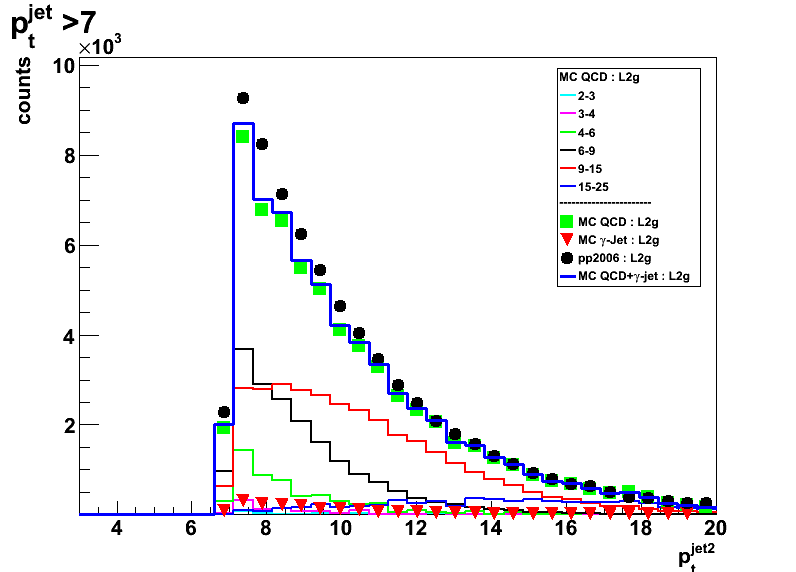

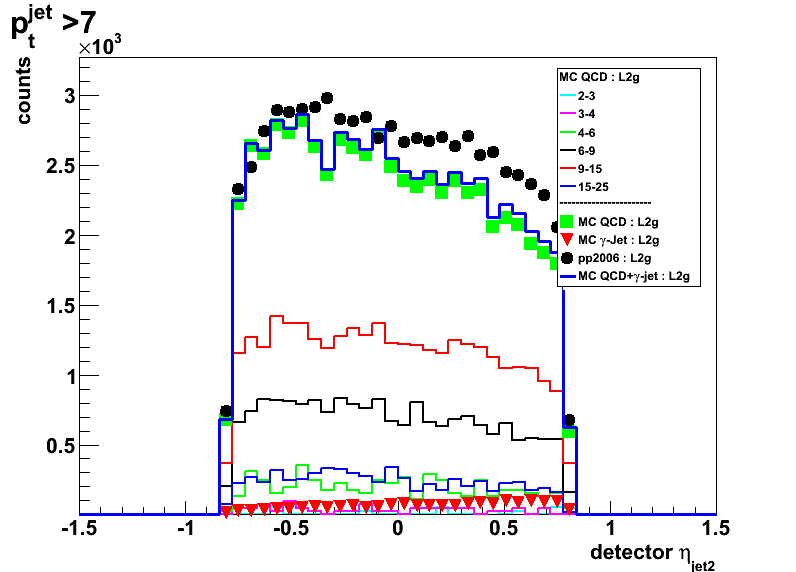

2009.01.27 gamma and jet pt plots with detector |eta|_jet < 0.8, pt_jet > 7

Ilya Selyuzhenkov January 27, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- jet pt > 7GeV

- Gamma pt > 7GeV or no pt cuts

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

Figures

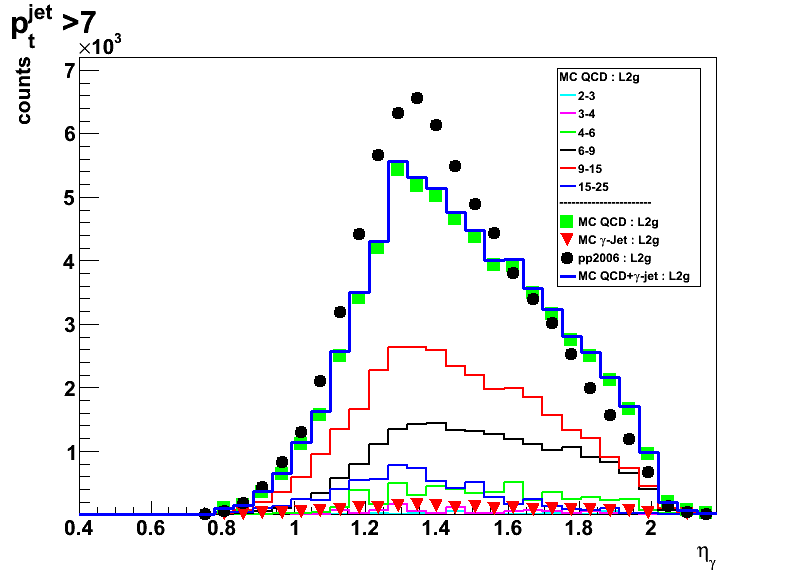

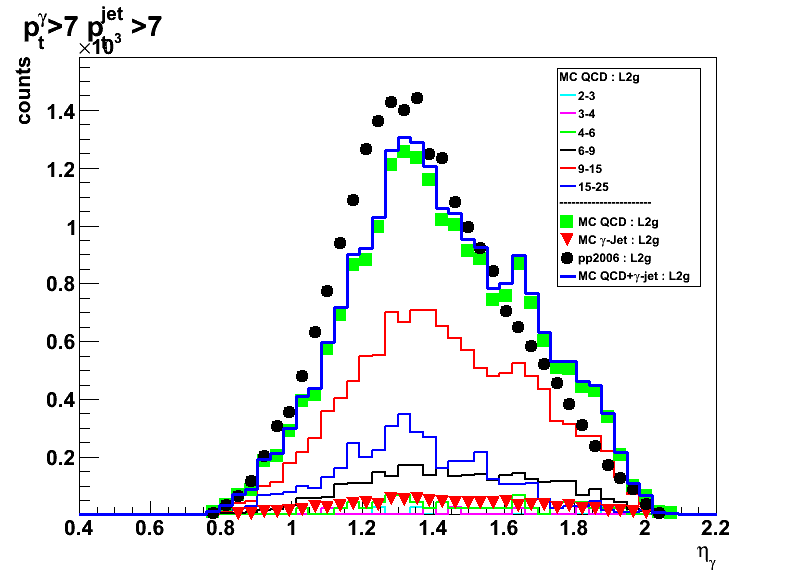

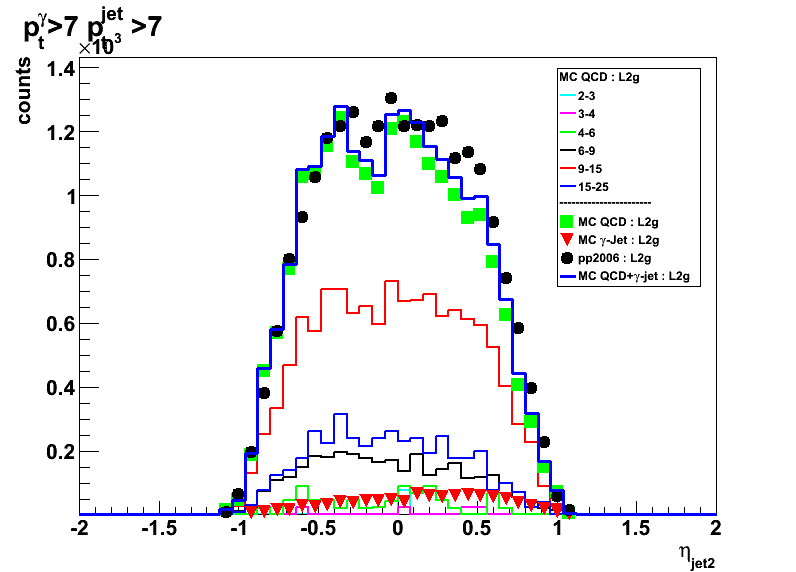

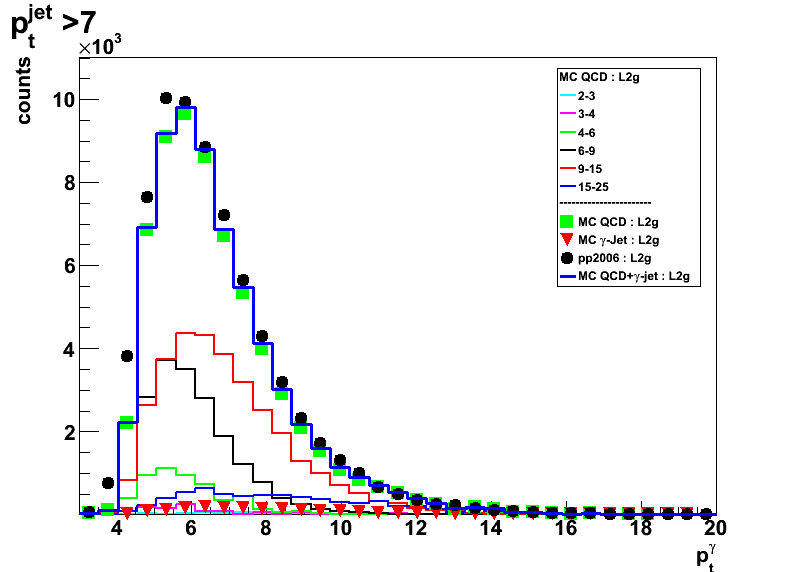

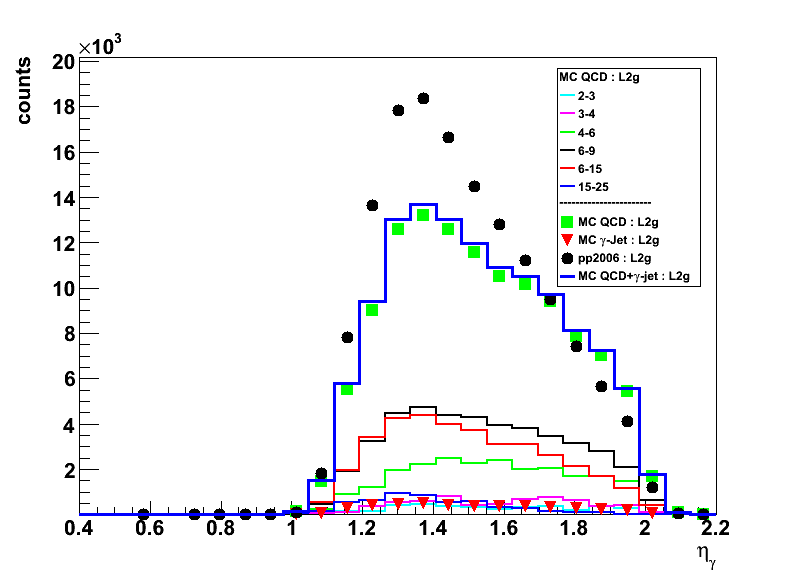

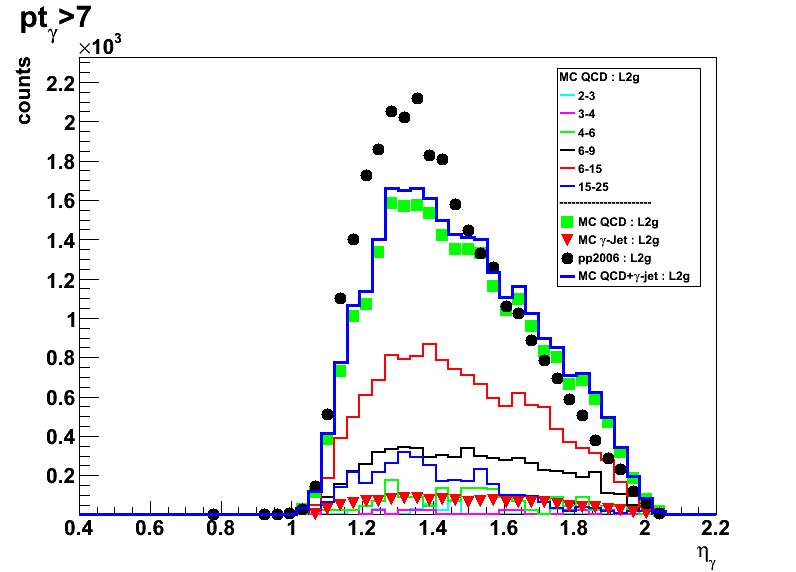

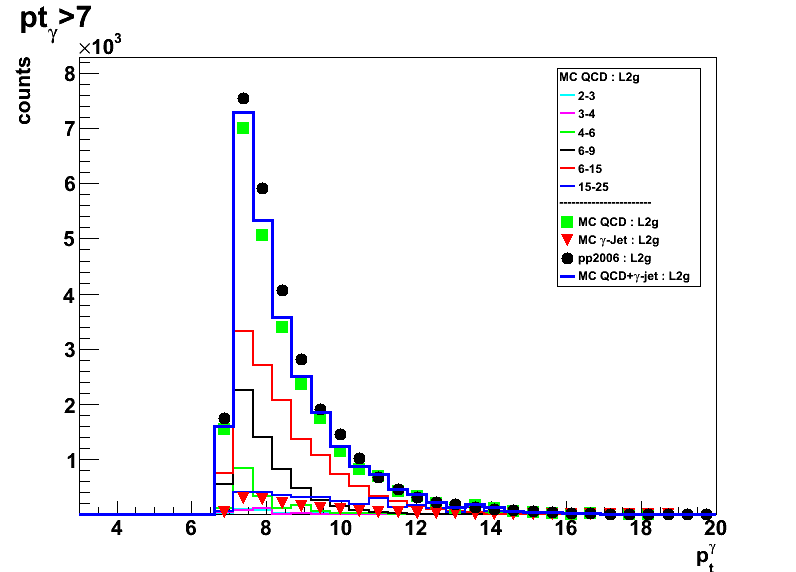

All figures:

- All pre-shower conditions combined, pre1<10MeV

- Left plots: no gamma pt cut

Right plots: pt_gamma >7GeV - Thick blue line shows MC sum: QCD + gamma-jet

- Thin solid color lines shows distributions from various partonic pt bins for QCD MC

See figures legend for color coding

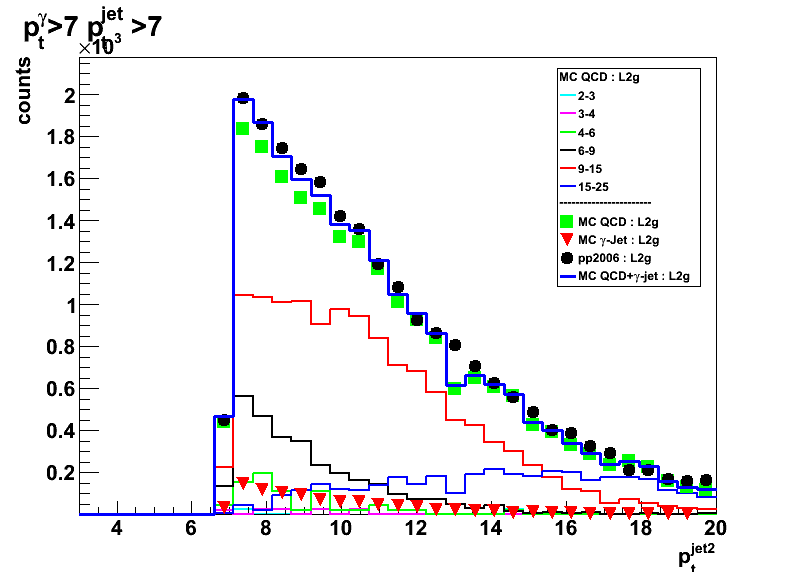

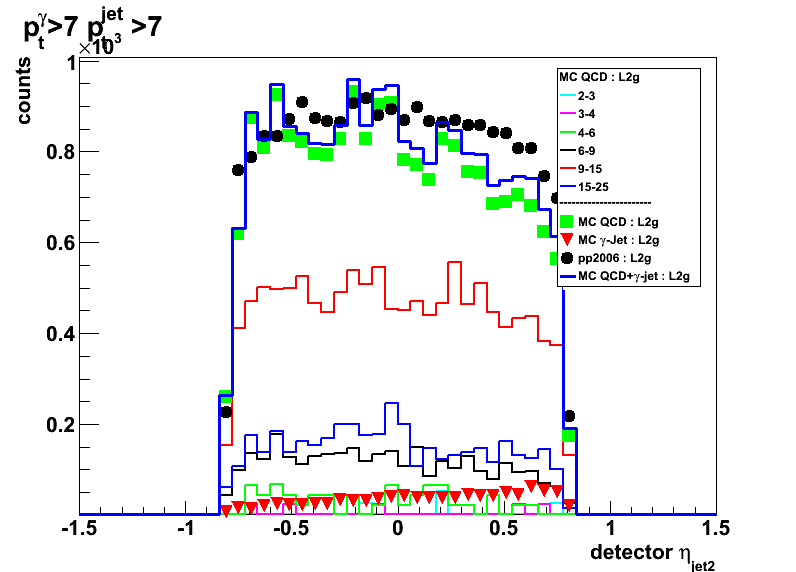

2009.01.27 gamma and jet pt plots with |eta|_jet < 0.7

Ilya Selyuzhenkov January 27, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV or no pt cuts

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

- cos (phi_jet - phi_gamma) < -0.8

- |eta_jet|< 0.7

- |v_z| < 100

Figures

All figures:

- All pre-shower conditions combined, pre1<10MeV

- Left plots: no gamma pt cut

Right plots: pt_gamma >7GeV - Thick blue line shows MC sum: QCD + gamma-jet

- Thin solid color lines shows distributions from various partonic pt bins for QCD MC

See figures legend for color coding

Figure 1: Vertex z distribution

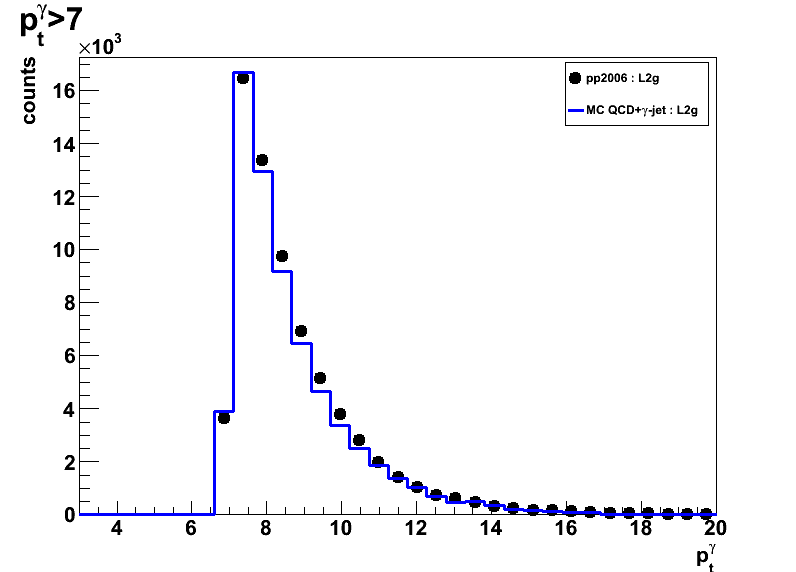

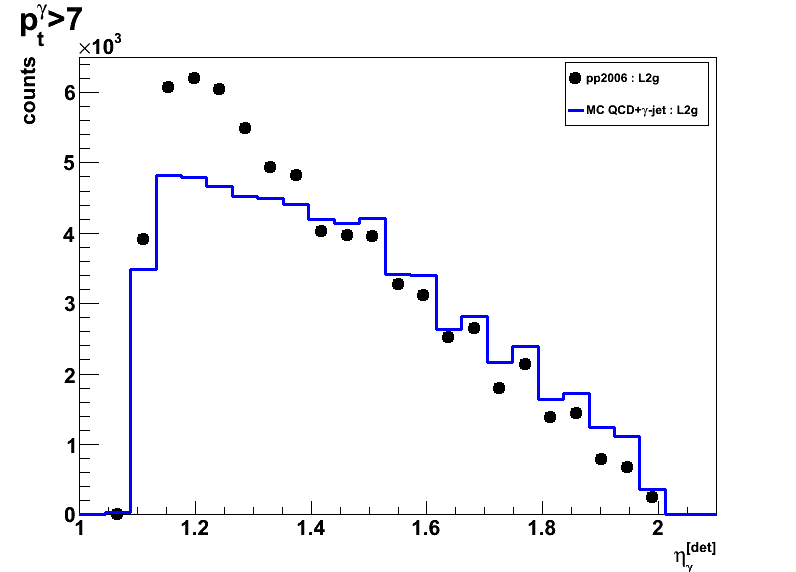

Figure 4:Photon pt

Same as in Fig.4 on a log scale: no gamma pt cut and pt>7GeV

Figure 5: Away side jet pt

Same as in Fig.5 on a log scale: no gamma pt cut and pt>7GeV

02 Feb

February 2009 posts

2009.02.02 No pre-shower cuts, Normalization fudge factor 1.24

Ilya Selyuzhenkov February 02, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

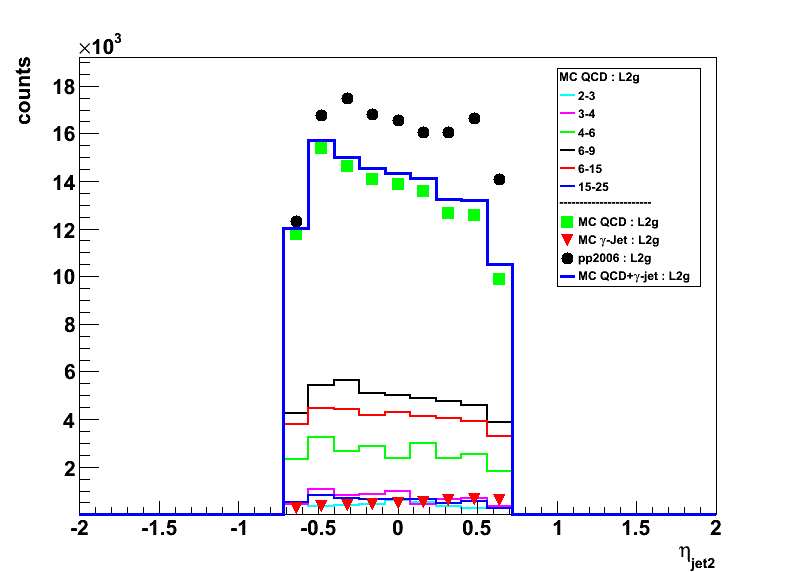

Figures

All figures:

- All pre-shower conditions combined, No pre-shower cuts

- Thick blue line shows MC sum: QCD + gamma-jet

- Black solid circles: pp2006 data

- Monte-Carlo results first scaled to 3.164 pb^-1 according to Pythia luminosity

and then an additional fudge factor of 1.24 has been applied.

Fudge factor is defined as the yields ratio from data to scaled with Pythia luminosity Monte-Carlo

for pt_jet>7GeV and pt_gamma>7 candidates

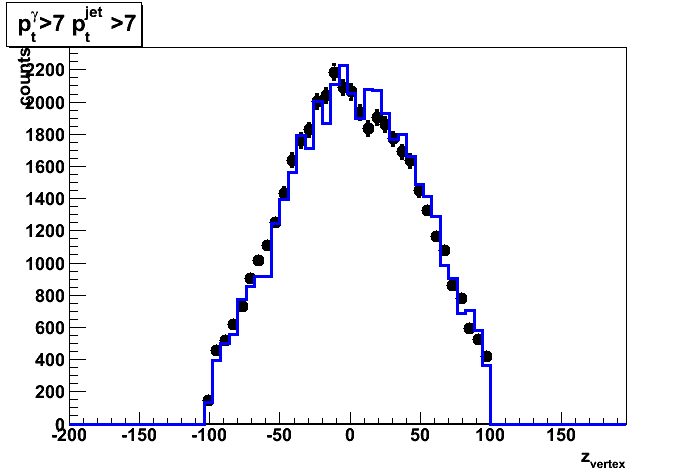

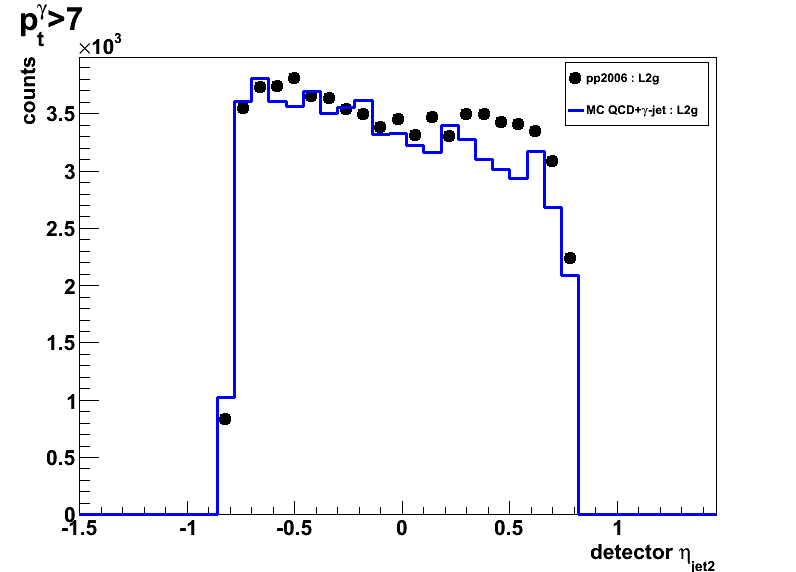

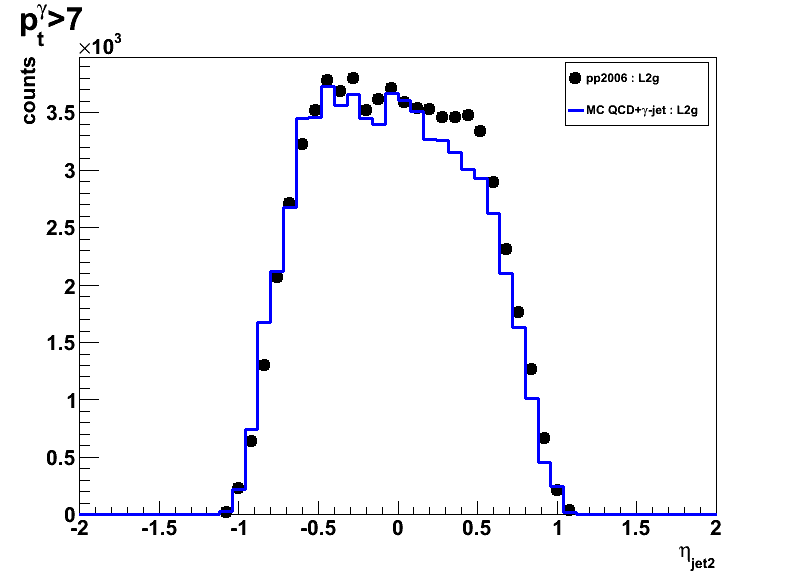

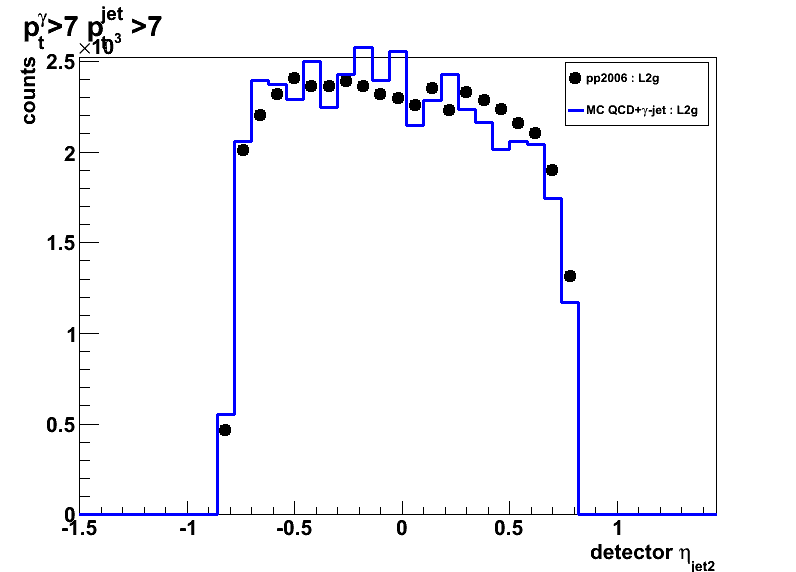

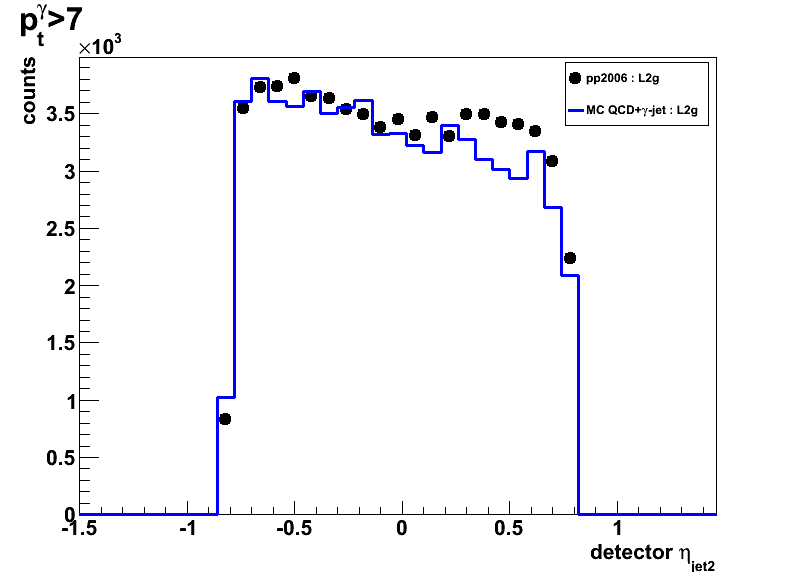

Figure 1: Vertex z distribution with pt_jet>7 cut (left) and without pt_jet cut (rigth)

Figure 2: Photon (left) and away side jet (right) pt

Figure 3: Photon detector eta (left) and corrected for vertex eta (right)

Figure 4: Away side jet detector eta (left) and corrected for vertex eta (right)

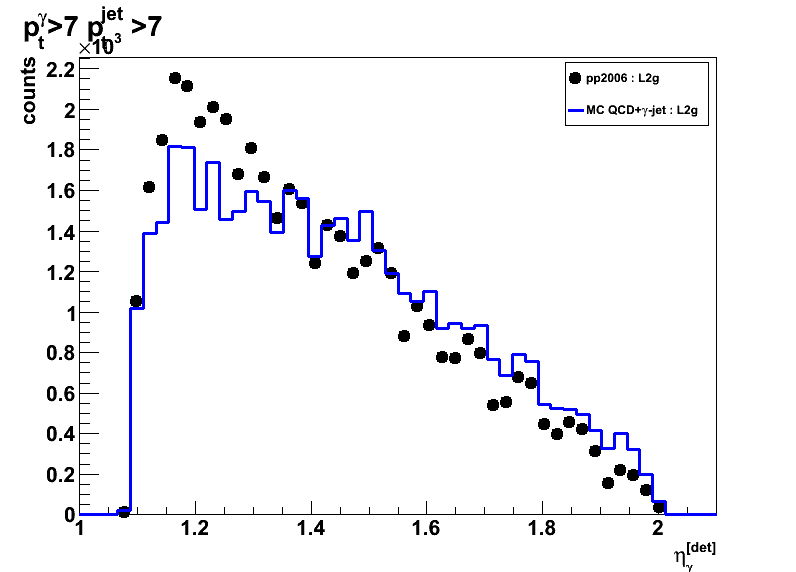

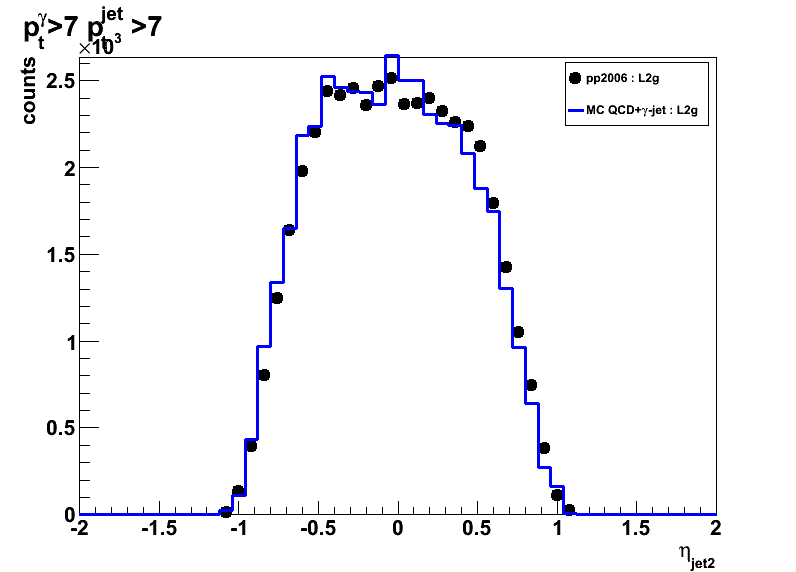

2009.02.03 No pre-shower cuts, pt_jet >7 vs. No pt_jet cuts

Ilya Selyuzhenkov February 03, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - gamma-jet[gamma-filtered] - data-driven Prompt Photon [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV. - QCD jets[gamma-filtered] - data-driven QCD [p6410EemcGammaFilter] events.

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered pp2006 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

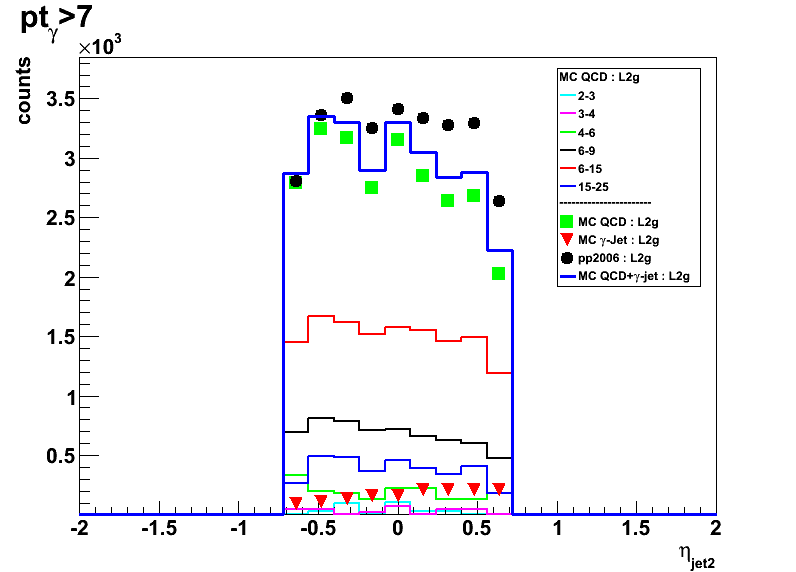

Figures

Each figure has:

- All pre-shower conditions combined, No pre-shower cuts

- Thick blue line shows MC sum: QCD + gamma-jet

- Black solid circles shows pp2006 data

- Left plots: pt_jet>7GeV

Right plots: no cuts on pt_jet - Monte-Carlo results for QCD and gamma-jet samples are first

scaled to 3.164 pb^-1 according to Pythia luminosity,

added together, and then an additional fudge factor of 1.24 applied.

Fudge factor is defined as pp2006 to Monte-Carlo sum ratio

for pt_jet>7GeV and pt_gamma>7 candidates

Figure 1: Vertex z distribution

Figure 3: Corrected for vetrex photon eta

Figure 4: Away side jet detector eta

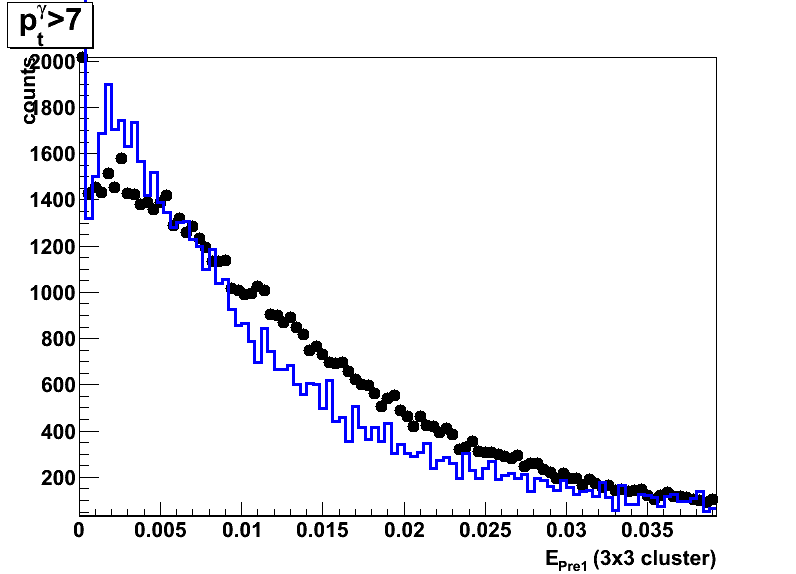

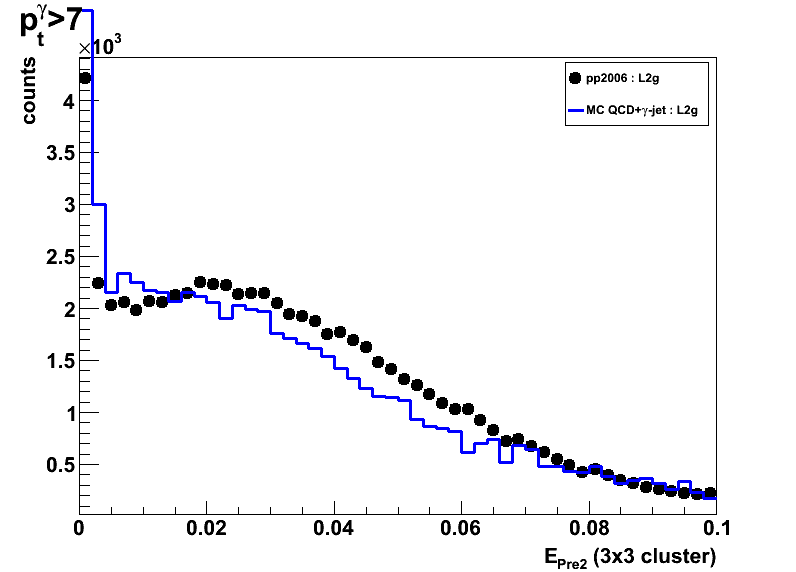

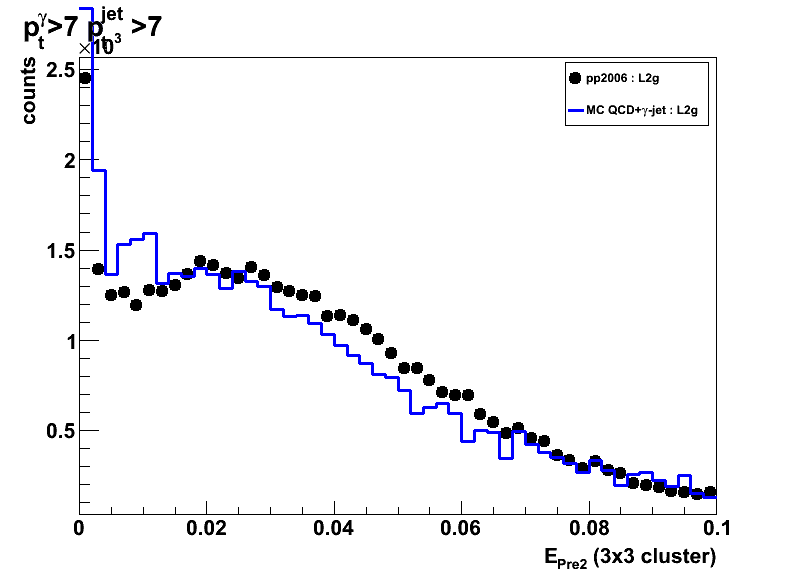

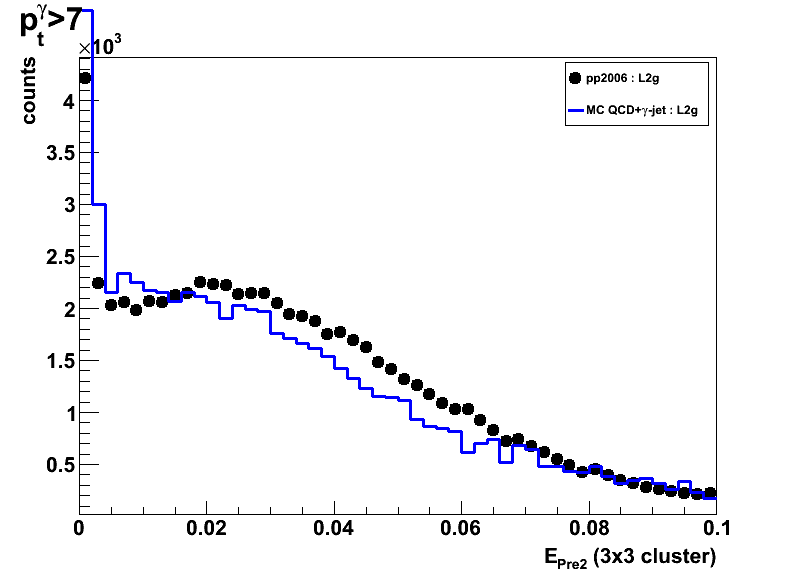

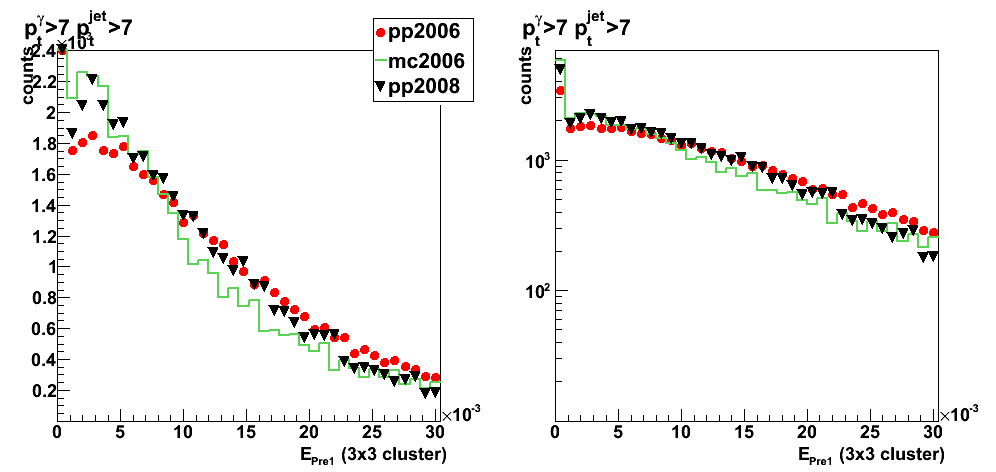

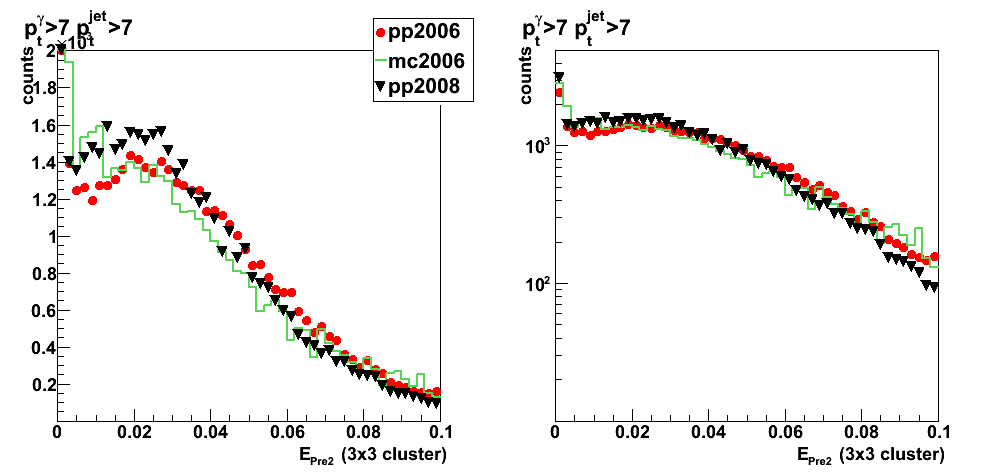

2009.02.06 Pre-shower energy distribution Run6 vs. Run8 geometry

Ilya Selyuzhenkov February 06, 2009

Data sets

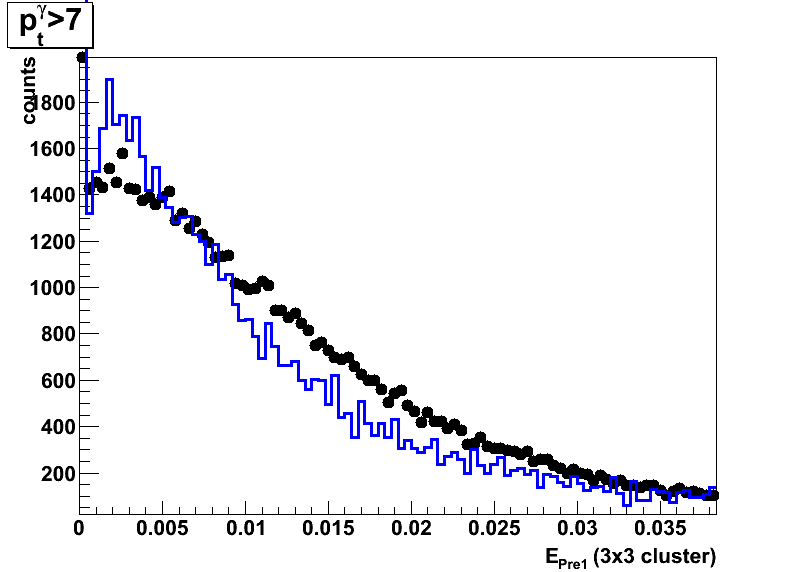

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - mc2006: gamma-jet+QCD jets [p6410EemcGammaFilter] events.

- pp2008 - STAR 2008 pp data

Trigger: etot-mb-l2 [id:7]

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

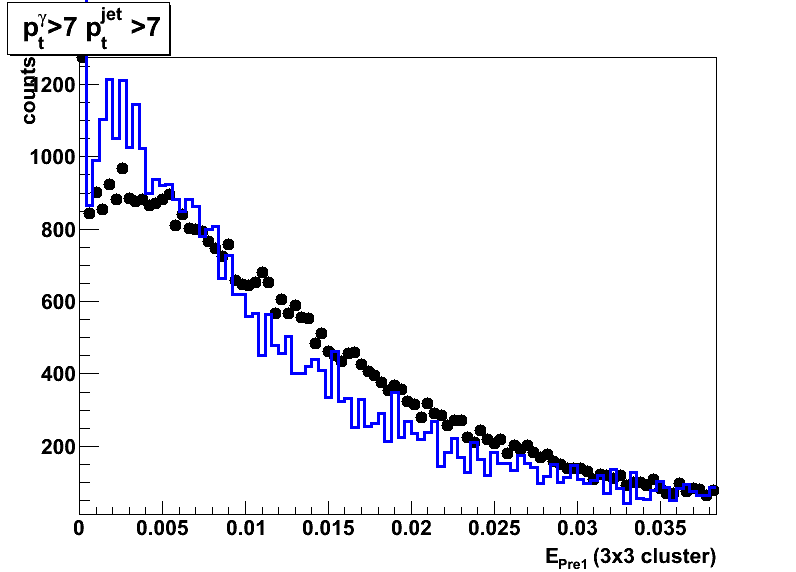

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV, jet pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered for pp2006 and pp2008 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

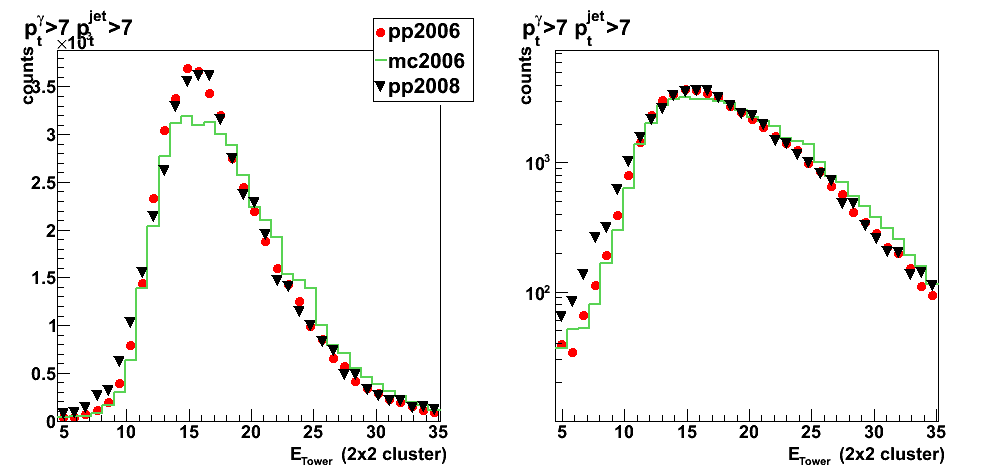

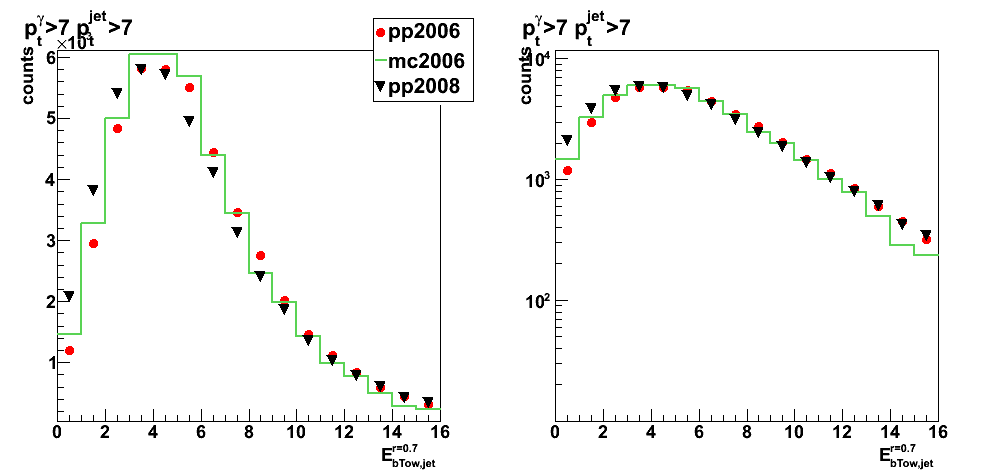

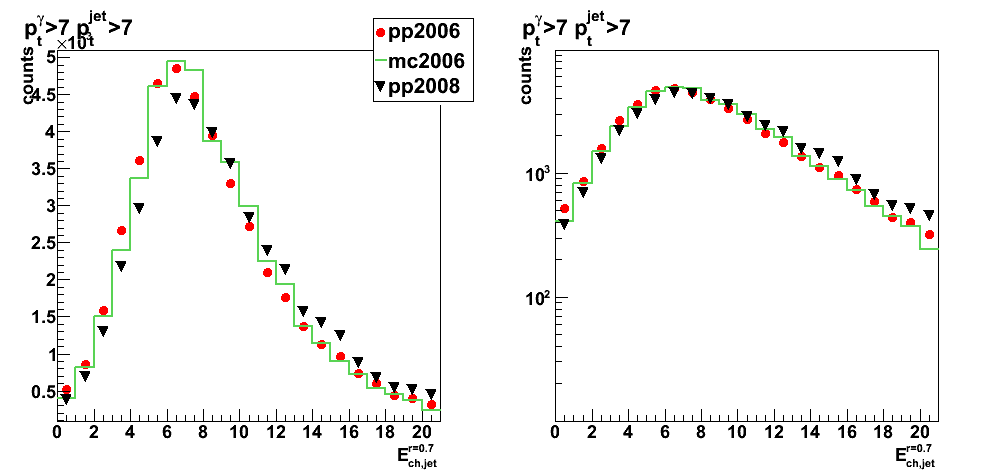

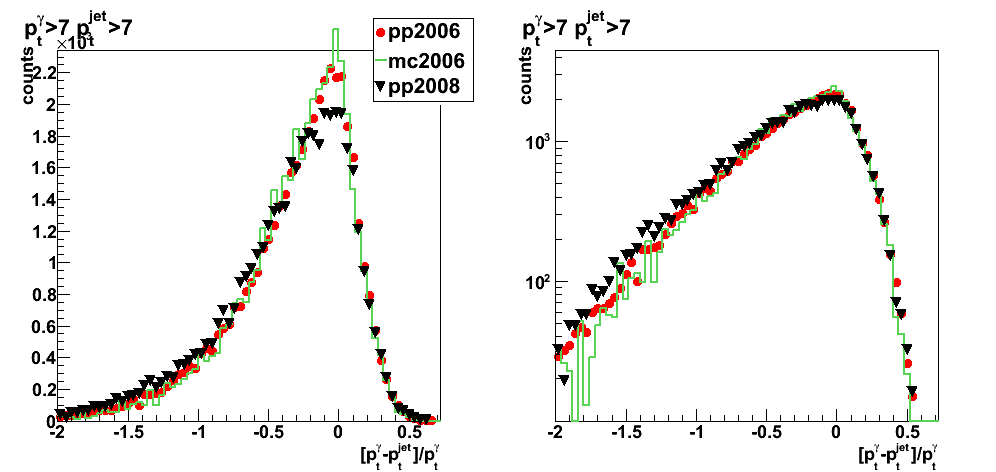

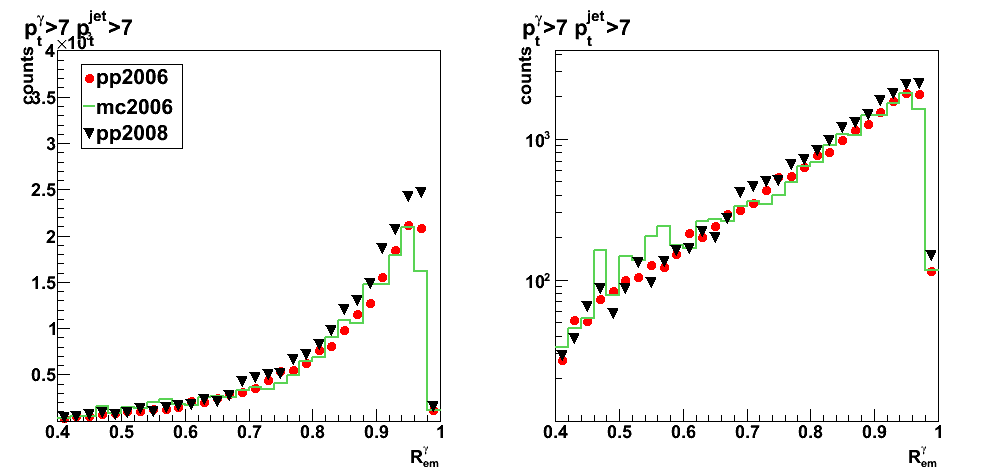

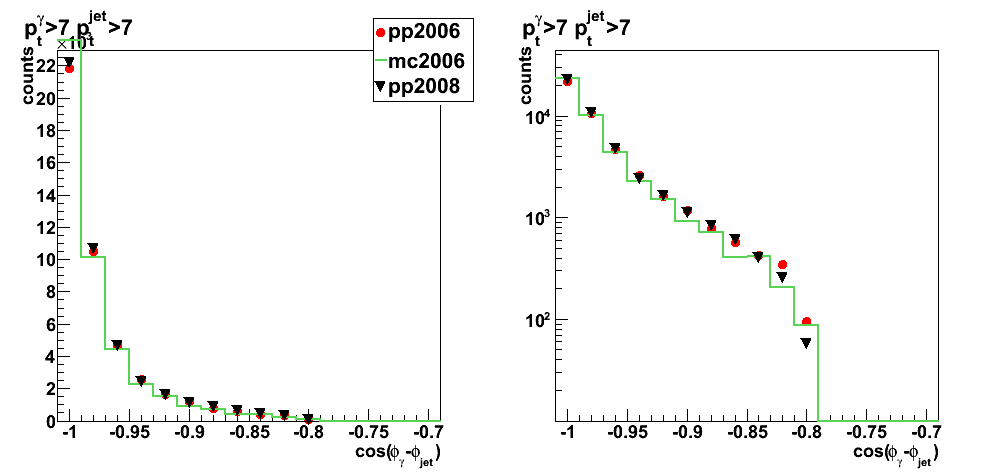

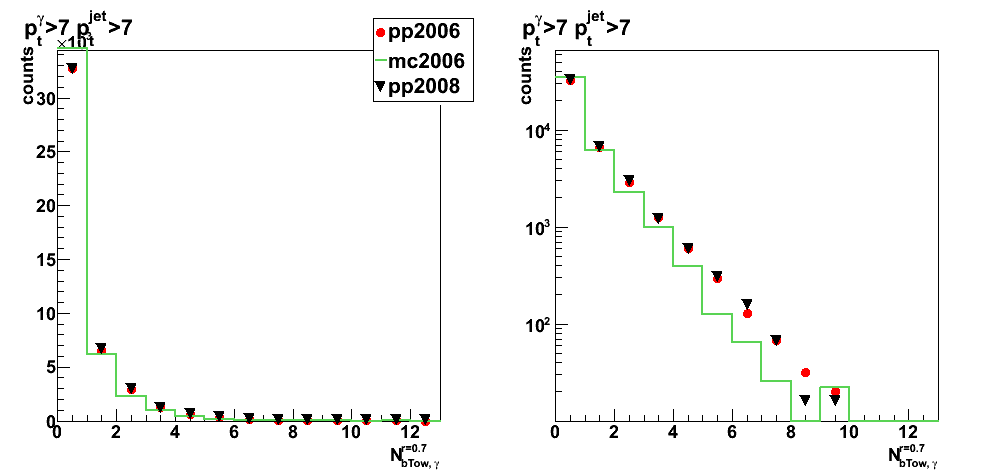

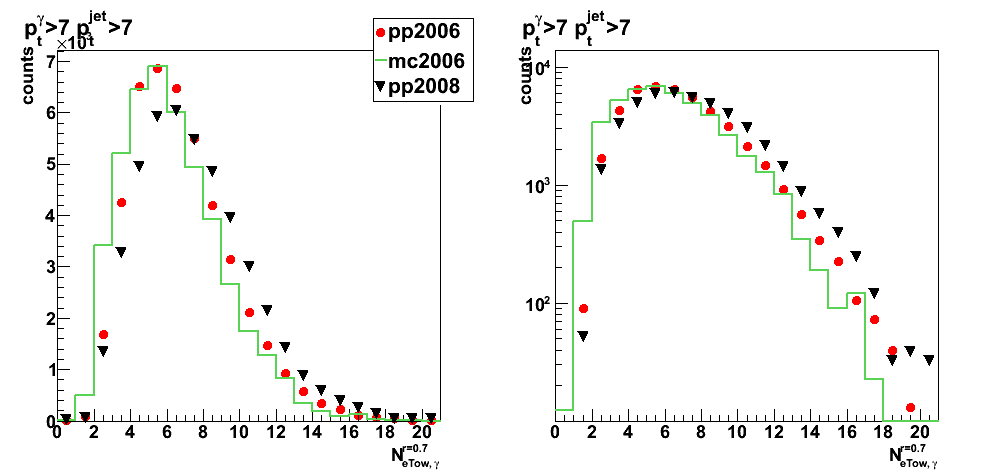

Figures

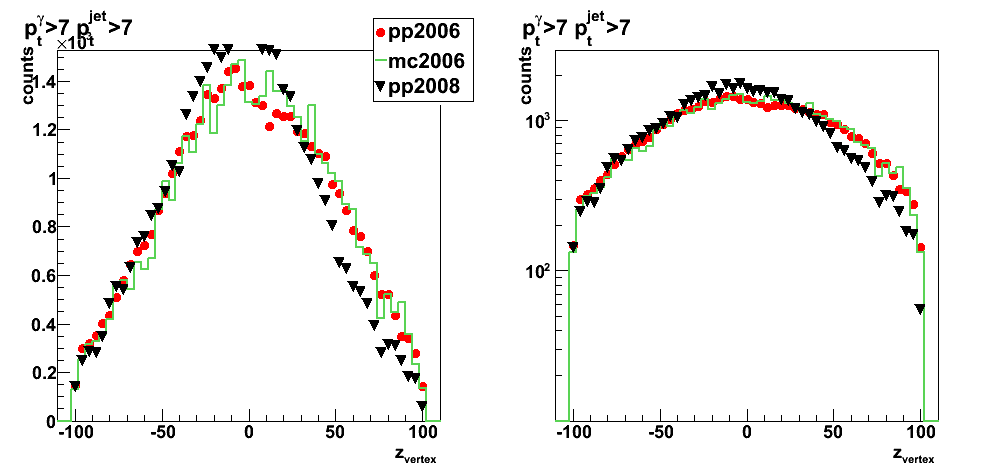

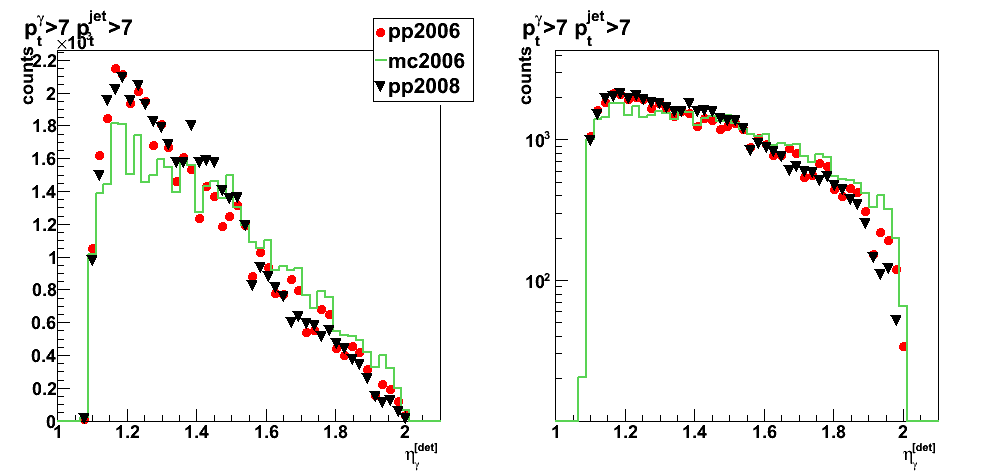

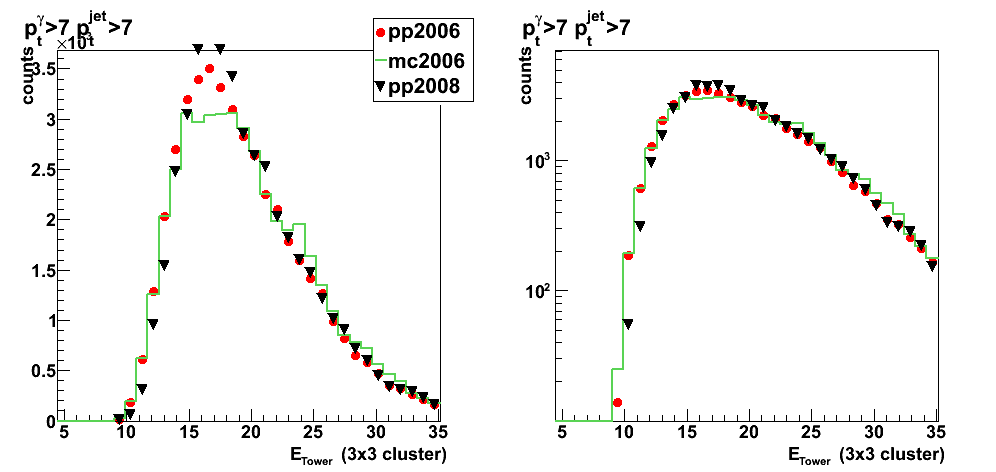

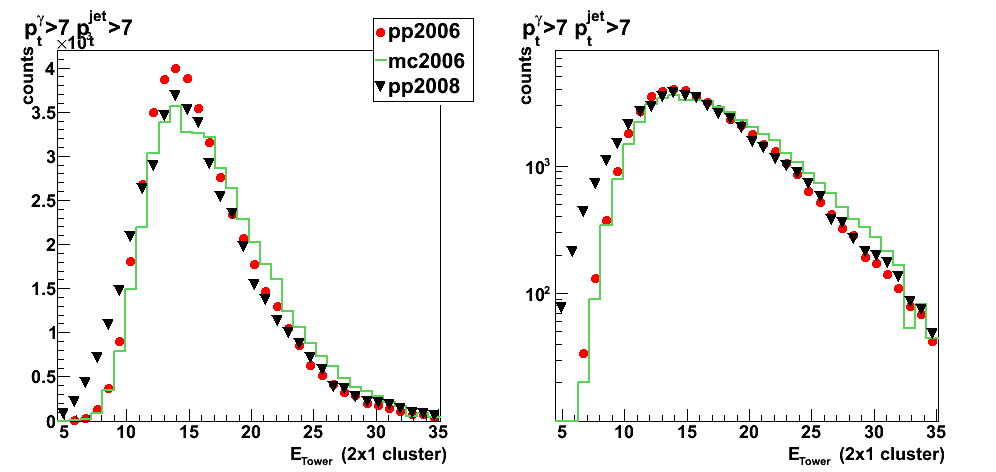

Each figure has:

- All pre-shower conditions combined, No pre-shower cuts

- Red circles show pp2006 data

- Black triangles show pp2008 data

Data scaled to match the integraled yield from pp2006 data - Green line shows MC sum: QCD + gamma-jet

Monte-Carlo results for QCD and gamma-jet samples are first

scaled to 3.164 pb^-1 according to Pythia luminosity,

added together, and then an additional fudge factor of 1.24 applied.

Fudge factor is defined as pp2006 to Monte-Carlo sum ratio

for pt_jet>7GeV and pt_gamma>7 candidates

Observations

- Pre-shower energy distributions from pp2008 data set

are narrower than that for pp2006 data.

This corresponds to smaller amount of material budget in y2008 STAR geometry. - Pre-shower energy distribution from Monte-Carlo with y2006 geometry

closer follows the distribution from pp2008 data set, rather than that from pp2006 data.

This indicates the lack of material budget in y2006 Monte-Carlo.

Note: There is a "pre-shower sector 10 problem" for pp2008 data,

which results in migration of small fraction of events with pre-shower>0 into

pre-shower=0 bin (first zero bins in Fig.1 and 2. below).

For pre-shower>0 case this only affects overall normalization of pp2008 data,

but not the shape of pre-shower energy distributions.

I'm running jet-finder+my software to get more statistics from pp2008 data set,

and after more QA will produce list of runs with "pre-shower sector 10 problem",

so to exclude them in the next iteration of my plots.

2009.02.09 pp2006, pp2008, amd mc2006 comparison

Ilya Selyuzhenkov February 06, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - mc2006: gamma-jet+QCD jets [p6410EemcGammaFilter] events.

- pp2008 - STAR 2008 pp data

Trigger: etot-mb-l2 [id:7]

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV, jet pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered for pp2006 and pp2008 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

Figures

Each figure has:

- All pre-shower conditions combined, No pre-shower cuts

- Red circles show pp2006 data

- Black triangles show pp2008 data

Data scaled to match the integraled yield from pp2006 data - Green line shows MC sum: QCD + gamma-jet

Monte-Carlo results for QCD and gamma-jet samples are first

scaled to 3.164 pb^-1 according to Pythia luminosity,

added together, and then an additional fudge factor of 1.24 applied.

Fudge factor is defined as pp2006 to Monte-Carlo sum ratio

for pt_jet>7GeV and pt_gamma>7 candidates

Kinematics

Figure 6: gamma-jet pt balance

Figure 7: Photon neutral energy fraction

Figure 8: Jet neutral energy fraction

Figure 9: cos(phi_gamma-phi_jet)

Photon candidate's 2x1, 2x2, and 3x3 tower cluser energy

Number of charge tracks, Barrel and Endcap towers within r=0.7 for photon and gamma

Figure 13: Number of charged track associated with photon candidate

Figure 14: Number of Barrel towers associated with photon candidate

Figure 15: Number of Endcap towers associated with photon candidate

Jet energy composition

2009.02.16 pt_jet>5GeV: pre-shower sorting with new normalization

Ilya Selyuzhenkov February 16, 2009

Data sets

- pp2006 - STAR 2006 pp longitudinal data (~ 3.164 pb^1)

Trigger: eemc-http-mb-L2gamma [id:137641] - mc2006: gamma-jet+QCD jets [p6410EemcGammaFilter] events.

- pp2008 - STAR 2008 pp data

Trigger: etot-mb-l2 [id:7]

Partonic pt range 2-25 GeV.

Cuts applied

- Di-jet events

- Require to reconstruct photon momentum (no gamma-jet isolation cuts)

- Gamma pt > 7GeV, jet pt > 7GeV

- L2gamma emulation in Monte-Carlo

- L2gamma triggered for pp2006 and pp2008 events

- cos (phi_jet - phi_gamma) < -0.8

- detector |eta_jet|< 0.8

- |v_z| < 100

Figures

Each figure has:

- pp2008 data scaled to match the integraled yield from pp2006 data

- mc2006 stand for MC sum: QCD + gamma-jet

Monte-Carlo results for QCD and gamma-jet samples are first

scaled to 3.164 pb^-1 according to Pythia luminosity,

added together, and then an additional fudge factor of 1.24 applied.

Fudge factor is defined as pp2006 to Monte-Carlo sum ratio

for pt_jet>7GeV and pt_gamma>7 candidates

plots for pt_gamma>7GeV, pt_jet > 5GeV

- All pre-shower combined: 1D distributions

- All pre-shower combined: 2D correlations

- Pre-shower sorting 1D distributions

2009.02.19 Photon-jet analysis status update for Spin PWG

Photon-jet analysis status update for Spin PWG (February 19, 2009)

Slides: download pdf

Link for CIPANP abstract

CIPANP 2009 abstract on photon-jet measurement

CIPANP 2009 abstract on photon-jet study

Title:

"Photon-jet coincidence measurements

in polarized pp collisions at sqrt{s}=200GeV

with the STAR Endcap Calorimeter"

Abstract: download pdf

Previous versions: v1, v2, v3, v4

Conference link: CIPANP 2009

03 Mar

March 2009 posts

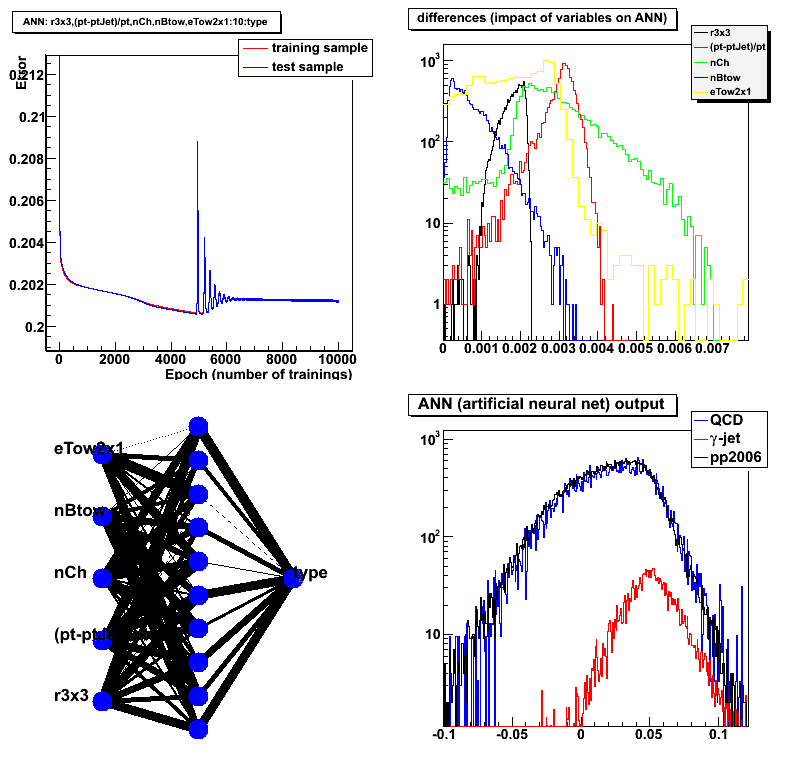

2009.03.02 Application of the neural network for the cut optimization (zero try)

Multilayer perceptron (feedforward neural networks)

Multilayer perceptron (MLP) is feedforward neural networks

trained with the standard backpropagation algorithm.

They are supervised networks so they require a desired response to be trained.

They learn how to transform input data into a desired response,

so they are widely used for pattern classification.

With one or two hidden layers, they can approximate virtually any input-output map.

They have been shown to approximate the performance of optimal statistical classifiers in difficult problems.

ROOT implementation for Multilayer perceptron

TMultiLayerPerceptron class in ROOT

mlpHiggs.C example

Application for cuts optimization in the gamma-jet analysis

Netwrok structure:

r3x3, (pt_gamma-pt_jet)/pt_gamma, nCharge, bBtow, eTow2x1: 10 hidden layers: one output later

Figure 1:

- Upper left: Learning curve (error vs. number of training)

Learing method is: Steepest descent with fixed step size (batch learning) - Upper right: Differences (how important are initial variableles for signal/background separation)

- Lower left: Network structure (ling thinkness corresponds to relative weight value)

- Lower right: Network output. Red - MC gamma-jets, blue QCD background, black pp2006 data

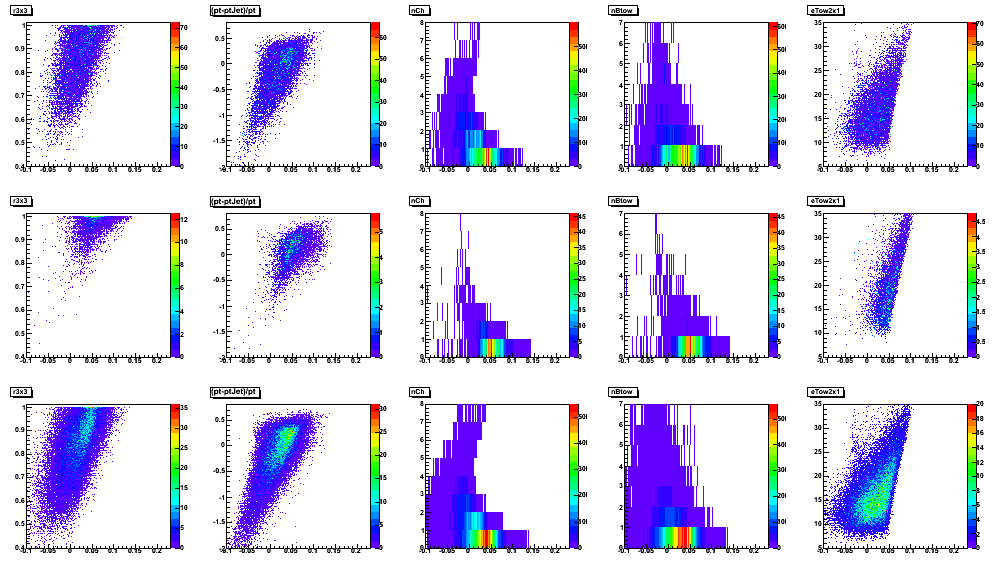

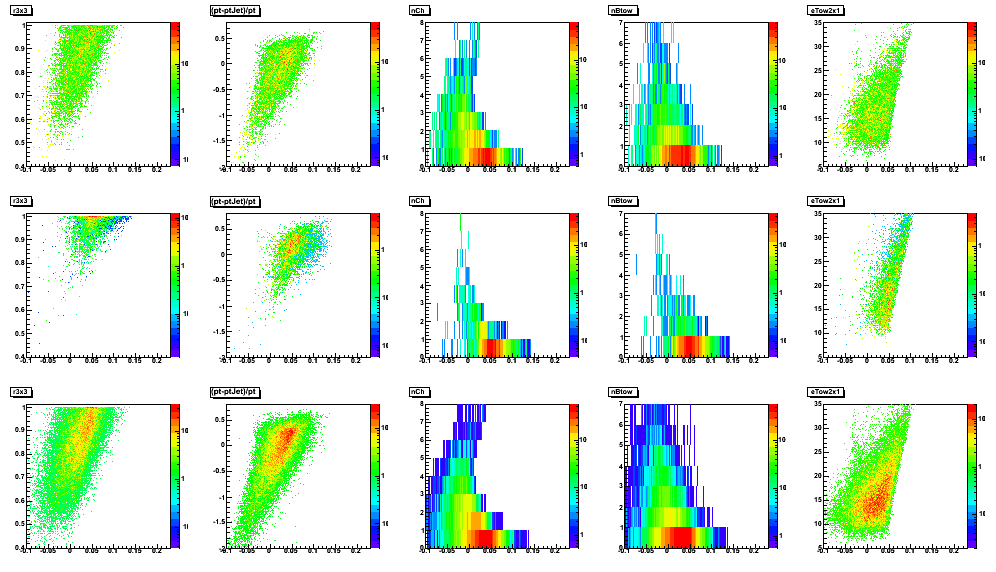

Figure 2: Input parameters vs. network output

Row: 1: MC QCD, 2: gamma-jet, 3 pp2006 data

Vertical axis: r3x3, (pt_gamma-pt_jet)/pt_gamma, nCharge, bBtow, eTow2x1

Horisontal axis: network output

2009.03.09 Application of the LDA and MLP classifiers for the cut optimization

Cut optimization with Fisher's LDA and MLP (neural network) classifiers

ROOT implementation for LDA and MLP:

- Fisher's Linear Discriminant Analysis (LDA)

- Multi-Layer Perceptron (MLP) [feed-forward neural network]

Application for cuts optimization in the gamma-jet analysis

LDA configuration: default

MLP configuration:

- 2 hidden layers [N+1:N neural network configuration, N is number of input parameters]

- Learning method: stochastic minimization (1000 learning cycles)

Input parameters (same for both LDA and MLP):

- Energy fraction in 3x3 cluster within a r=0.7 radius: r3x3

- Photon-jet pt balance: [pt_gamma-pt_jet]/pt_gamma

- Number of charge tracks within r=0.7 around gamma candidate

- Number of Endcap towers fired within r=0.7 around gamma candidate

- Number of Barrel towers fired within r=0.7 around gamma candidate

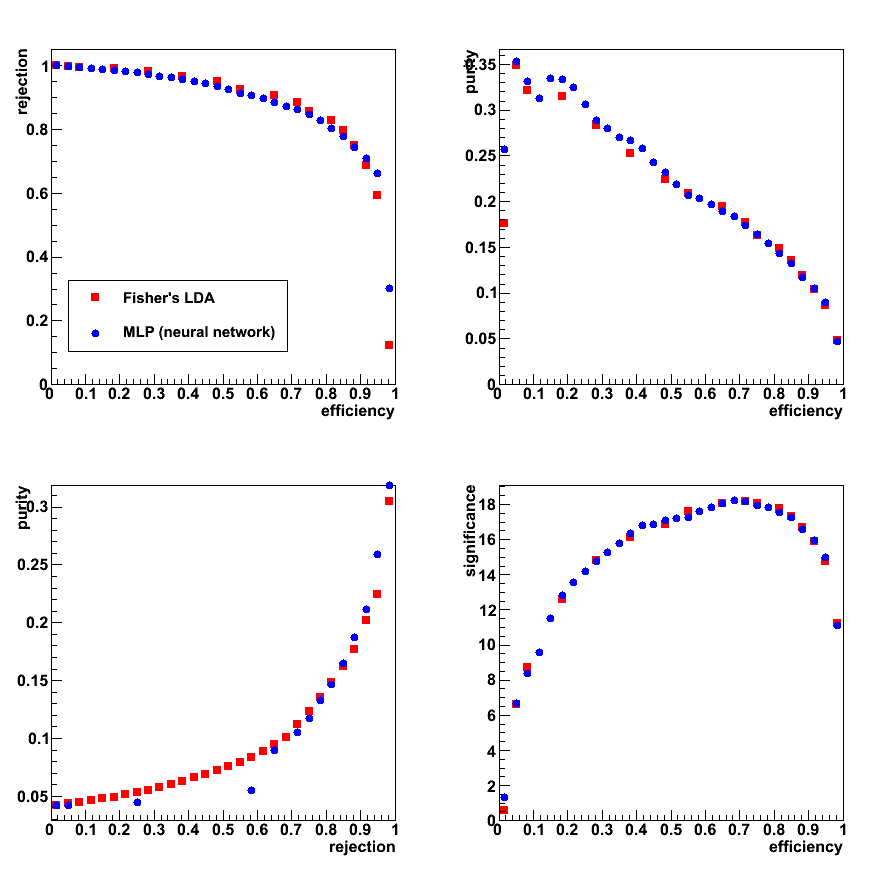

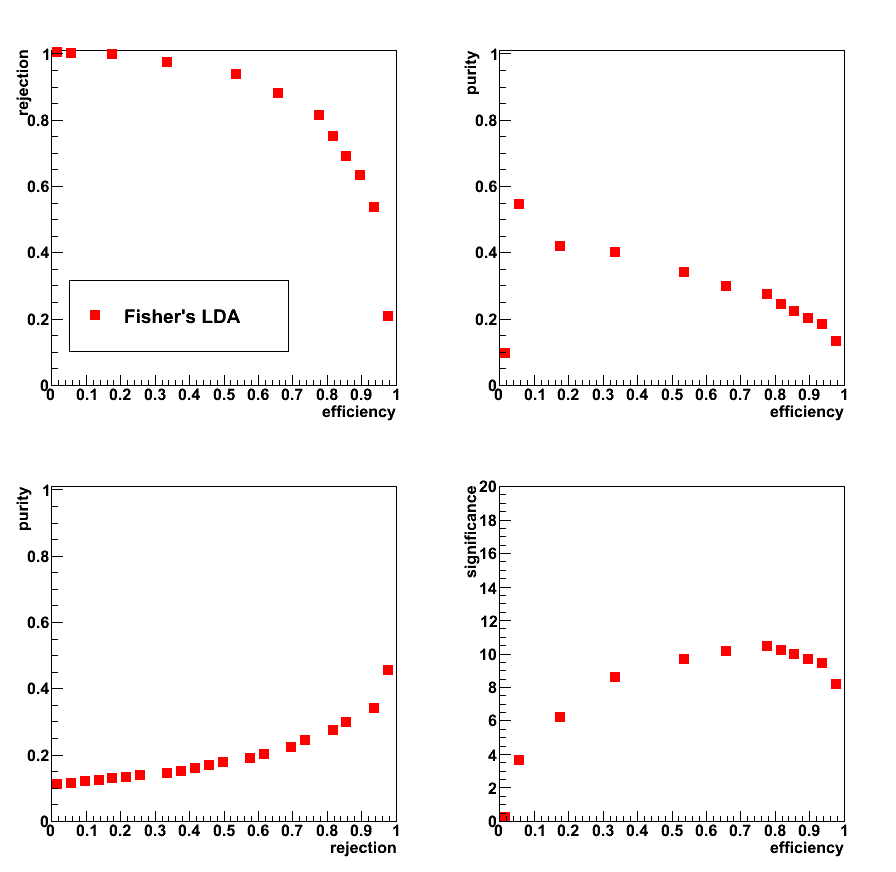

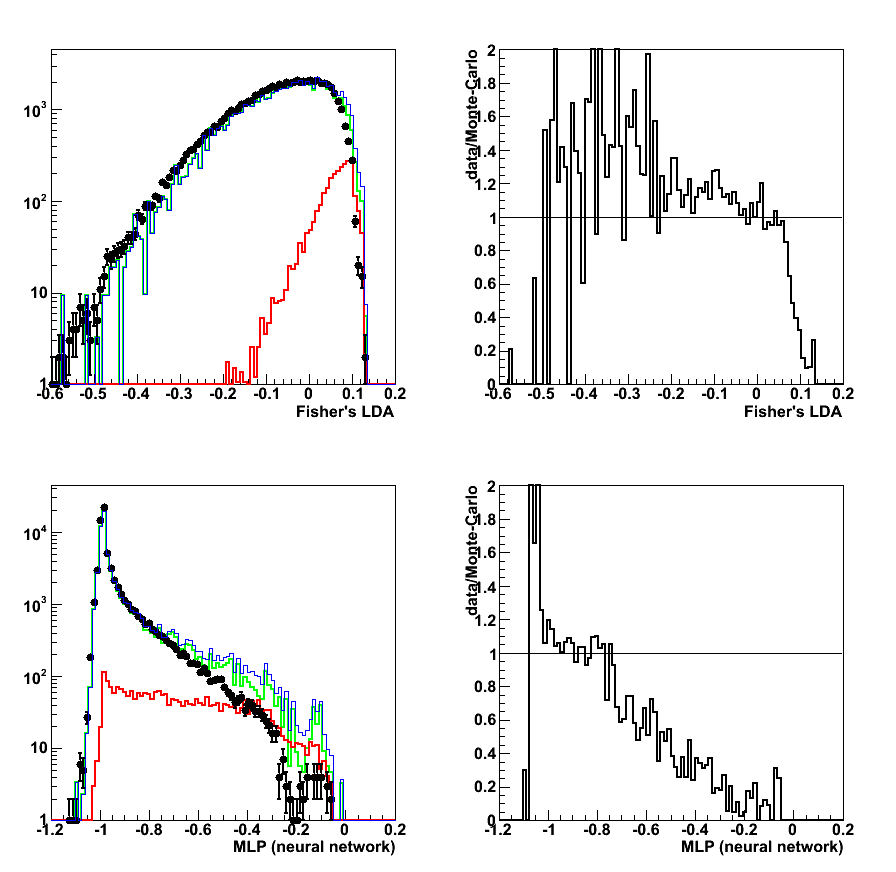

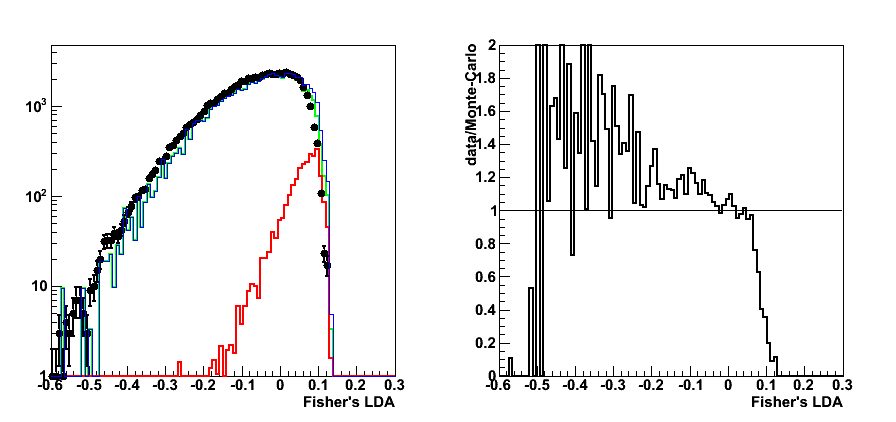

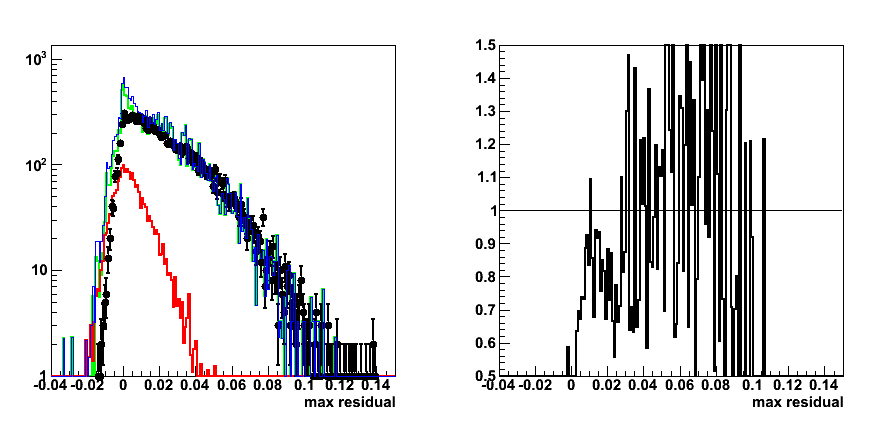

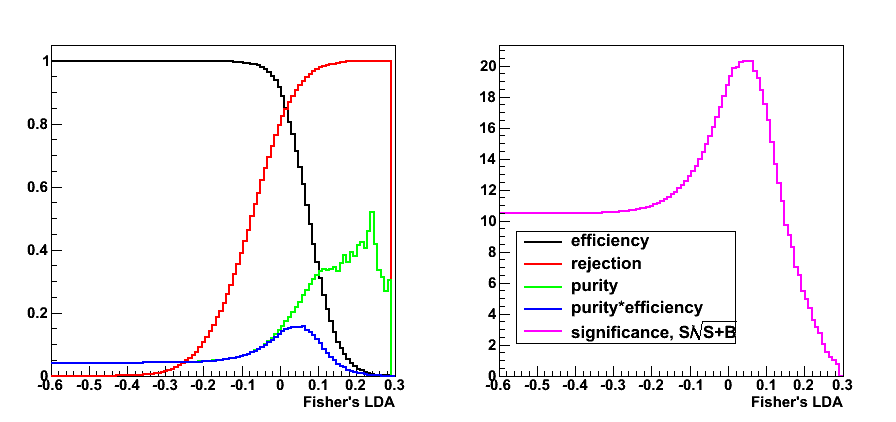

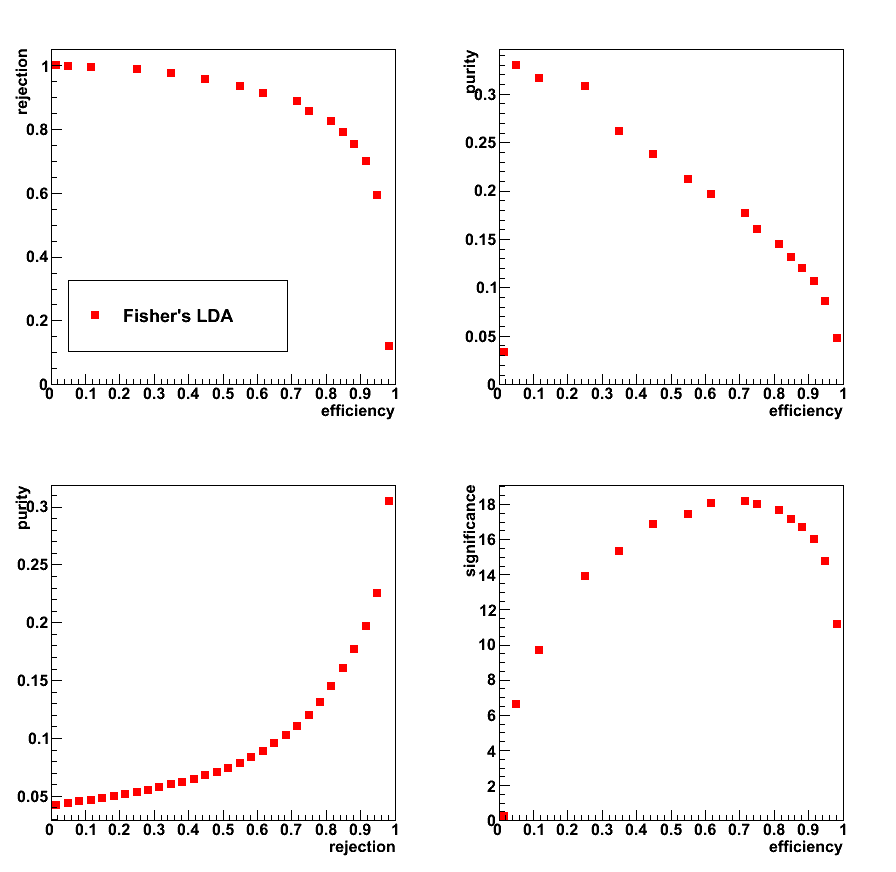

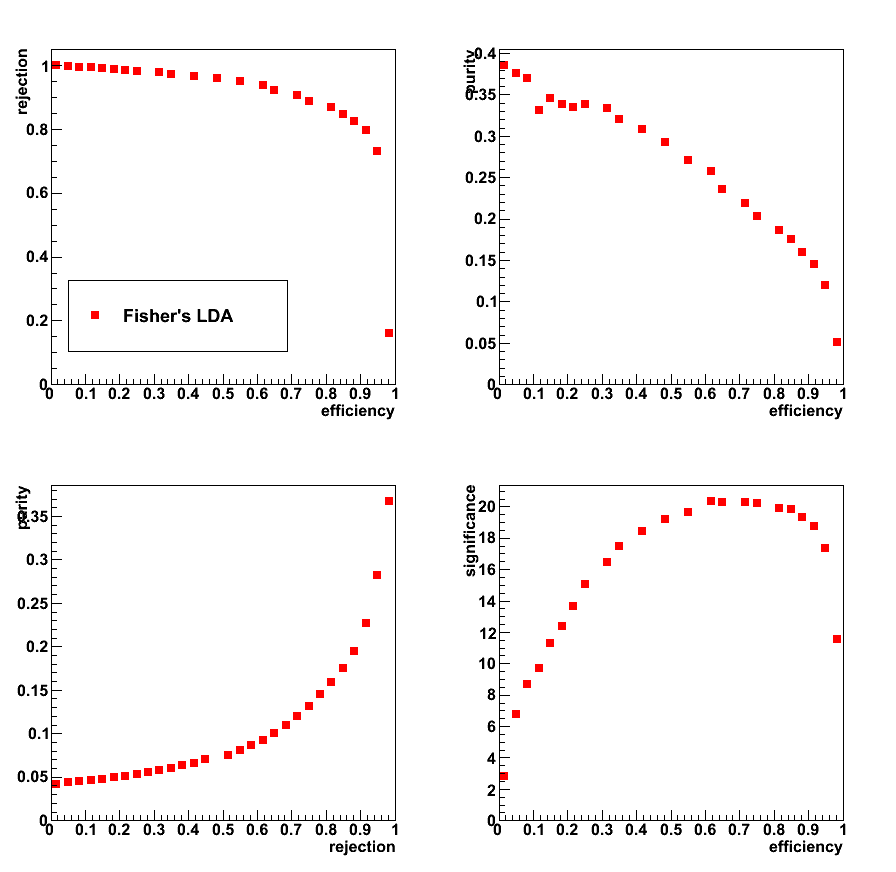

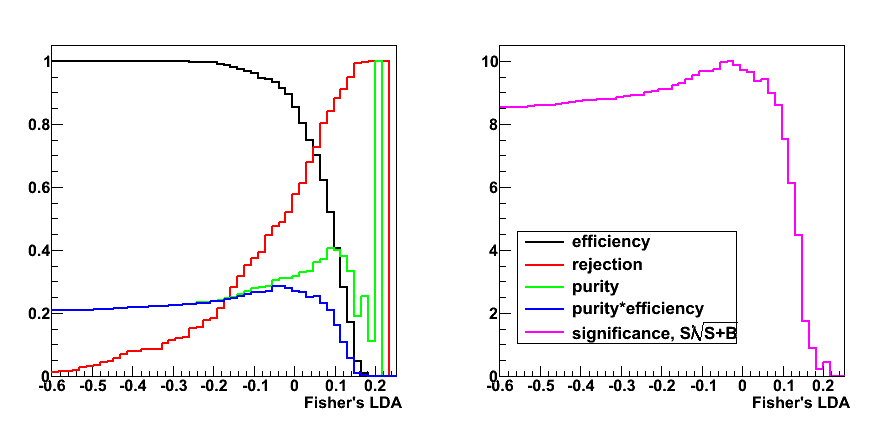

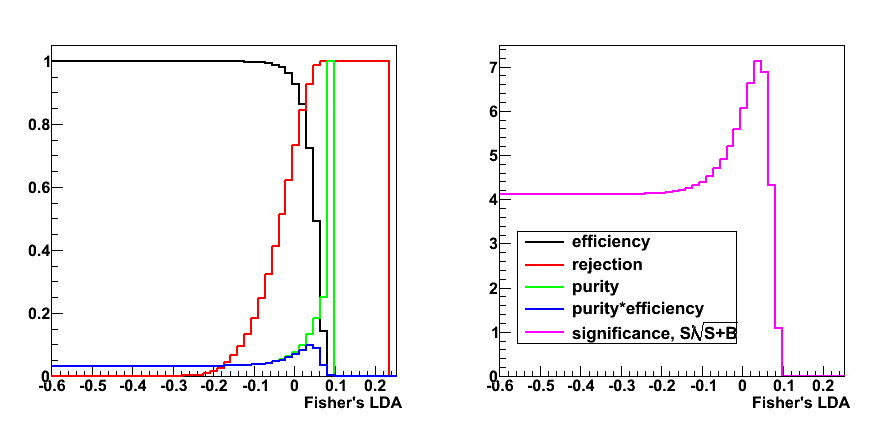

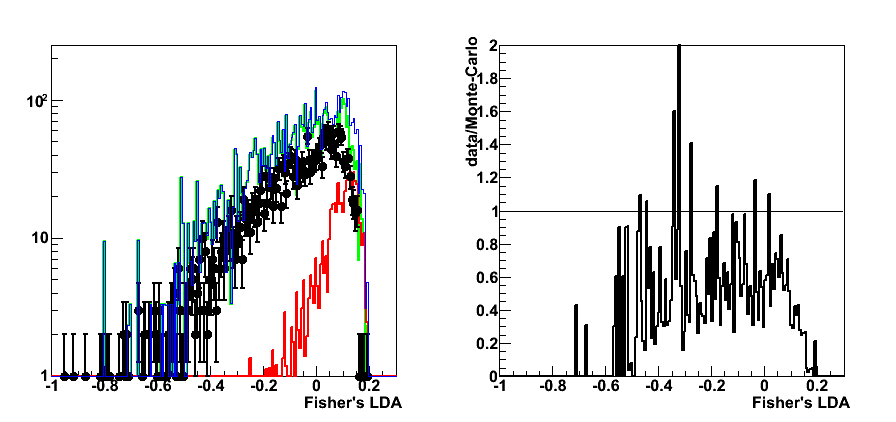

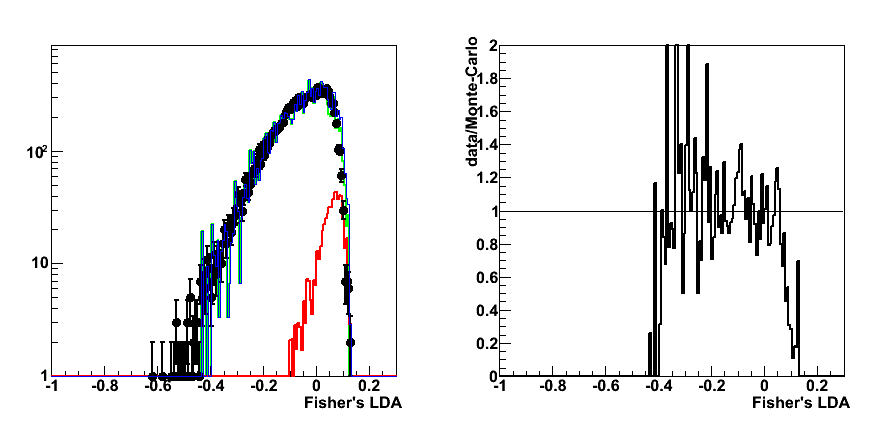

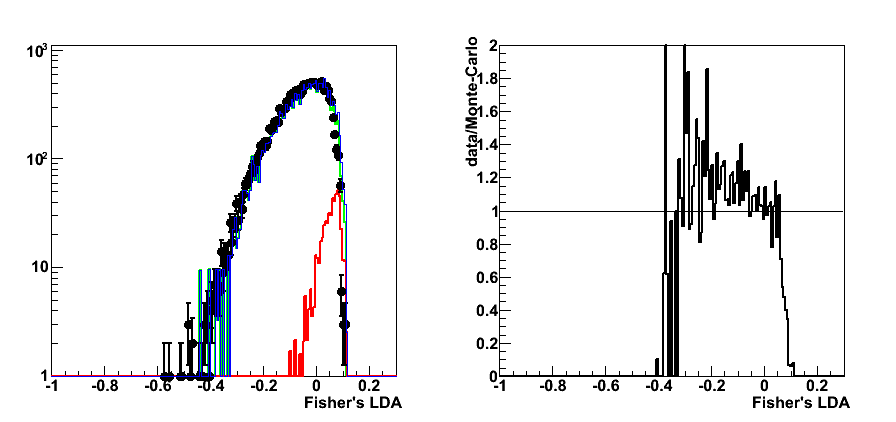

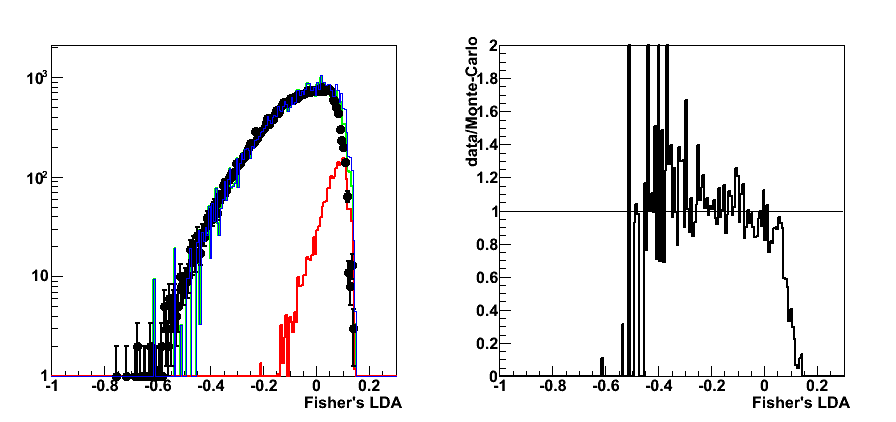

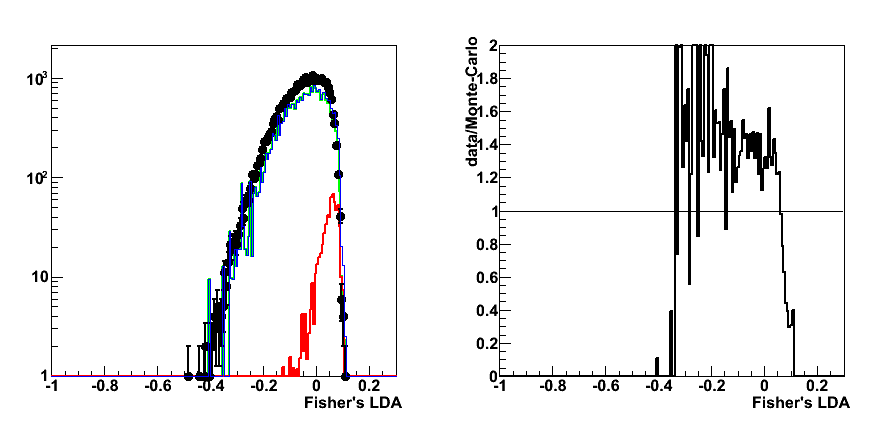

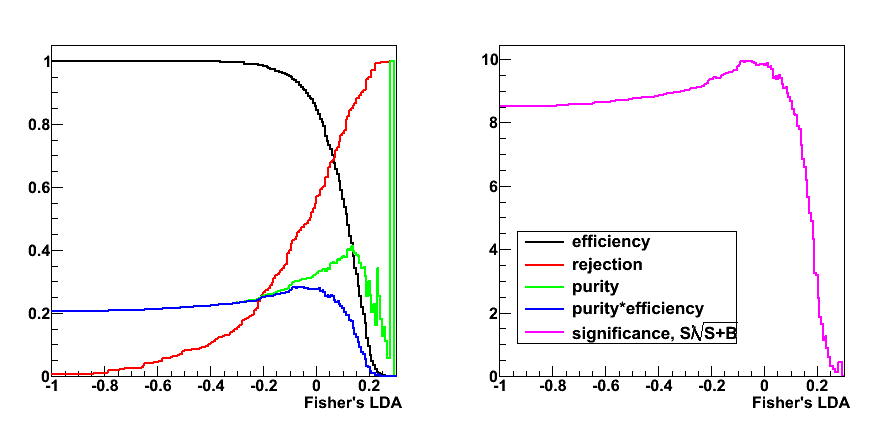

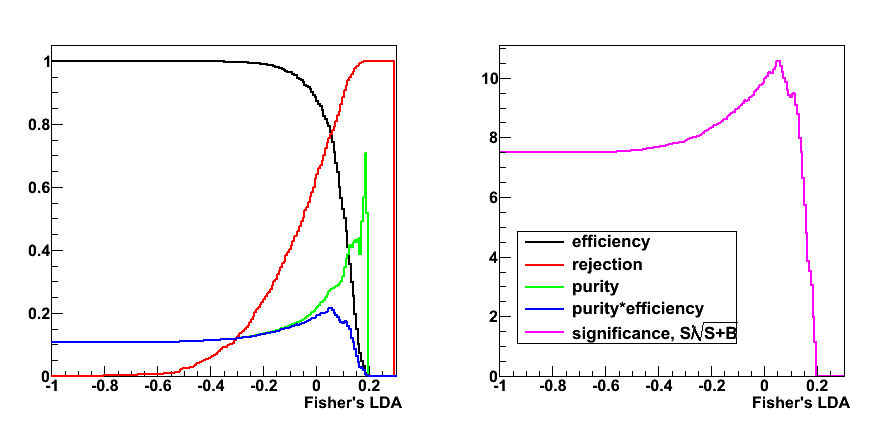

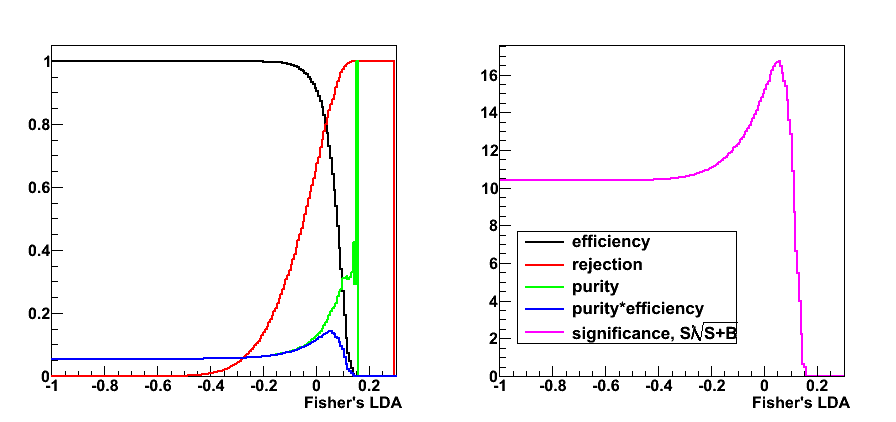

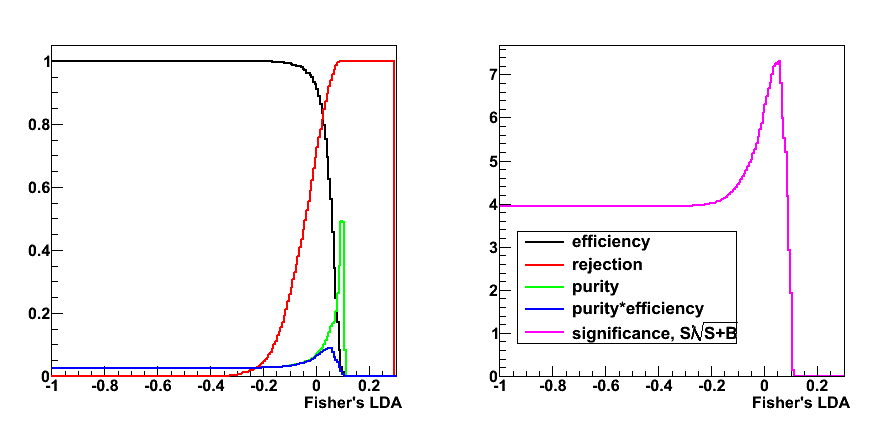

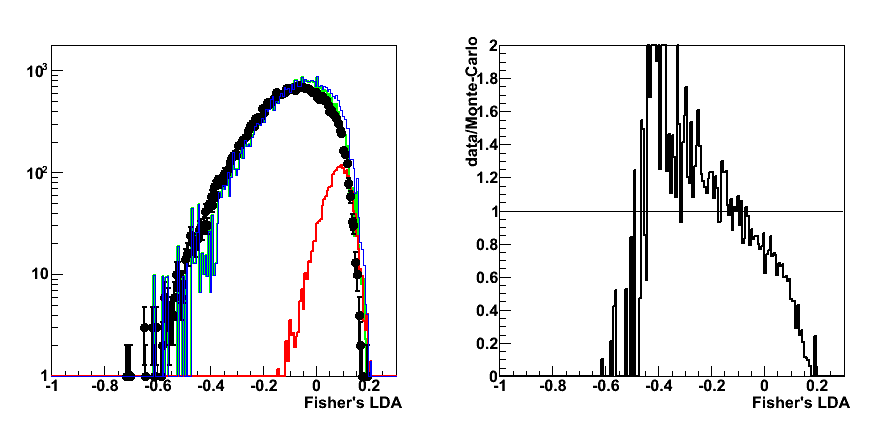

Figure 1: Signal efficiency and purity, background rejection (left),

and significance: Sig/sqrt[Sig+Bg] (right) vs. LDA (upper plots) and MLP (lower plots) classifier discriminants

Figure 2:

- Upper left: Rejection vs. efficiency

- Upper right: Purity vs. efficiency

- Lower left: Purity vs. Rejection

- Lower right: Significance vs. efficiency

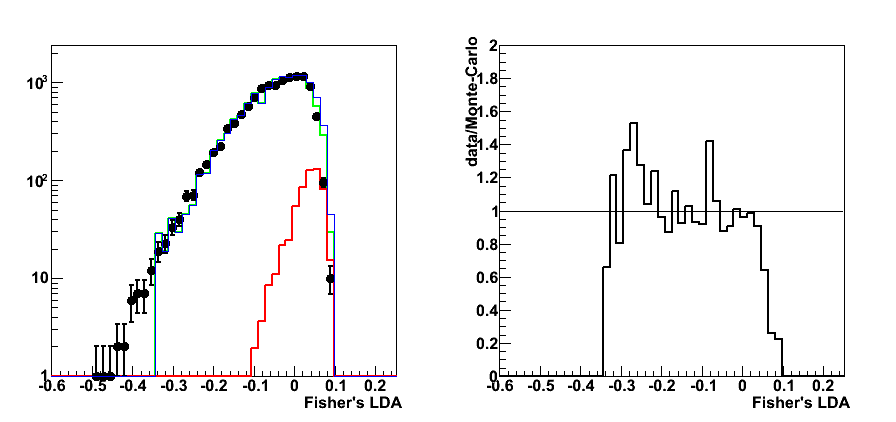

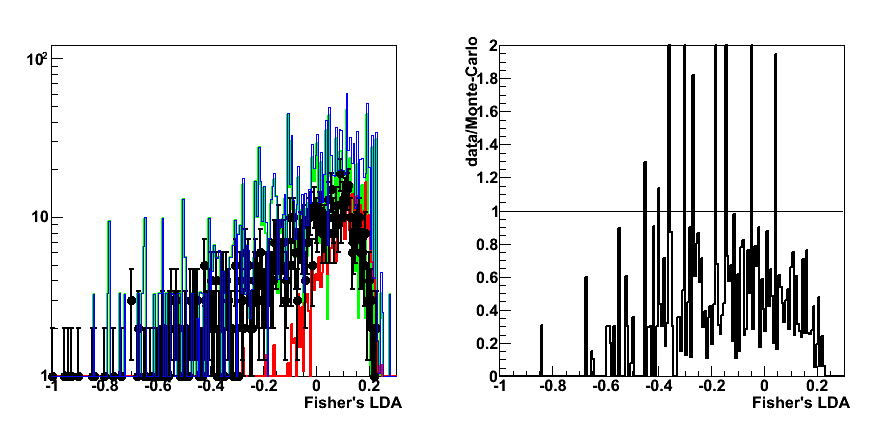

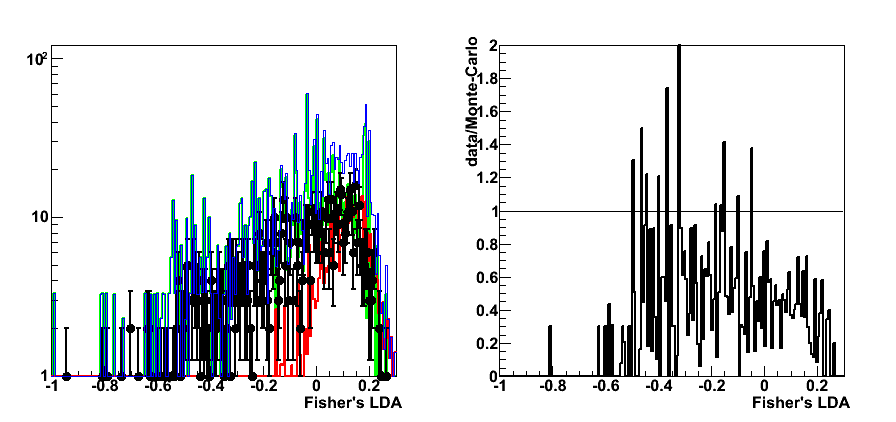

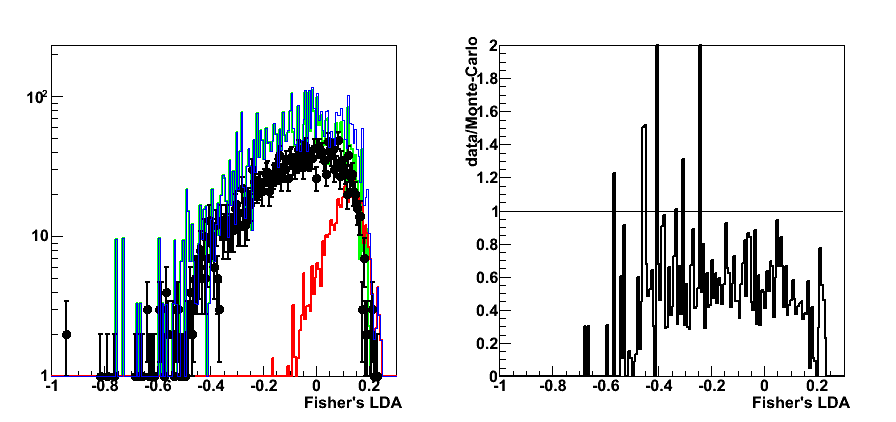

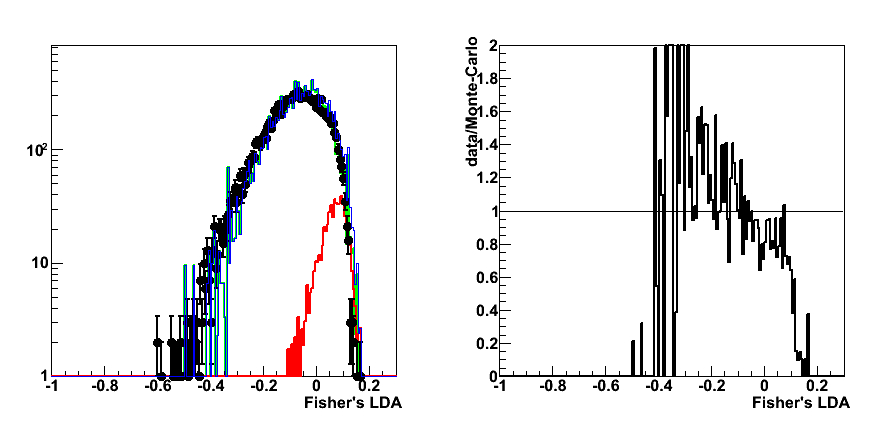

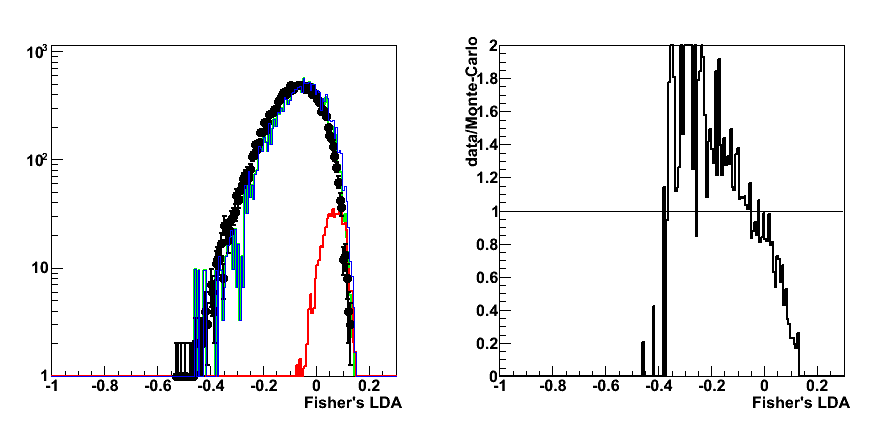

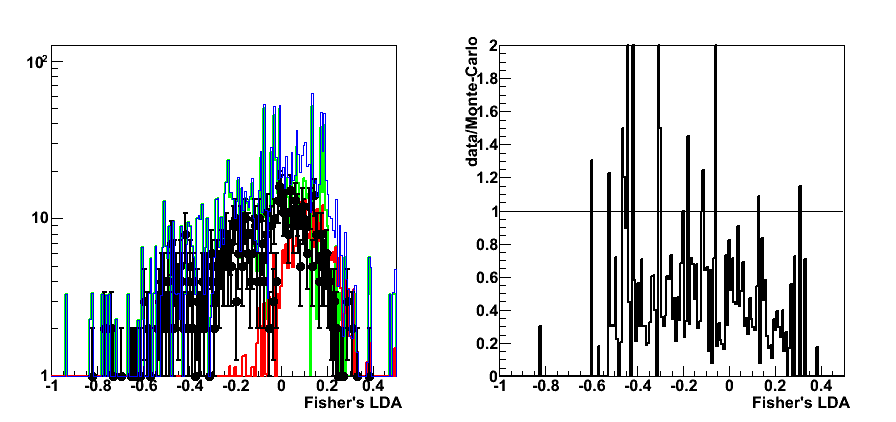

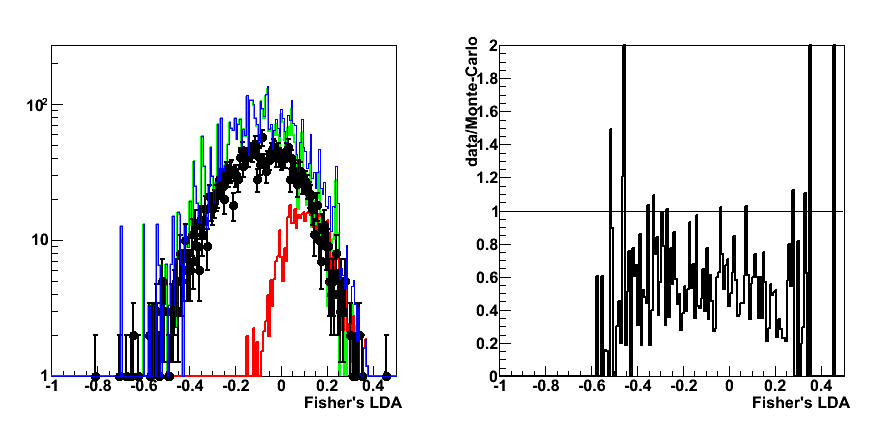

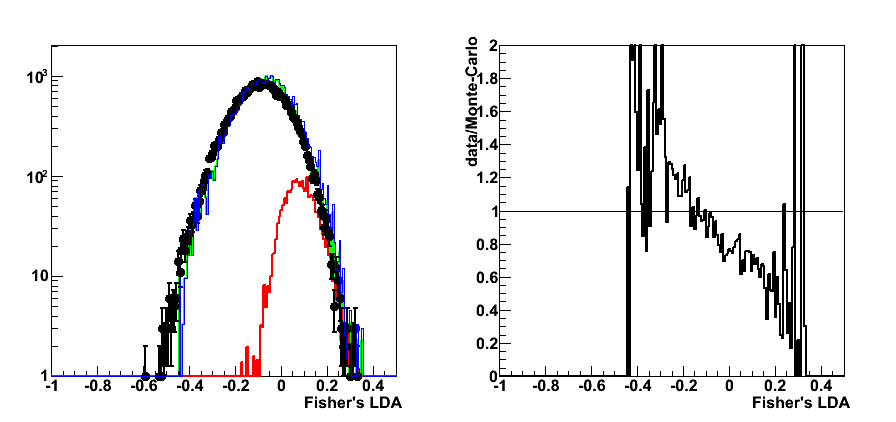

Figure 3: Data to Monte-Carlo comparison for LDA (upper plots) and MLP (lower plots)

Good (within ~ 10%) match between data nad Monte-Carlo

a) up to 0.8 for LDA discriminant, and b) up to -0.7 for MLP.

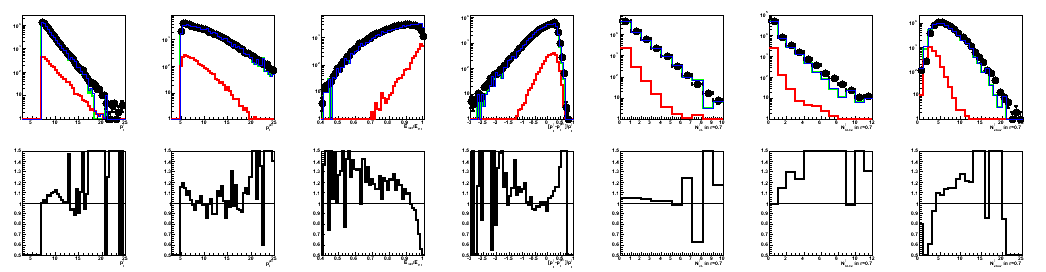

Figure 4: Data to Monte-Carlo comparison for input parameters

from left to right

1) pt_gamma 2) pt_jet 3) r3x3 4) gamma-jet pt balance 5) N_ch[gamma] 6) N_eTow[gamma] 7) N_bTow[gamma]

Colour coding: black pp2006 data, red gamma-jet MC, green QCD MC, blue gamma-jet+QCD

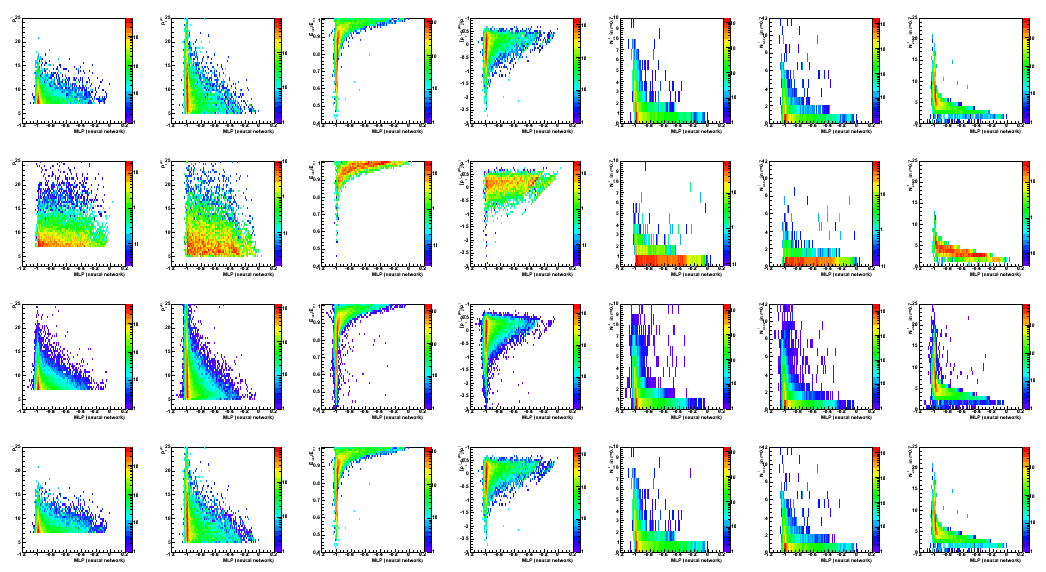

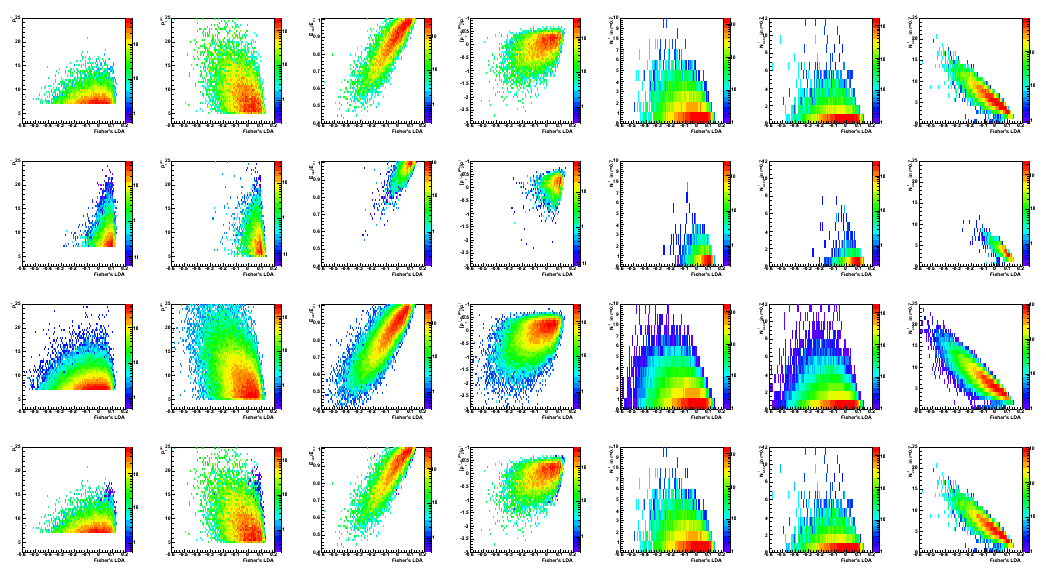

Figure 5: Data to Monte-Carlo comparison:

correlations between input variables (in the same order as in Fig. 4)

and LDA classifier discriminant (horizontal axis).

1st raw: QCD MC; 2nd: gamma-jet MC; 3rd: pp2006 data; 4th: QCD+gamma-jet MC

2009.03.26 Endcap photon-jet update at the STAR Collaboration meeting

Endcap photon-jet update at the STAR Collaboration meeting

04 Apr

April 2009 posts

2009.04.17 WSU nuclear seminar

The STAR spin program with longitudinally polarized proton beams

2009.04.21 Adding SMD info to the LDA

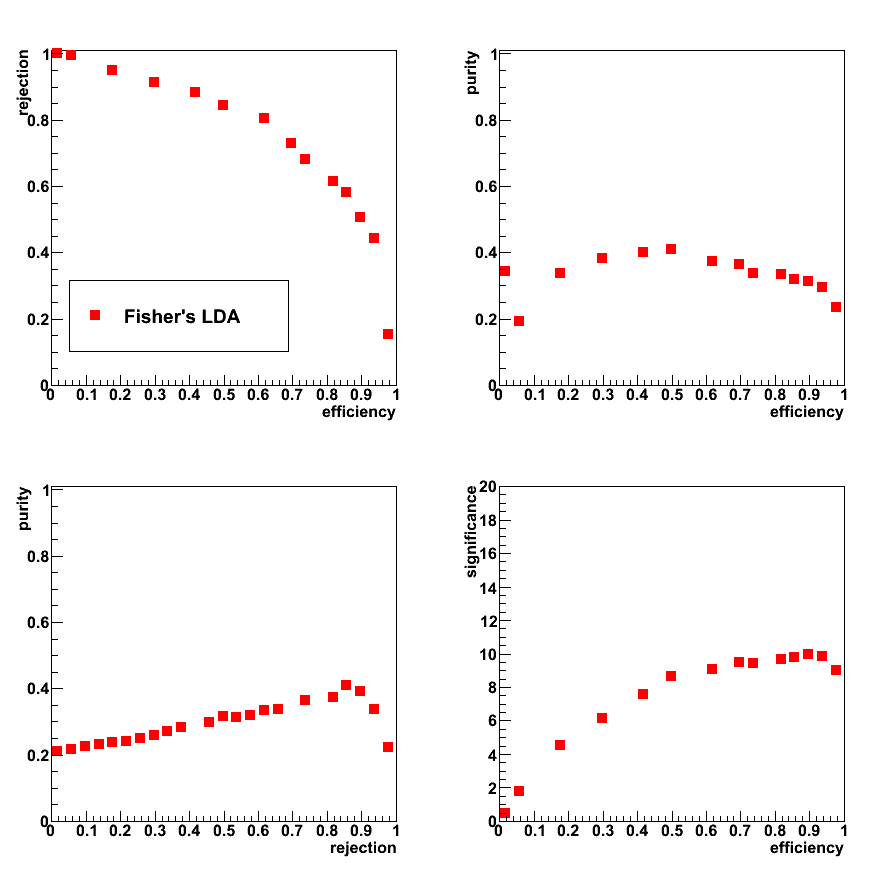

Cut optimization with Fisher's LDA classifier

ROOT implementation for LDA:

Application for cuts optimization in the gamma-jet analysis

LDA configuration: default

LDA input parameters:

- Energy fraction in 3x3 cluster within a r=0.7 radius: r3x3

- Photon-jet pt balance: [pt_gamma-pt_jet]/pt_gamma

- Number of charge tracks within r=0.7 around gamma candidate

- Number of Endcap towers fired within r=0.7 around gamma candidate

- Number of Barrel towers fired within r=0.7 around gamma candidate

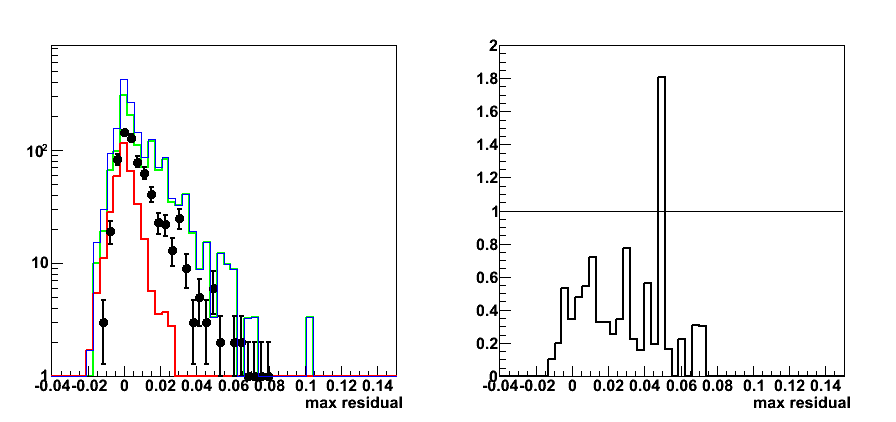

Figure 1: LDA discriminant (no SMD involved in training)

Figure 2: LDA (no SMD): Efficiency, rejection, purity vs. discriminant

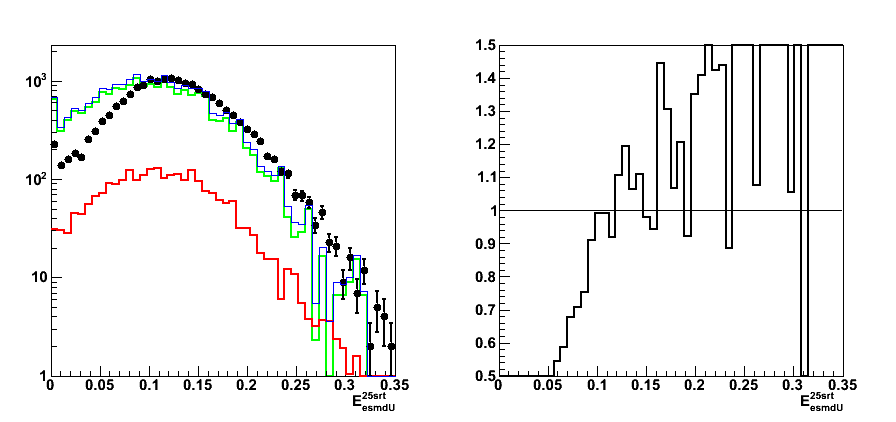

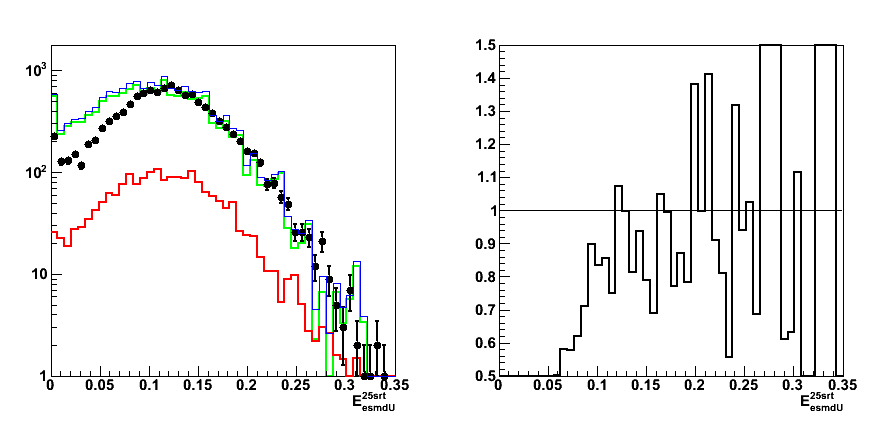

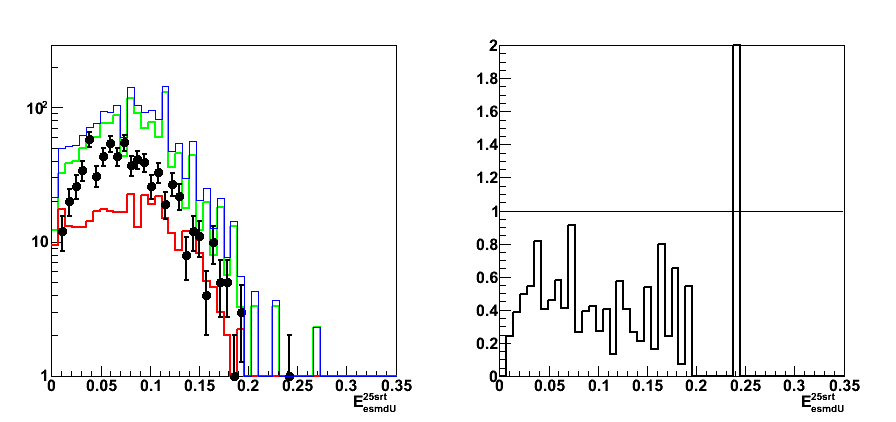

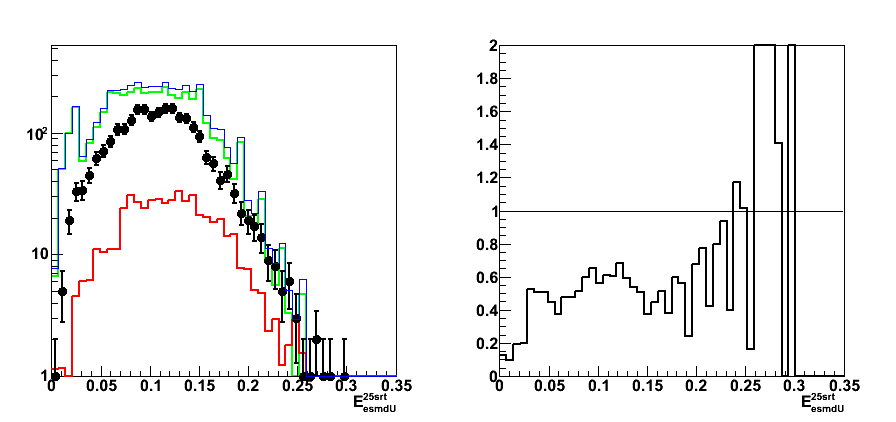

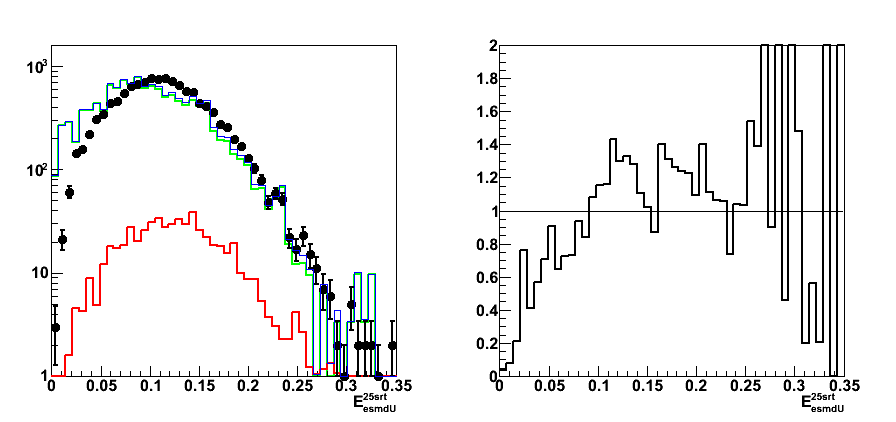

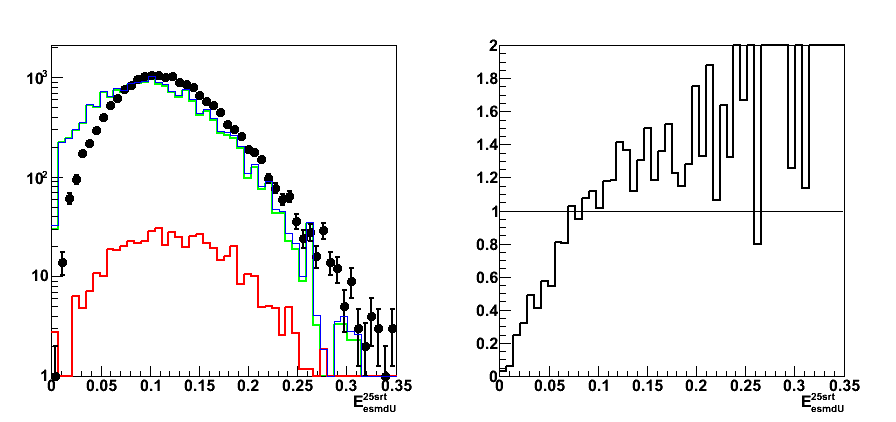

Figure 3: SMD energy in 25 central strips (LDA-dsicriminant>0, no pre-shower1 cut)

Figure 4: SMD energy in 25 central strips (LDA-dsicriminant>0, pre-shower1 < 10MeV)

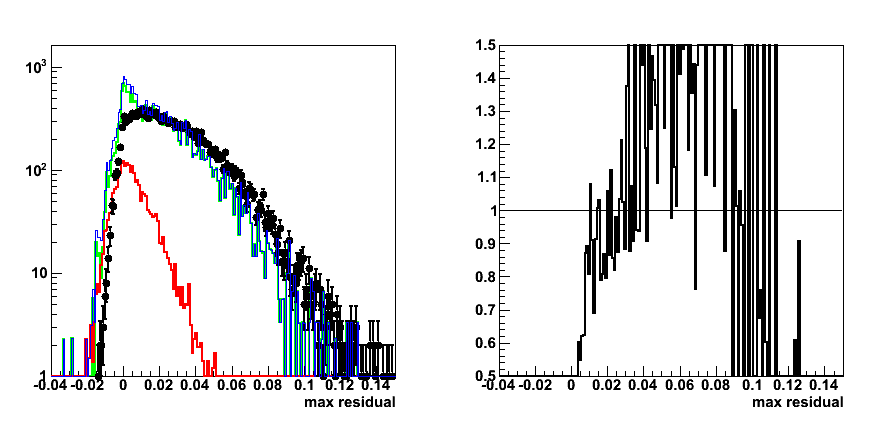

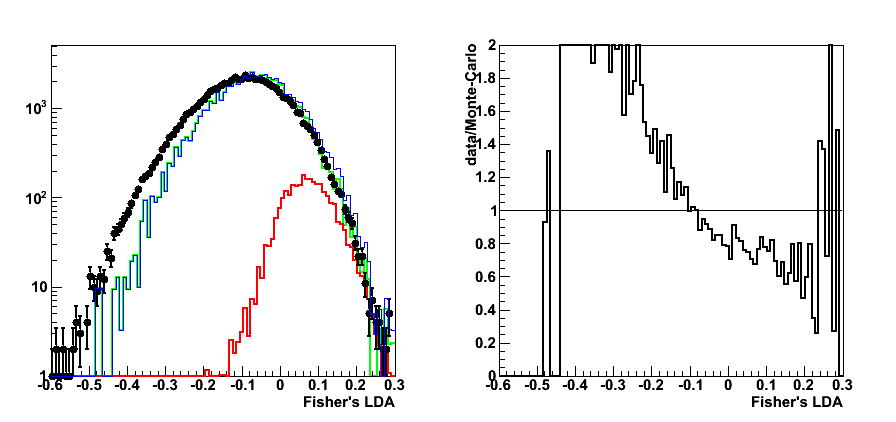

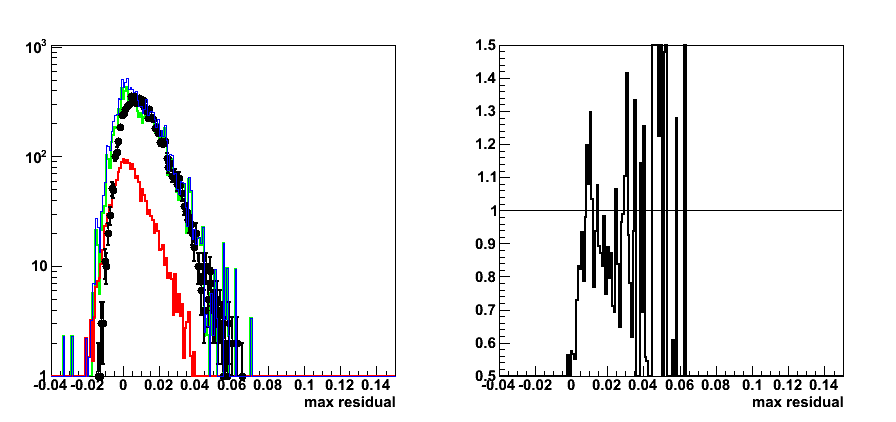

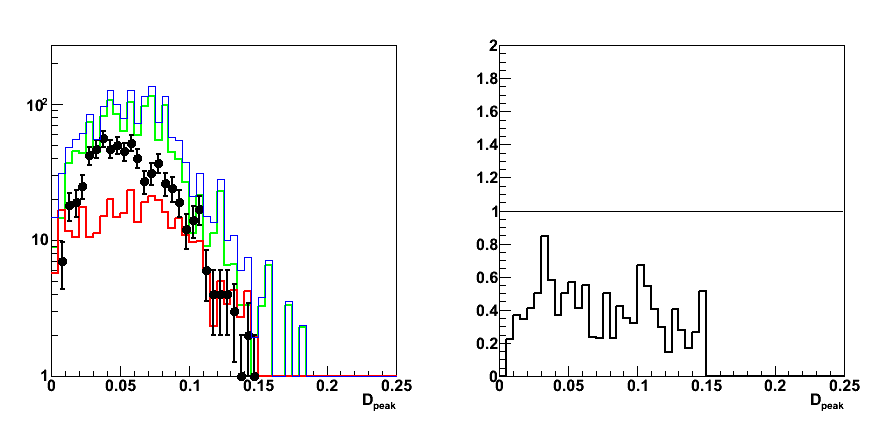

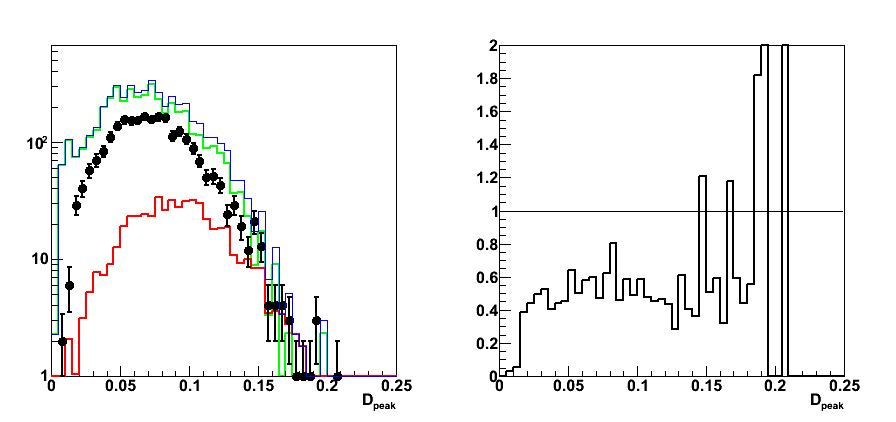

Figure 5: Maximum residual (LDA-dsicriminant>0, no pre-shower1 cut)

Figure 6: Maximum residual (LDA-dsicriminant>0, pre-shower1 < 10MeV)

LDA+ SMD analysis

SMD info added:

a) energy in 5 central srtips

b) maximum sided residual

Figure 7:LDA with SMD: Efficiency, rejection, purity vs. LDA discriminant

Figure 8: LDA discriminant with SMD

Figure 9: Maximum residual (SMD LDA-dsicriminant>0, pre-shower1 < 10MeV)

LDA with and without SMD comparison

Figure 10:LDA (no SMD): Efficiency, rejection, purity plots

Figure 11: LDA with SMD: Efficiency, rejection, purity plots

2009.04.28 LDA plus SMD analysis with pre-shower sorting

Cut optimization with Fisher's LDA classifier

ROOT implementation for LDA:

Application for cuts optimization in the gamma-jet analysis

LDA configuration: default

LDA input parameters (includes SMD inromation of the distance from max sided residual plot):

- Energy fraction in 3x3 cluster within a r=0.7 radius: r3x3

- Photon-jet pt balance: [pt_gamma-pt_jet]/pt_gamma

- Number of charge tracks within r=0.7 around gamma candidate

- Number of Endcap towers fired within r=0.7 around gamma candidate

- Number of Barrel towers fired within r=0.7 around gamma candidate

- Distance to 80% cut line (see this link for more details)

The number of strips in SMD u or v planes is required to be greater than 3

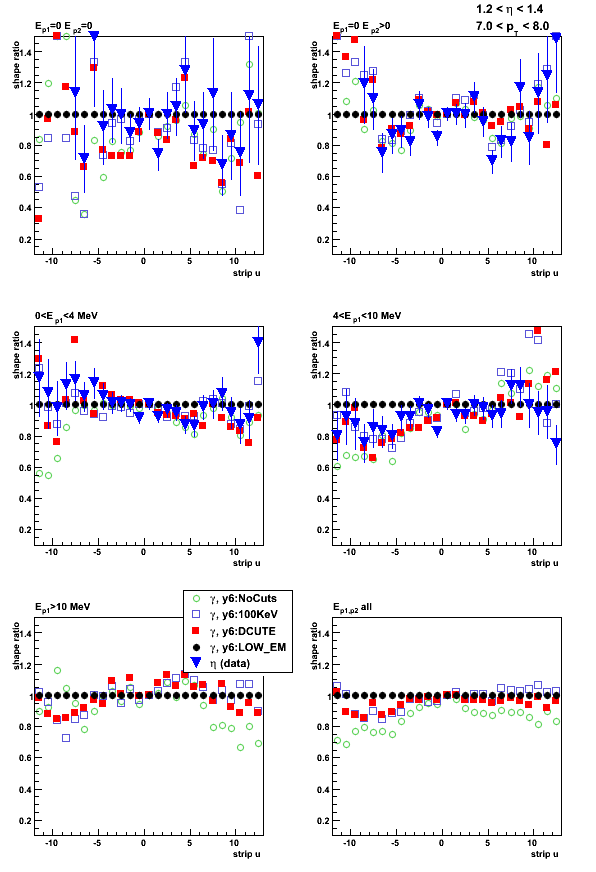

Figure 1: SMD energy in 25 central strips sorted by pre-shower energy

- Upper left: pre1=0, pre2=0

- Upper right: pre1=0, pre2>0

- Lower left: 0<4MeV

- Lower right: 4<10MeV

Right plot for each pre-shower condition shows the ratio of pp2006 data to sum of the Monte-Carlo samples

Colour coding:

black pp2006 data, red gamma-jet MC, green QCD MC, blue gamma-jet+QCD

(combined plot for all pre-shoer bins can be found here)

Figure 2: SMD energy in 5 central strips sorted by pre-shower energy

(combined plot can be found here)

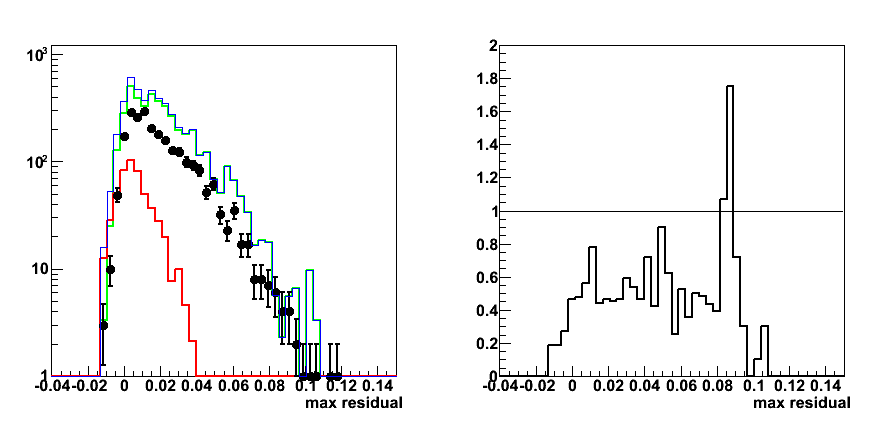

Figure 3: Maximum residual sorted by pre-shower energy

(combined plot can be found here)

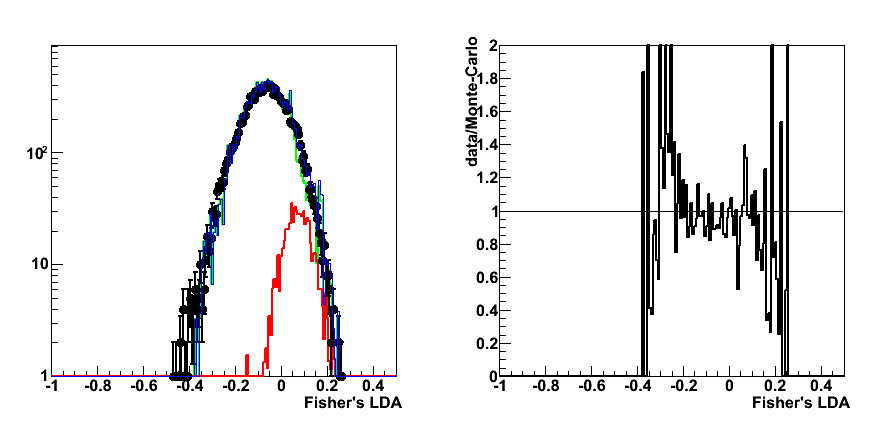

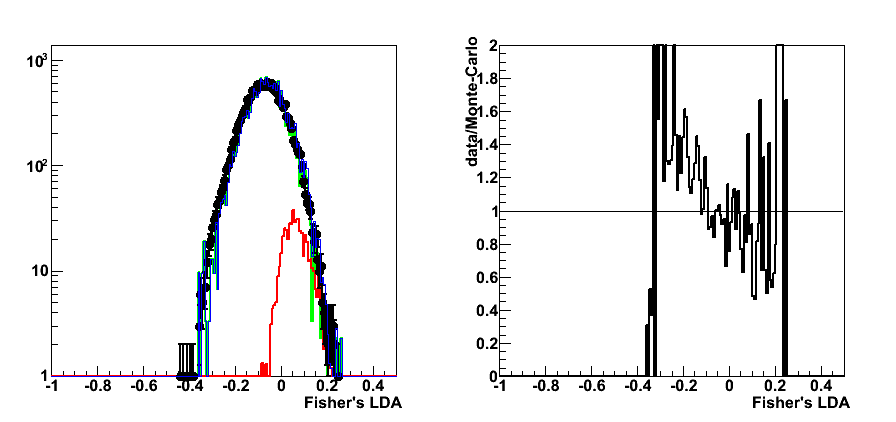

Figure 4: LDA discriminant. Note: LDA algo trained for each pre-shower condition independently

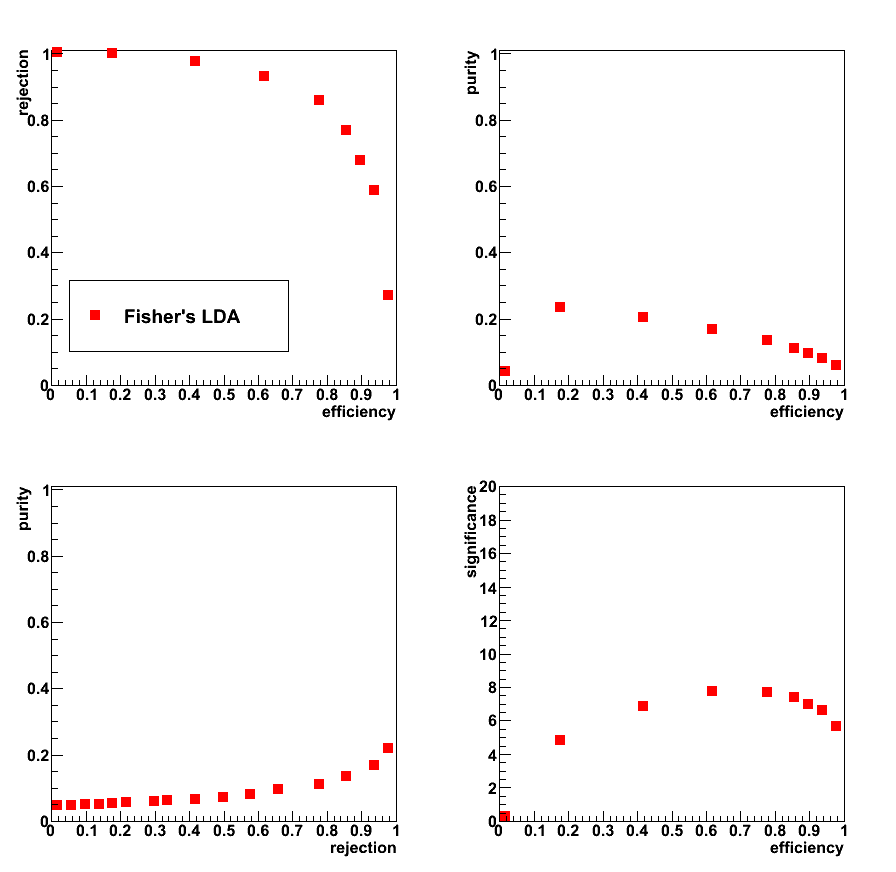

Figure 5: LDA: Efficiency, rejection, purity vs. discriminant, sorted by pre-shower energy

Figure 6: LDA: Efficiency, rejection, purity plots sorted by pre-shower energy

For each pre-shower condition each plot has 4 figures:

- u-left: rejection vs. efficiency

- u-right: purity vs. efficiency

- l-left: purity vs. rejection

- l-right: significance (signal/sqrt{signal+background}) vs. efficiency

05 May

May 2009 posts

2009.05.03 LDA: varying pt and eta cut

Cut optimization with Fisher's LDA classifier

ROOT implementation for LDA:

Application for cuts optimization in the gamma-jet analysis

LDA configuration: default

LDA input parameters Set0:

- Set0:

- Energy fraction in 3x3 cluster within a r=0.7 radius:

E_3x3/E_0.7 - Photon-jet pt balance:

[pt_gamma-pt_jet]/pt_gamma - Number of charge tracks within r=0.7 around gamma candidate:

Ncharge - Number of Endcap towersL fired within r=0.7 around gamma candidate:

NtowBarrel - Number of Barrel towers fired within r=0.7 around gamma candidate

NtowEndcap

- Energy fraction in 3x3 cluster within a r=0.7 radius:

- Set1:

- All from Set0

- Shower shape analysis: distance to 80% cut line:

distance to cut line

- Set2:

- All from Set1

- Energy fraction in E_2x1 and E_2x2 witin E_3x3:

E_2x1/E_2x2 and E_2x2/E_3x3

- Set3:

- All from Set2

- Energy in post-shower layer under 3x3 tower patch:

E_post^3x3

The number of strips in SMD u or v planes is required to be greater than 3

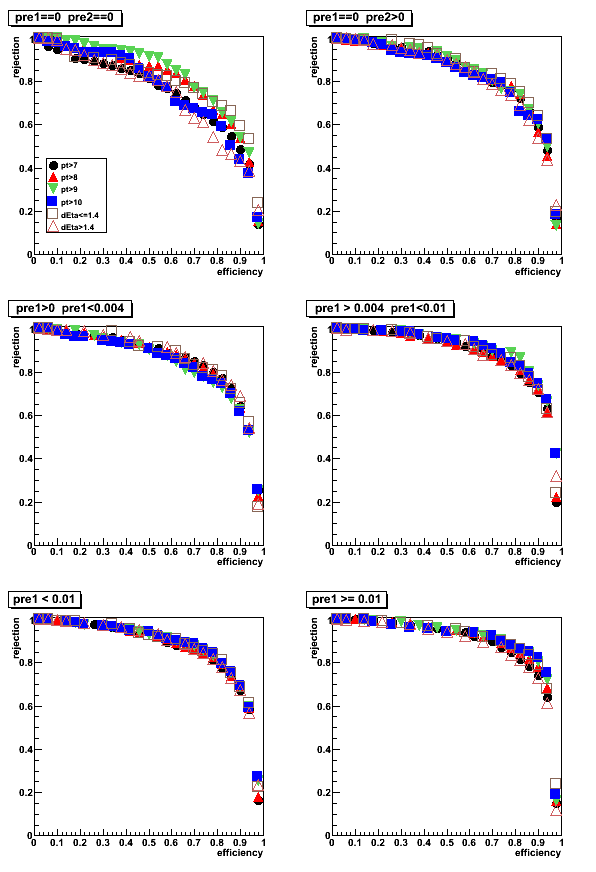

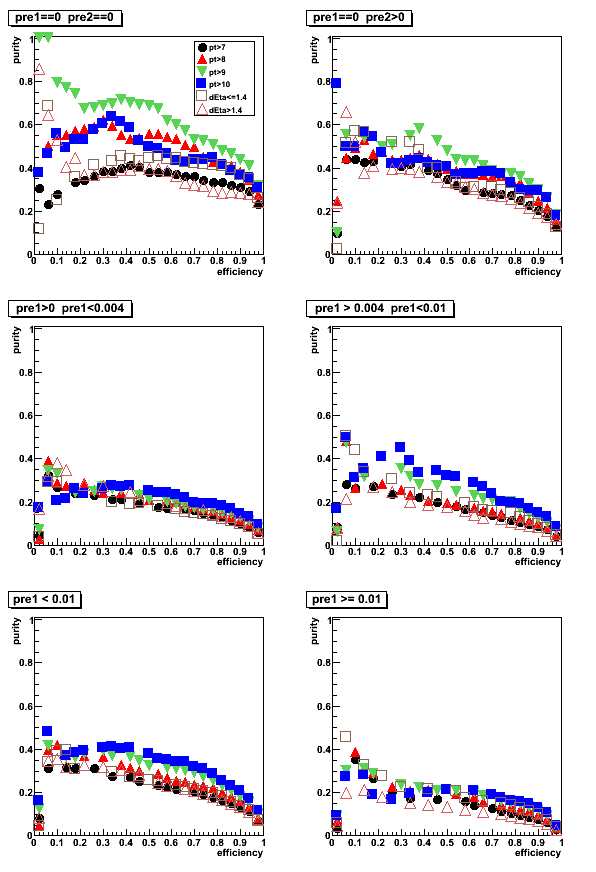

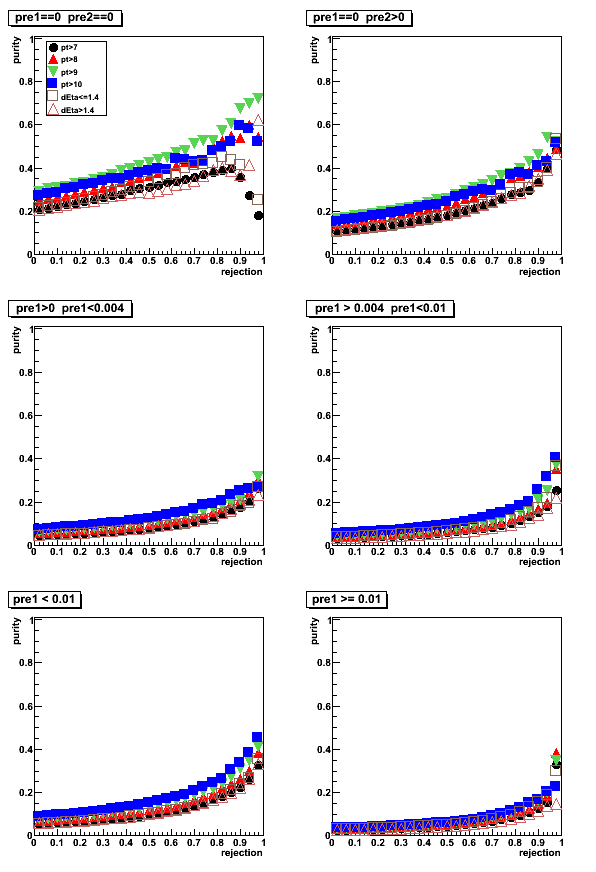

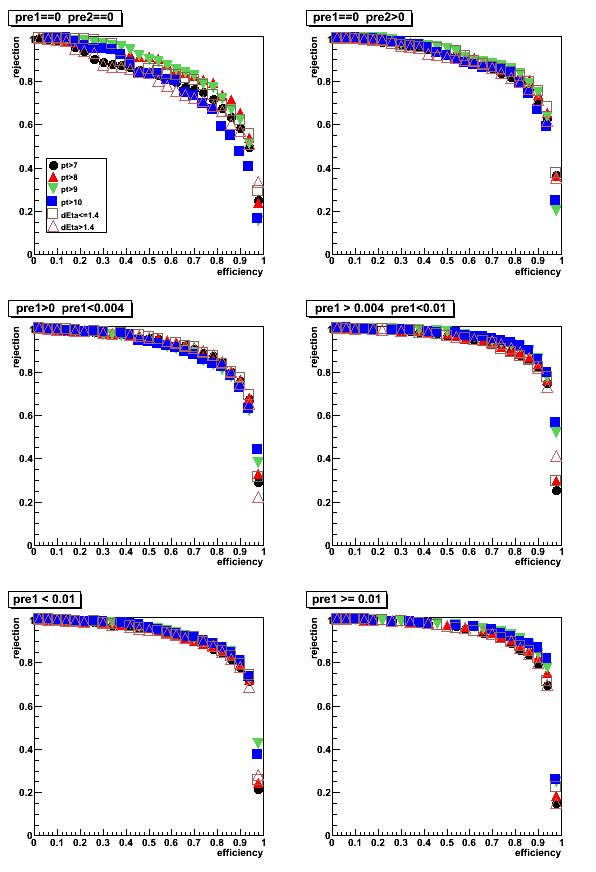

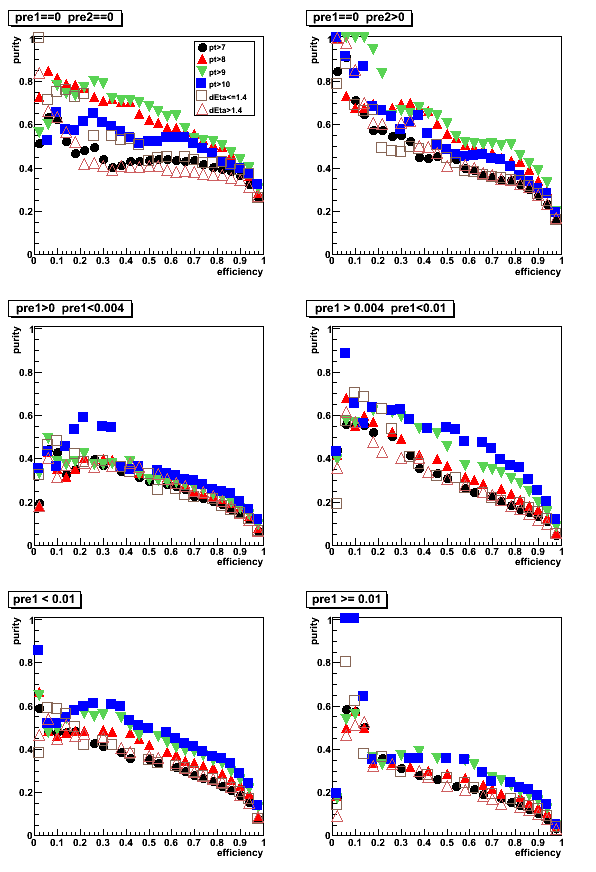

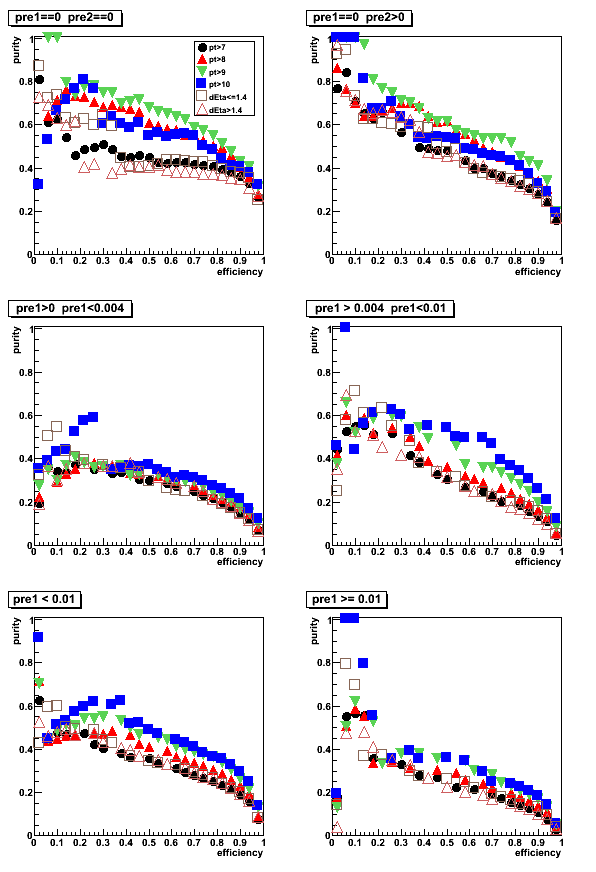

Pre-shower sorting (energy in tiles under 3x3 tower patch):

- pre1=0, pre2=0

- pre1=0, pre2>0

- 0 < pre1 < 0.004

- 0.004 < pre1 < 0.01

- pre1 < 0.01

- pre1 >= 0.01

Photon pt and rapidity cuts:

- pt>7GeV

- pt>8GeV

- pt>9GeV

- pt>10GeV

- detector eta <1.4 (pt>7GeV)

- detector eta > 1.4 (pt>7GeV)

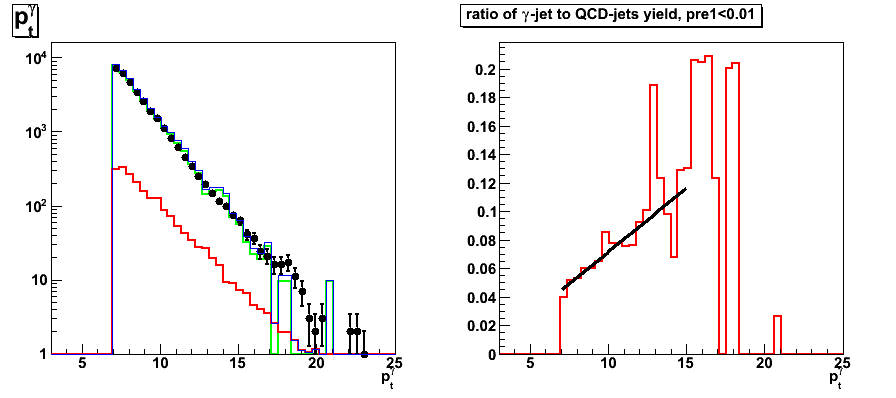

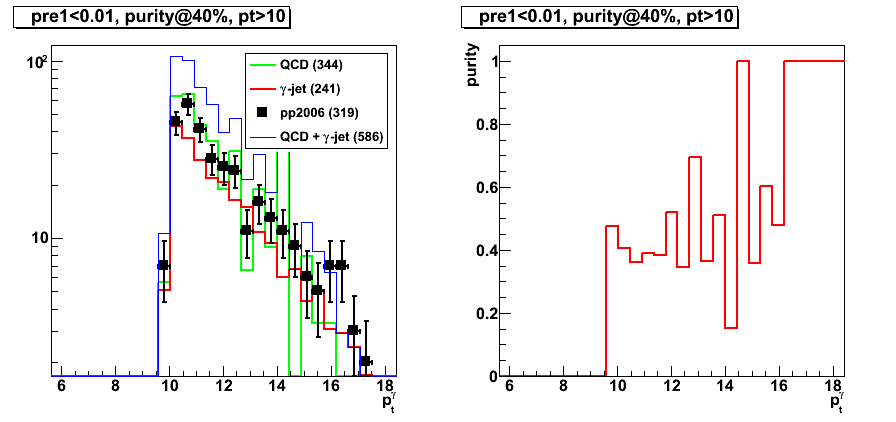

Figure 0: photon pt distribution for pre-shower1<0.01

Colour coding:

black pp2006 data, red gamma-jet MC, green QCD MC, blue gamma-jet+QCD

LDA Set0

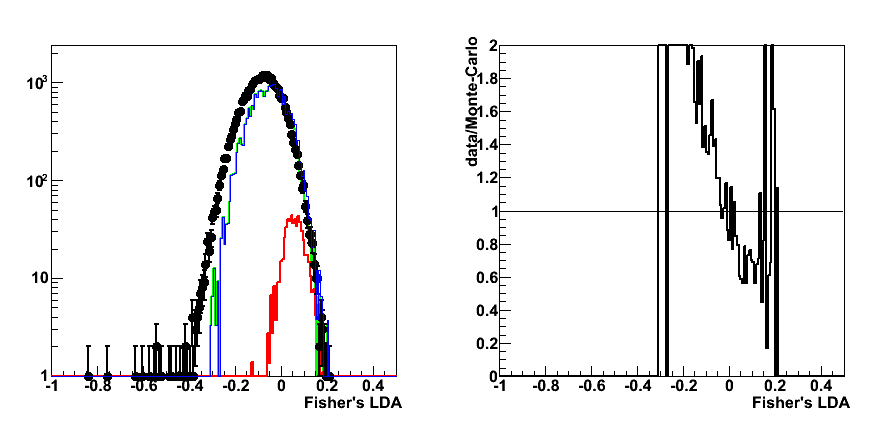

Figure 1: LDA discriminant with Set0: Data to Monte-Carlo comparison (pt>7GeV cut)

Right plot for each pre-shower condition shows the ratio of pp2006 data to sum of the Monte-Carlo samples

Colour coding:

black pp2006 data, red gamma-jet MC, green QCD MC, blue gamma-jet+QCD

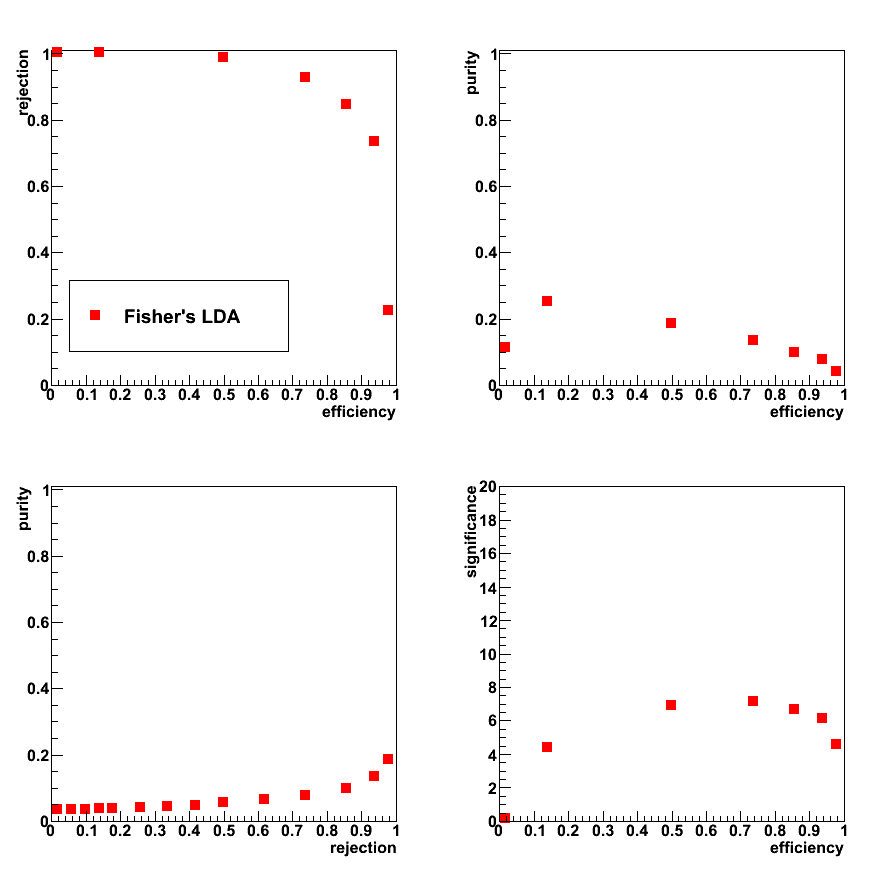

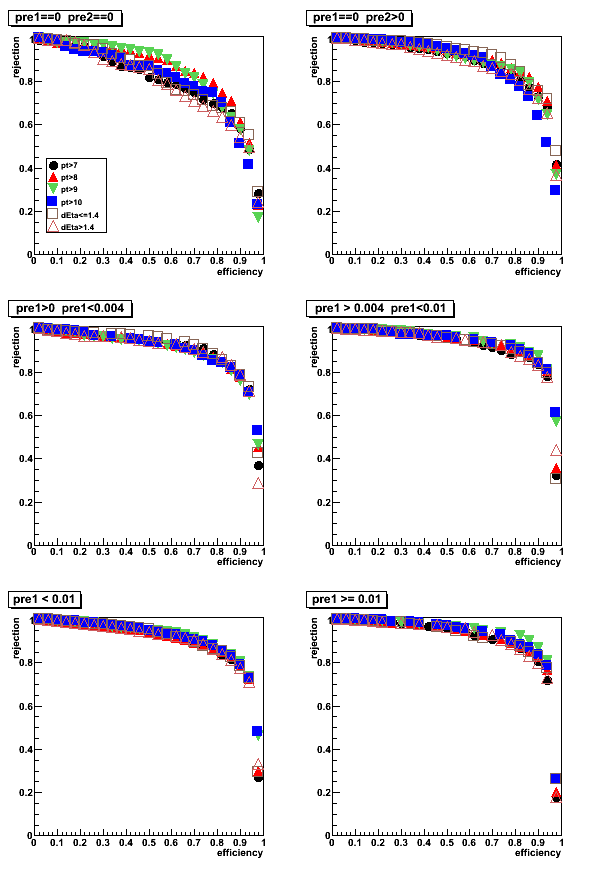

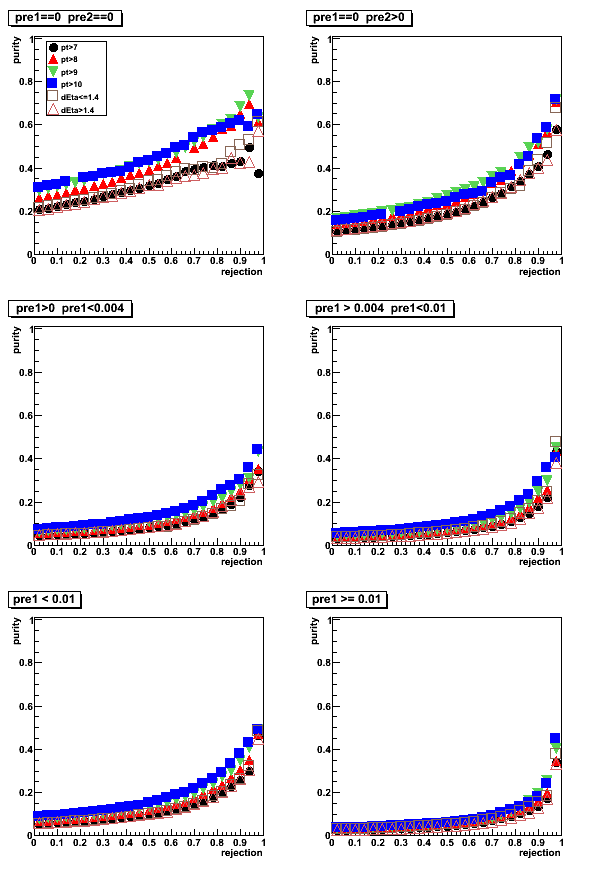

Figure 2: efficiency, purity, rejection vs. LDA discriminant (pt>7GeV cut)

Figure 3: rejection vs. efficiency

Figure 4: purity vs. efficiency

Figure 5: purity vs. rejection

LDA Set1

Figure 6: LDA discriminant with Set1: Data to Monte-Carlo comparison

Figure 7: rejection vs. efficiency

Figure 8: purity vs. efficiency

Figure 9: purity vs. rejection (click link to see the figure)

LDA Set2

Figure 10: rejection vs. efficiency (click link to see the figure)

Figure 11: purity vs. efficiency

Figure 12: purity vs. rejection (click link to see the figure)

LDA Set3

Figure 13: rejection vs. efficiency (click link to see the figure)

Figure 14: purity vs. efficiency

Figure 15: purity vs. rejection (click link to see the figure)

2009.05.04 LDA: More SMD info, 3x3 tower energy, correlation matrix

Cut optimization with Fisher's LDA classifier

ROOT implementation for LDA:

Application for cuts optimization in the gamma-jet analysis

LDA configuration: default

LDA input parameters Set0:

- Set4 (link for results with LDA Set0-Set3):

- Energy fraction in 3x3 cluster within a r=0.7 radius:

E_3x3/E_0.7 - Photon-jet pt balance:

[pt_gamma-pt_jet]/pt_gamma - Number of charge tracks within r=0.7 around gamma candidate:

Ncharge - Number of Endcap towersL fired within r=0.7 around gamma candidate:

NtowBarrel - Number of Barrel towers fired within r=0.7 around gamma candidate

NtowEndcap - Shower shape analysis: distance to 80% cut line:

distance to cut line - Energy fraction in E_2x1 and E_2x2 witin E_3x3:

E_2x1/E_2x2 and E_2x2/E_3x3 - Energy in post-shower layer under 3x3 tower patch:

E_post^3x3 - Tower energy in 3x3 patch:

E_tow^3x3 - SMD-u energy in 25 central strips:

E_smd-u^25 - SMD-v energy in 25 central strips:

E_smd-v^25 - SMD-v peak energy (in 5 central strips):

E_peak

- Energy fraction in 3x3 cluster within a r=0.7 radius:

The number of strips in SMD u or v planes is required to be greater than 3

Pre-shower sorting (energy in tiles under 3x3 tower patch):

- pre1=0, pre2=0

- pre1=0, pre2>0

- 0 < pre1 < 0.004

- 0.004 < pre1 < 0.01

- pre1 < 0.01

- pre1 >= 0.01

Integrated yields per pre-shower bin:

| sample | total integral | pre1=0,pre2=0 | pre1=0, pre2>0 | 0 < pre1 < 0.004 | 0.004 < pre1 < 0.01 | pre1 < 0.01 | pre1 >= 0.01 |

| photon-jet | 2.5640e+03 | 3.5034e+02 | 5.2041e+02 | 5.6741e+02 | 5.2619e+02 | 1.9644e+03 | 5.9994e+02 |

| QCD | 5.6345e+04 | 1.3515e+03 | 4.3010e+03 | 1.2289e+04 | 1.5759e+04 | 3.3701e+04 | 2.2644e+04 |

| pp2006 | 6.2811e+04 | 6.8000e+02 | 2.4310e+03 | 1.2195e+04 | 1.6766e+04 | 3.2072e+04 | 3.0739e+04 |

Photon pt and rapidity cuts:

- pt>7GeV

- pt>8GeV

- pt>9GeV

- pt>10GeV

- detector eta <1.4 (pt>7GeV)

- detector eta > 1.4 (pt>7GeV)

LDA Set4

Figure 1: LDA discriminant with Set0: Data to Monte-Carlo comparison (pt>7GeV cut)

Right plot for each pre-shower condition shows the ratio of pp2006 data to sum of the Monte-Carlo samples

Colour coding:

black pp2006 data, red gamma-jet MC, green QCD MC, blue gamma-jet+QCD

Figure 2: rejection vs. efficiency

Figure 3: purity vs. efficiency

Figure 4: purity vs. rejection

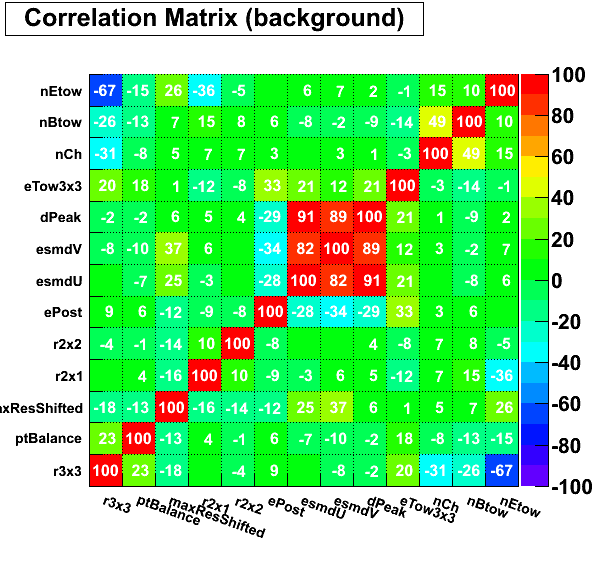

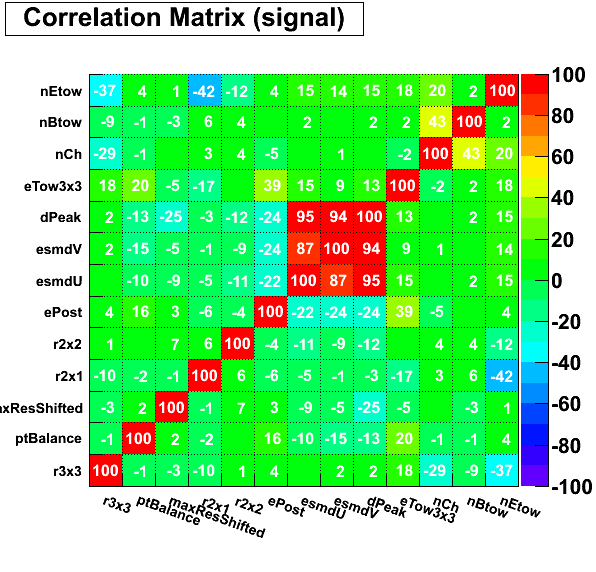

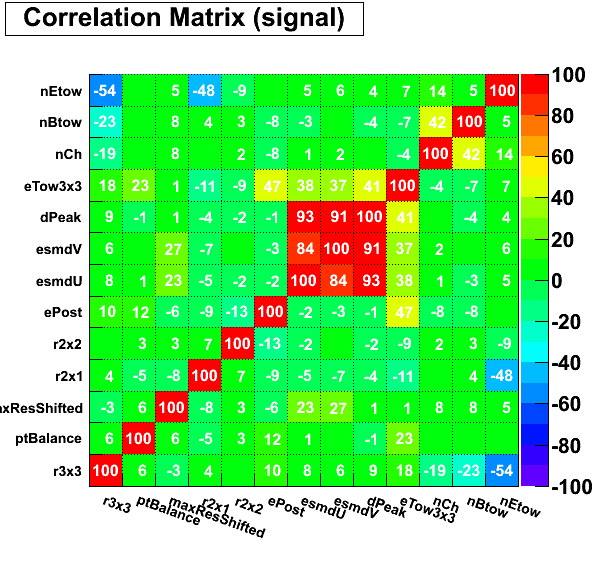

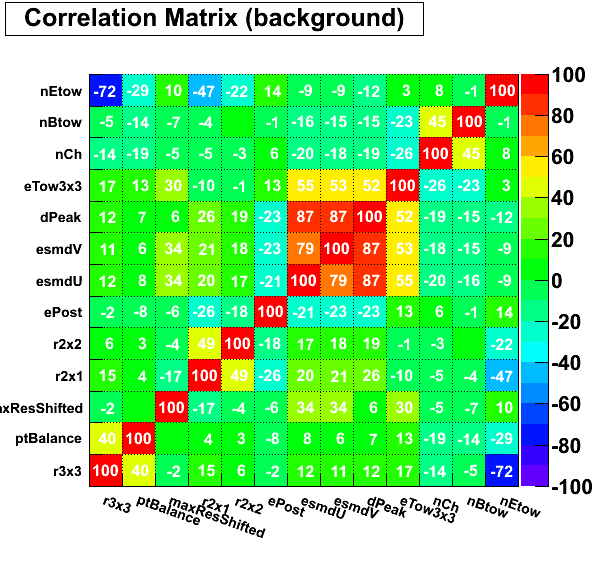

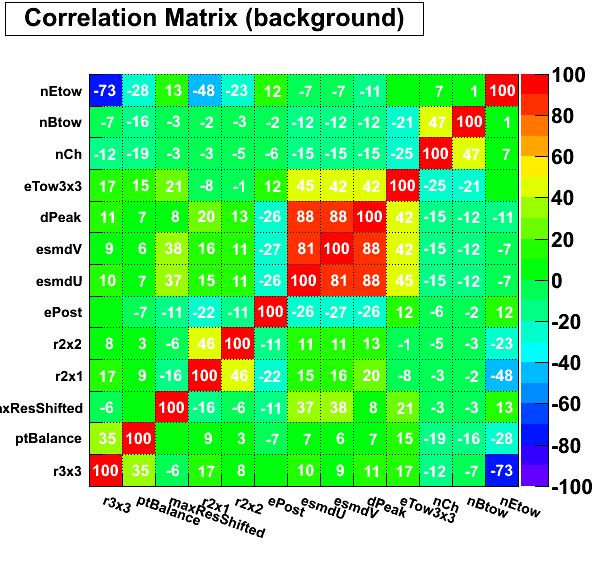

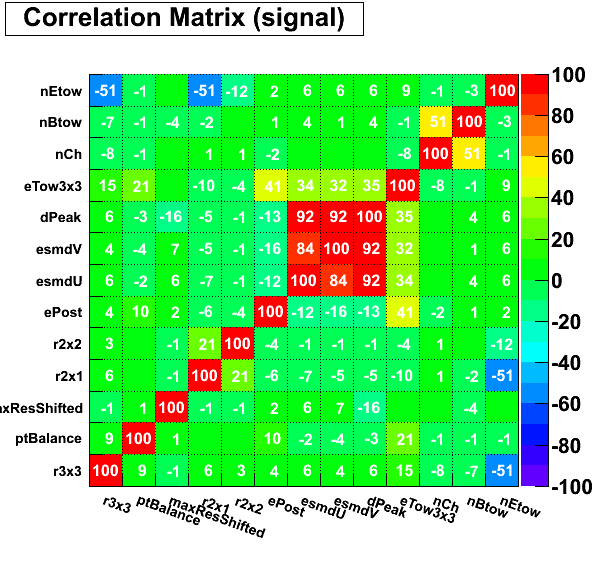

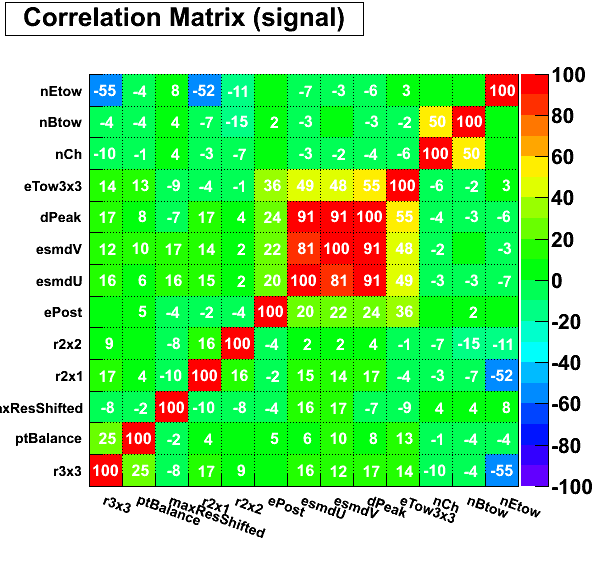

Figure 5: Correlation matrix (pt>7GeV cut)

pre1=0, pre2=0

pre1=0, pre2>0

0 < pre1 < 0.004

0.004 < pre1 < 0.01

pre1 < 0.01

pre1 >= 0.01

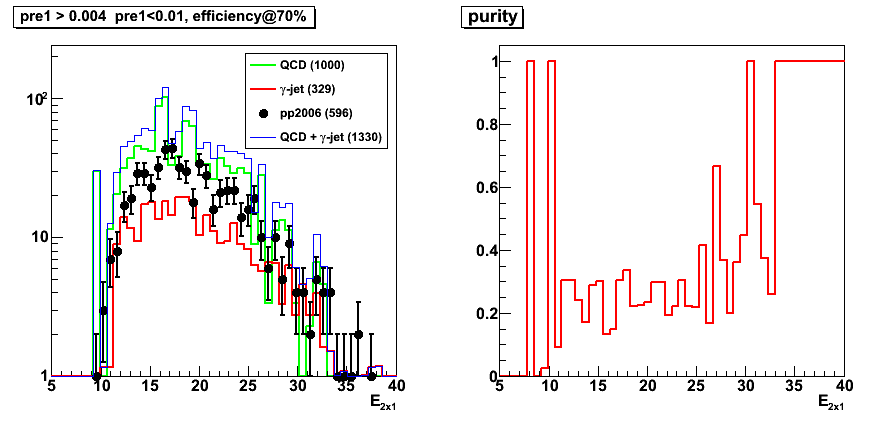

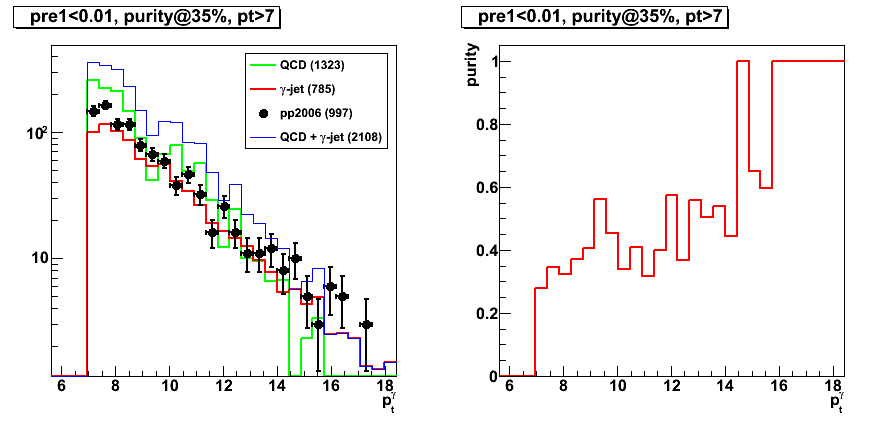

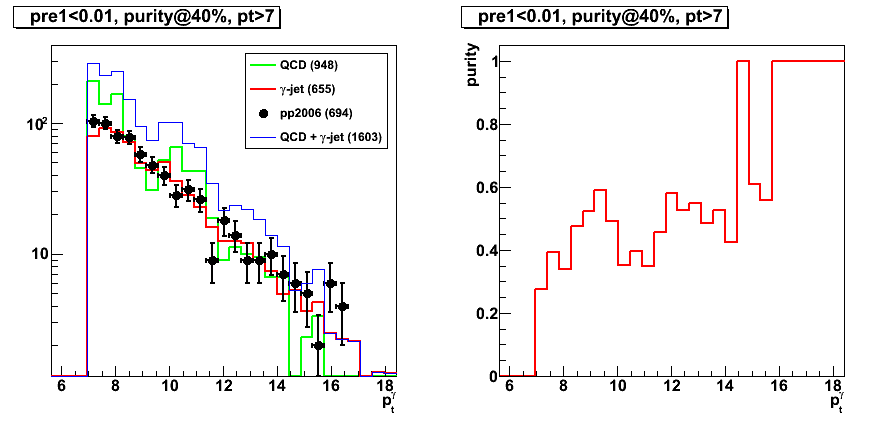

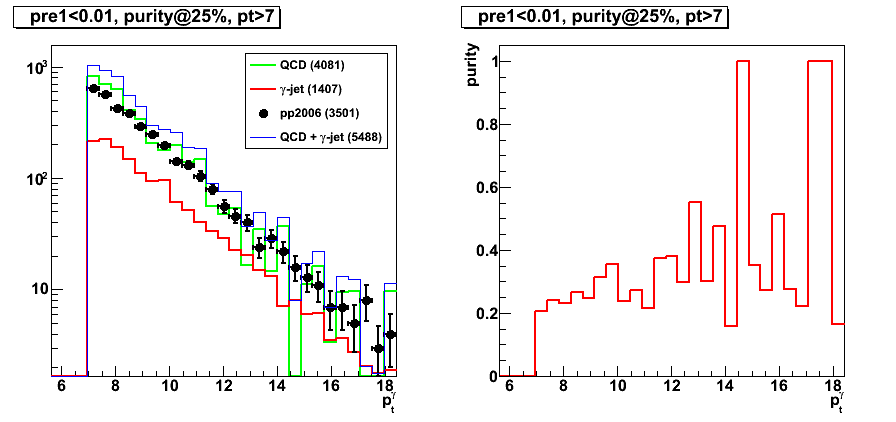

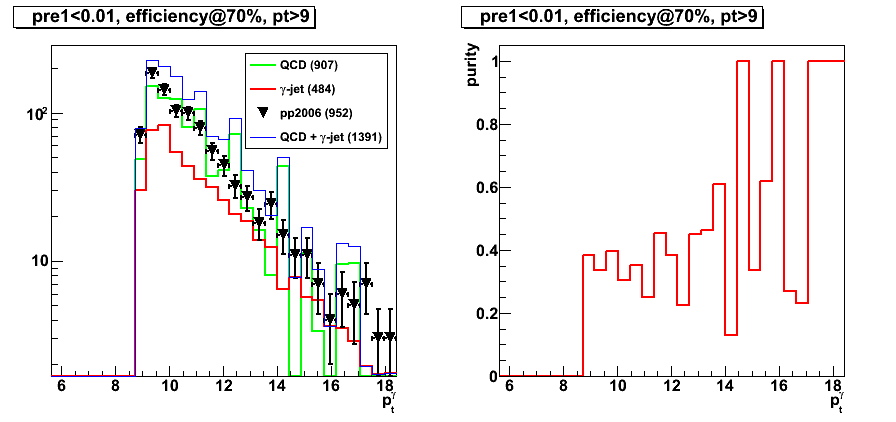

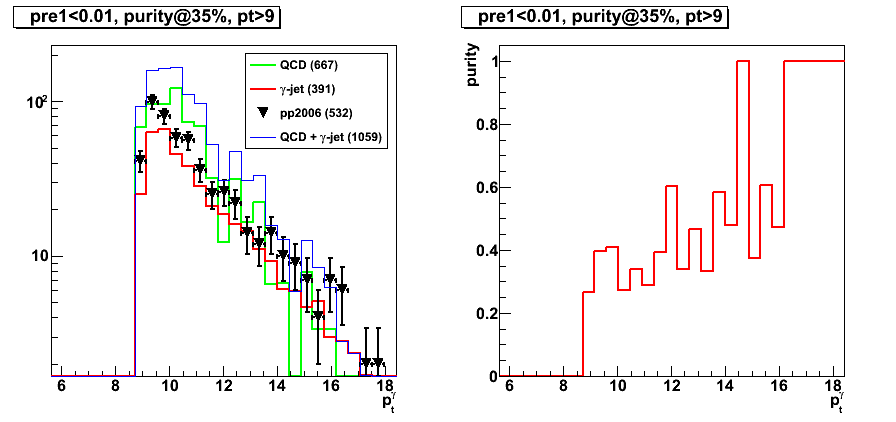

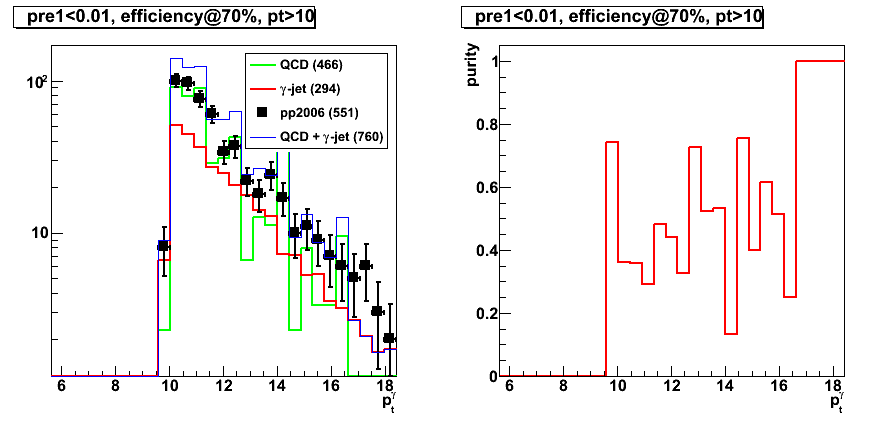

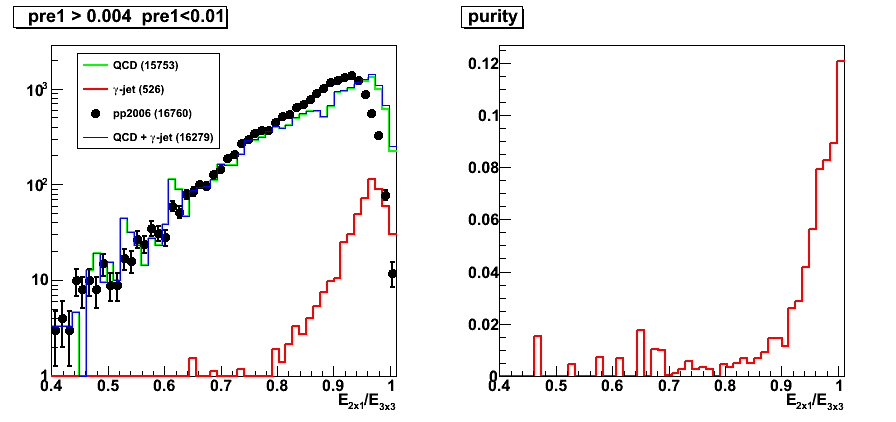

2009.05.06 Applying cuts on LDA: request minimum purity or efficiency

Cut optimization with Fisher's LDA classifier

For this post LDA input parameters Set4 has been used

LDA for various pre-shower bins is trained independetly,

and later results with pre-shower1<0.01 are combined.

There are a set of plots for various photon pt cuts (pt> 7, 8, 9 10 GeV)

and with different selection of cutoff for LDA

(either based on purity or efficiency).

Number in brackets shows the total yield for the sample.

Link to all plots (16 total) as a single pdf file

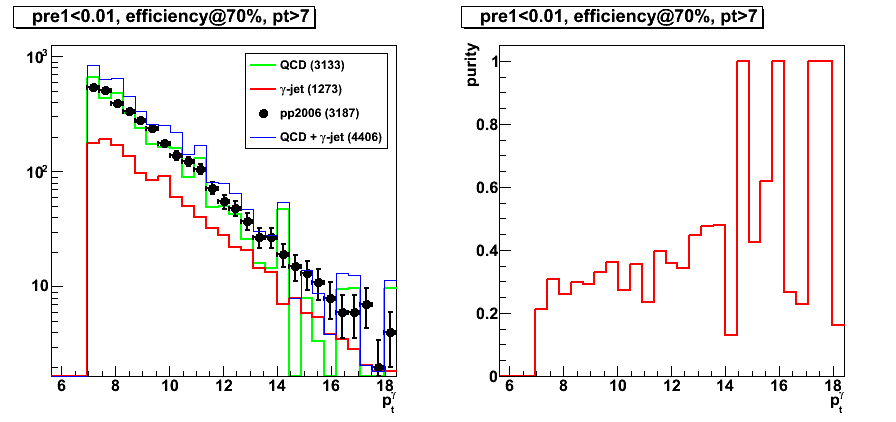

pt > 7GeV

Figure 1: pt > 7GeV, efficiency@70

Figure 2: pt > 7GeV, purity@35

Figure 3: pt > 7GeV, purity@40

Figure 4: pt > 7GeV, purity@25 (Note: very similar to results with efficiency@70)

pt > 9GeV

Figure 5: pt > 9GeV, efficiency@70

Figure 6: pt > 9GeV, purity@35

pt > 10GeV

Figure 7: pt > 10GeV, efficiency@70

Figure 8: pt > 10GeV, purity@40

2009.05.07 Photon-jets analysis with the Endcap Calorimeter

Photon-jets with the Endcap Calorimeter

(analysis status update for Spin PWG)

Slides in pdf format:

2009.05.12 Variable distributions after LDA at 70% efficiency

Cut optimization with Fisher's LDA classifier

For this post LDA results with Set1 and Set2 has been used

Note, that LDA for various pre-shower bins is trained independetly

pdf-links with results for pre1=0 and pre2=0 (pre-shower bin 1):

- before LDA cut (figures are not sorted)

- after LDA cut @70% efficiency for Set 2 (figures are not sorted)

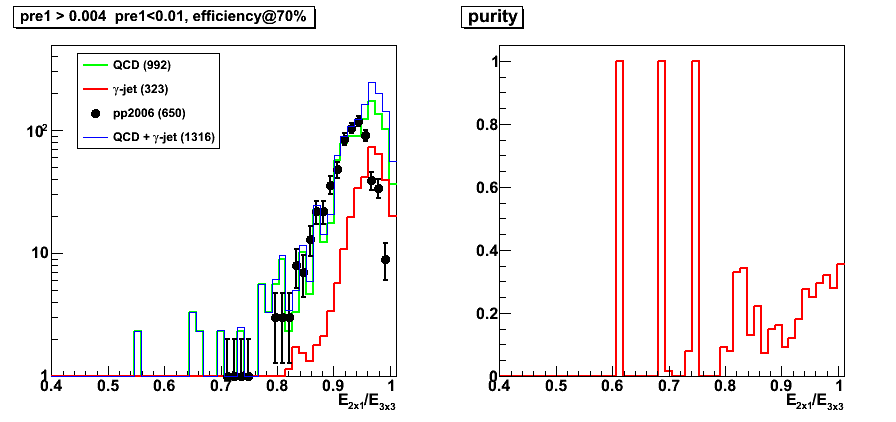

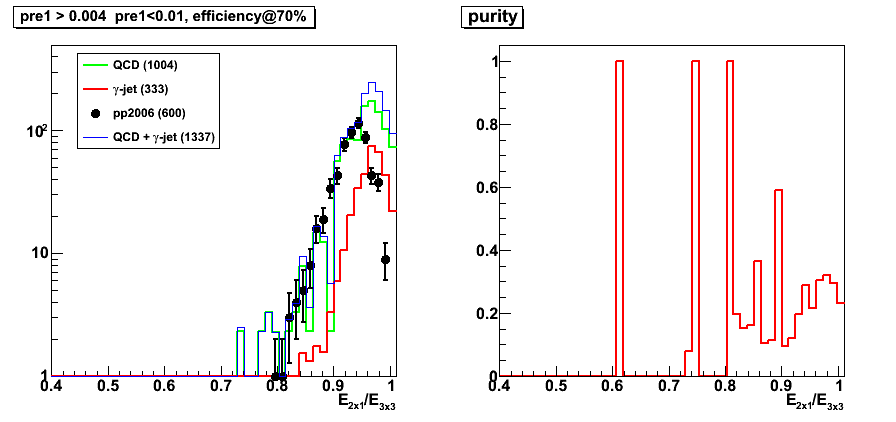

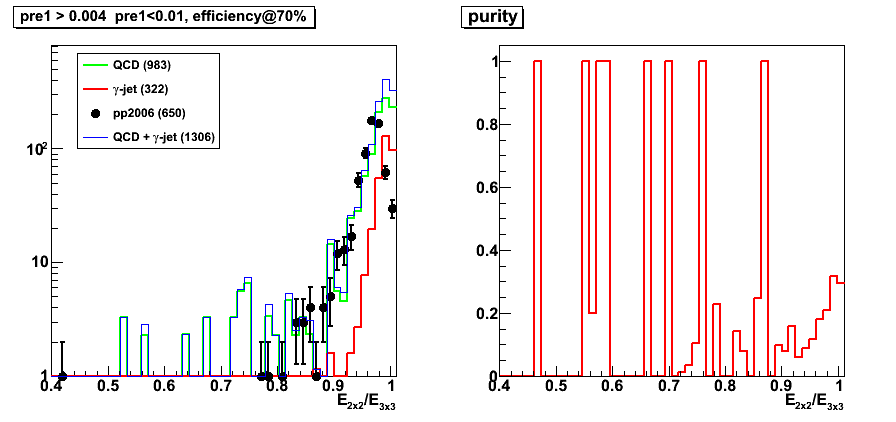

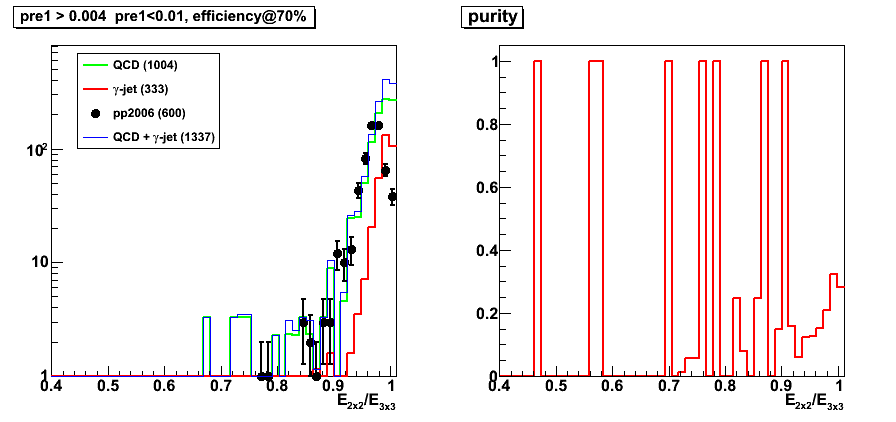

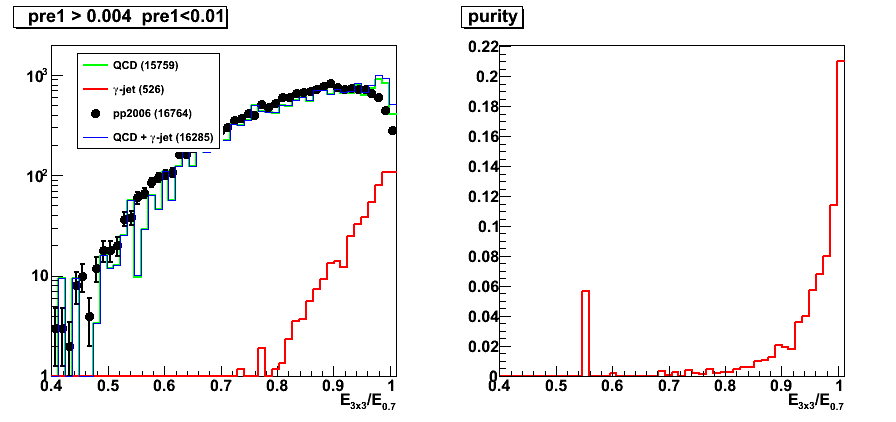

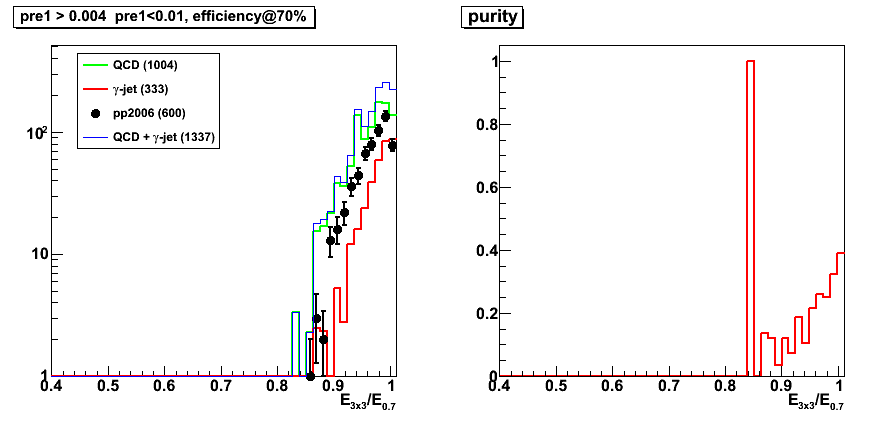

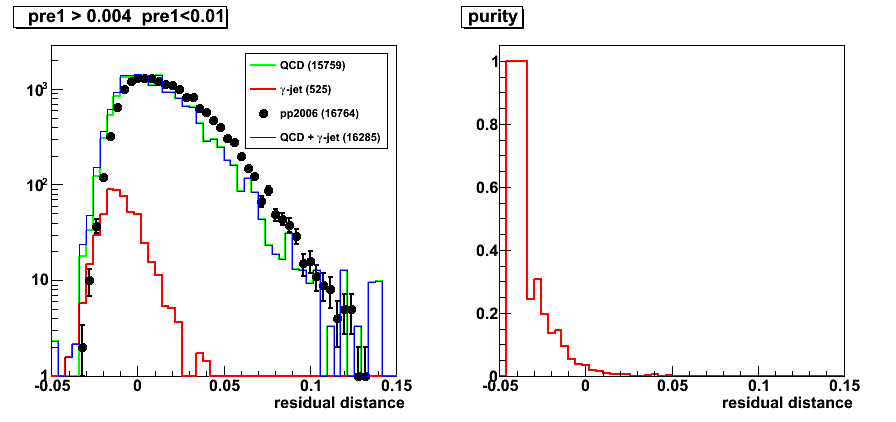

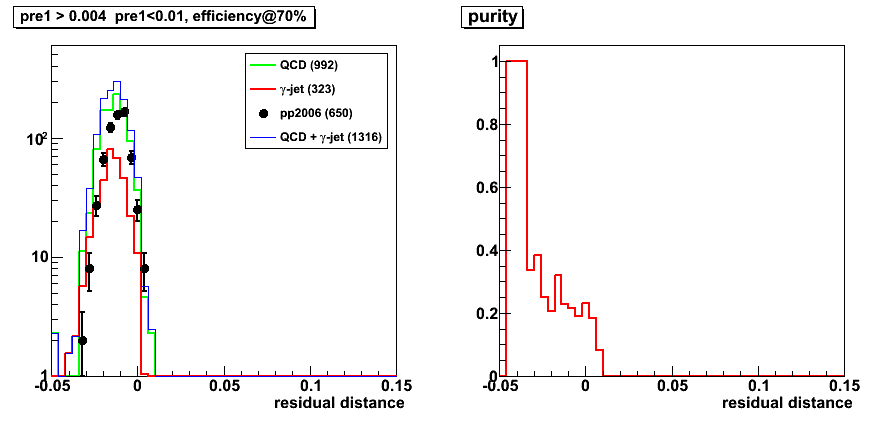

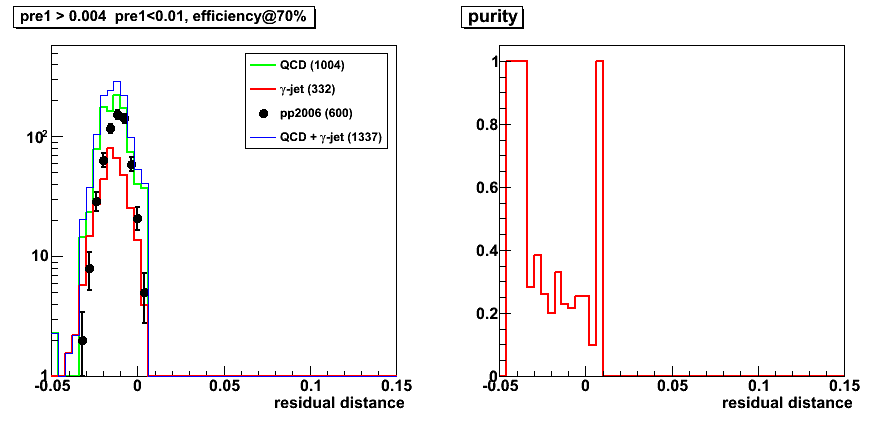

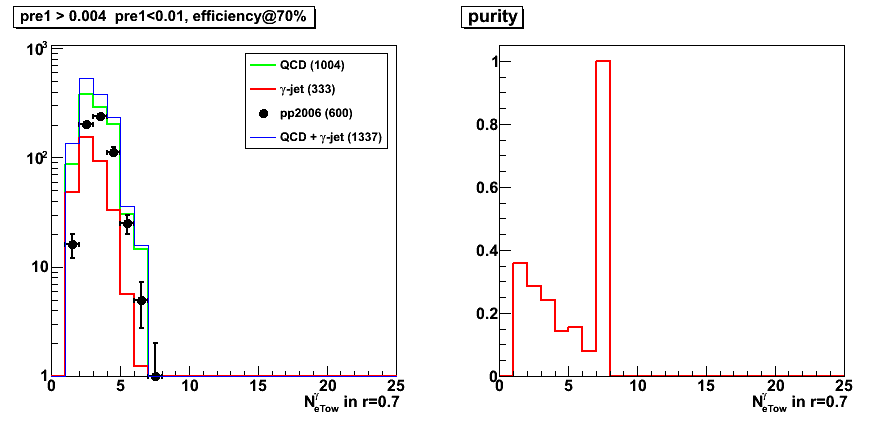

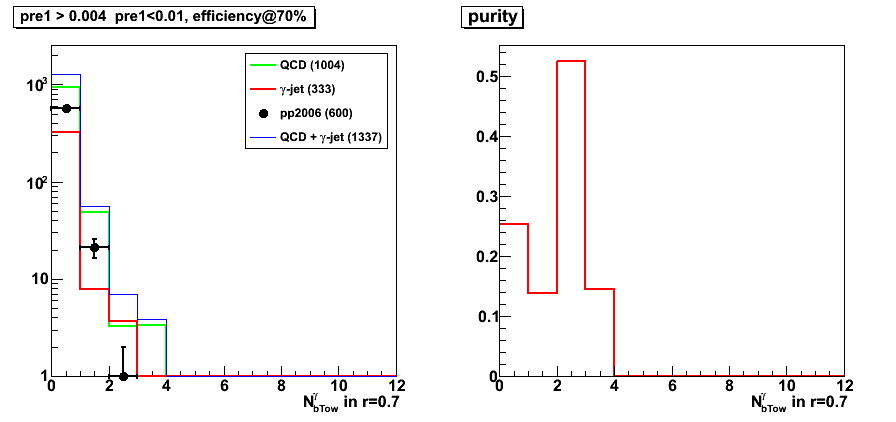

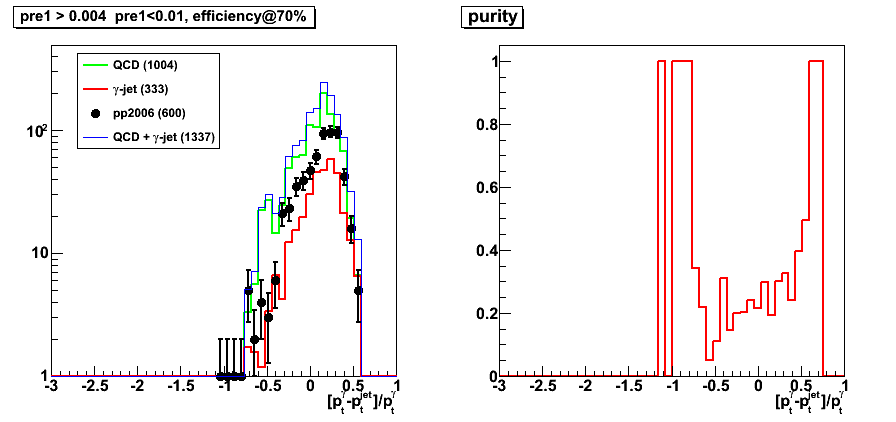

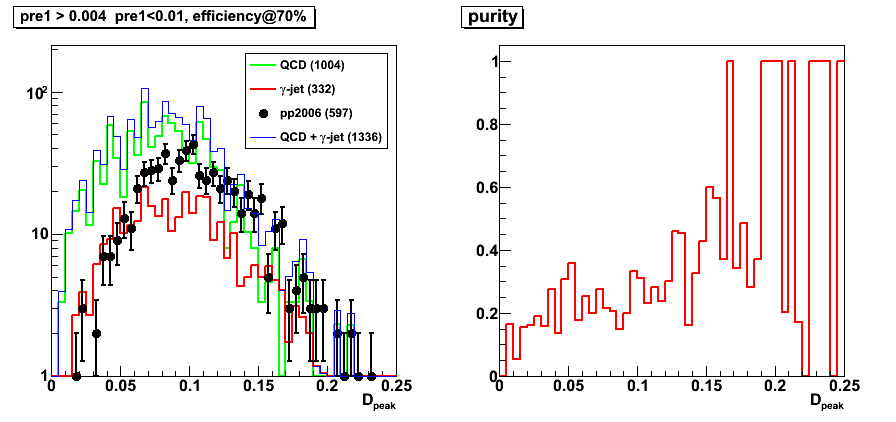

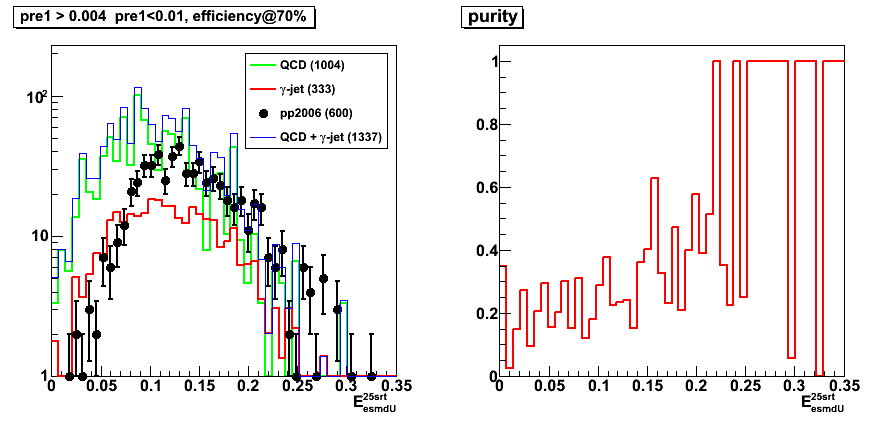

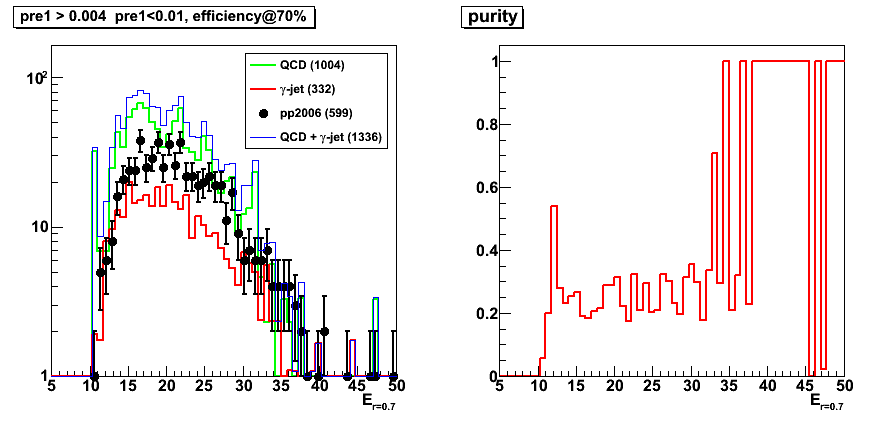

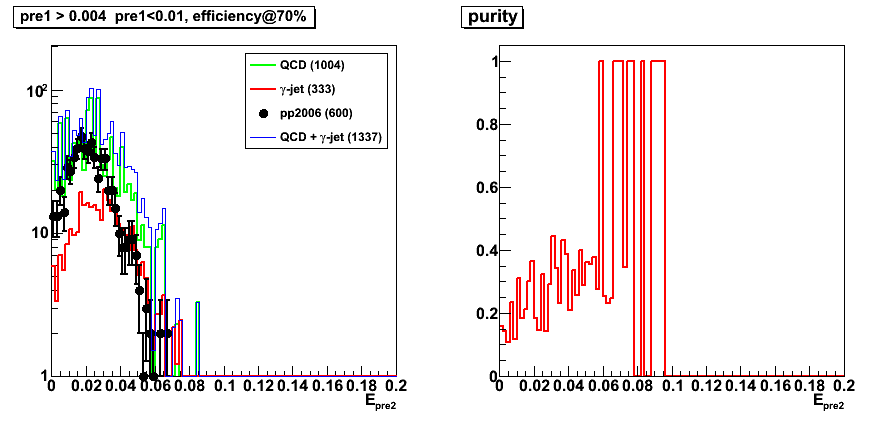

Figures below are for 0.004<pre-shower1<0.01 (pre-shower bin 4).

Photon pt cut: pt> 7, pre-shower bin: 0.004 < pre1 < 0.01

LDA cut with efficiency @ 70%

Set1 vs. Set2

What is added in Set2 compared to Set1:

smaller cluster size information (r2x1, r2x2), post-shower energy

Figure 1: r2x1

before LDA cut

LDA cut for Set1

LDA cut for Set2

Figure 2: r2x2

before LDA cut

LDA cut for Set1

LDA cut for Set2

Figure 3: r3x3

before LDA cut

LDA cut for Set1

LDA cut for Set2

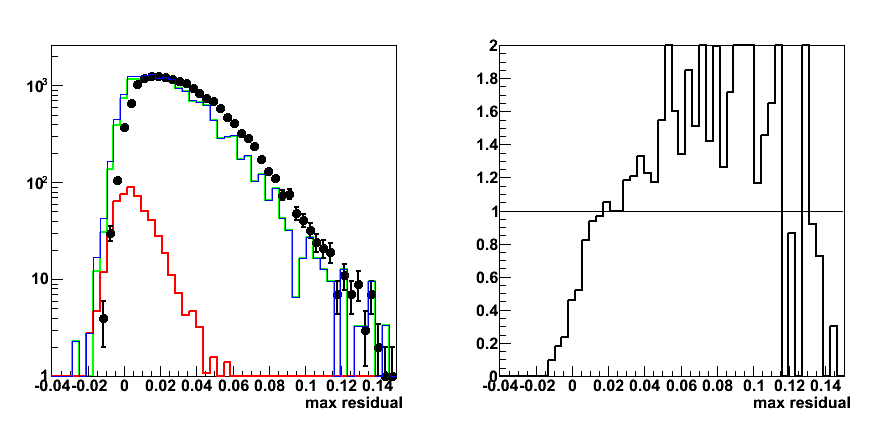

Figure 4: Residual distance

before LDA cut

LDA cut for Set1

LDA cut for Set2

Other variables with LDA Set2 cut

Note: Only plos for LDA cut @70 efficiency for Set2 are shown

Figure : number of charge particles around photon

Figure 5: number of EEMC tower around photon

Figure 6: number of BEMC tower around photon

Figure 7: photon-jet pt balance

Figure 8: SMD energy in 5 centrapl strips

Figure 9: SMD energy in 25 central strips: u and v plane separately (plot for V plane)

Figure 13: tower energy in r=0.7 radius

Figure 14: 3x3 pre-shower1 energy

Figure 15: 3x3 pre-shower2 energy

Figure 16: 3x3 post-shower energy

2009.05.31 CIPANP 2009 photon-jet presentation

CIPANP 2009 presentation on photon-jet study

Title:

"Photon-jet coincidence measurements

in polarized pp collisions at sqrt{s}=200GeV

with the STAR Endcap Calorimeter"

- Presentation in pdf format

- Older versions: 0, 1, 2 3, 4, 5, open office file: odp

- Submitted abstract

- Conference link: CIPANP 2009

06 Jun

June 2009 posts

2009.06.22 CIPANP 2009 photon-jet proceedings

CIPANP 2009 proceedings on photon-jet study

Title:

"Photon-jet coincidence measurements

in polarized pp collisions at sqrt{s}=200 GeV

with the STAR Endcap Calorimeter"

- Proceedings: latest version

Older versions: 01 02 03 04 05 - Presentation

- Submitted abstract

- Conference link: CIPANP 2009

07 Jul

July 2009 posts

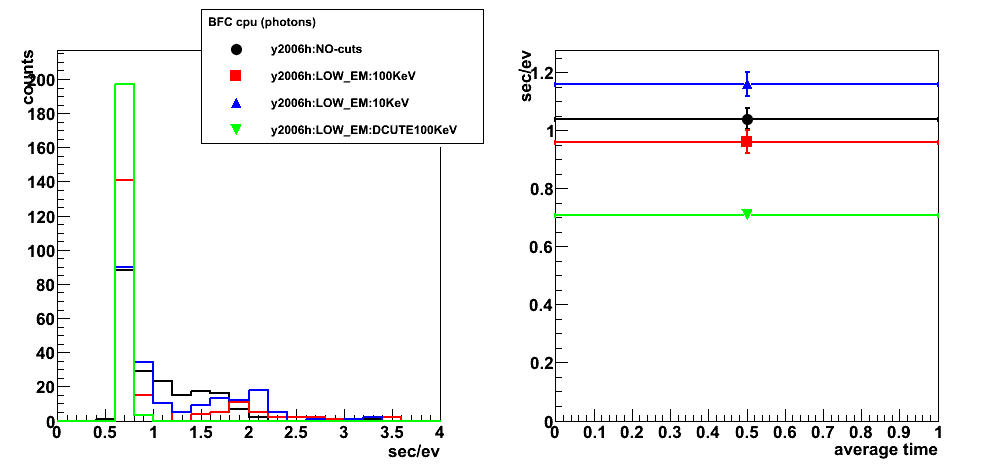

2009.07.21 EEMC tower response in Monte-Carlo

Data set and cuts:

- gamma-jet filtered Monte-Carlo

- Di-jet events from the jet finder (jets threshold: 3.5 GeV)

- parton pt bin 3-4 GeV (see pt_gamma distributions for various parton pt bins)

- Thrown photon pseudo-rapidity: eta in [1-2] range

- Requires to reconstruct photon candidate in the EEMC

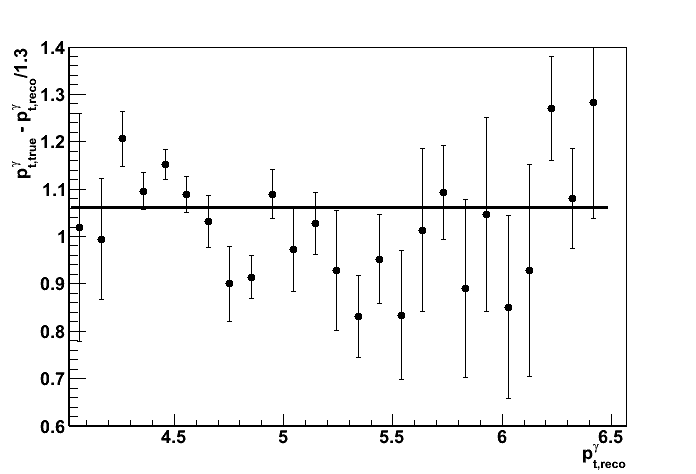

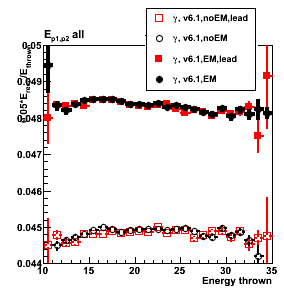

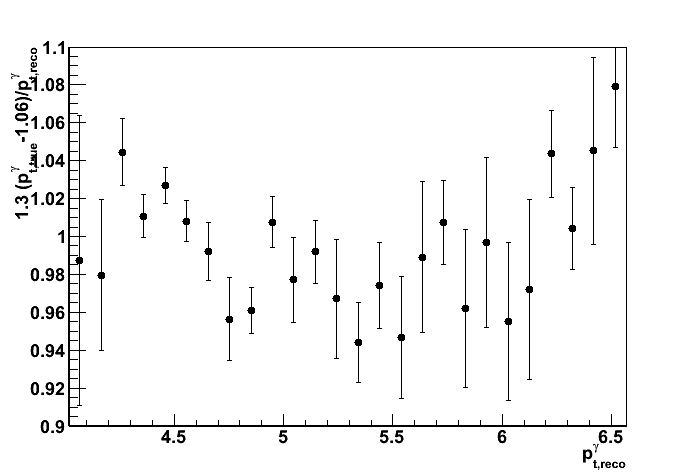

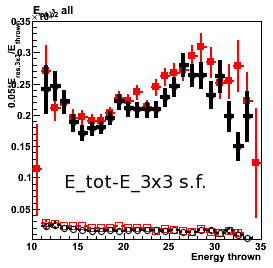

Figure 1: Average ratio: pt_true / (pt_reco/1.3) vs. pt_reco (GeV/c)

- Introduce 1.3 factor here to remove the effect of the fudge factor in slow simulator

- Since a limited partonic pt range (3-4 GeV) is used for this study,

there is an "artificial" increase of the plotted ratio in pt_gamma > 6 GeV range - Fig. 1 reflects similar features (over a limited pt range) as those found by Hal

in his single photon study (see slide 6 of SimulationStudies.ppt presentation)

Figure 2:

Average momentum difference: pt_true - (pt_reco/1.3) vs. pt_reco (GeV/c)

- Fig. 2 shows that on average in GEANT Monte-Carlo we miss ~1GeV independent on the photon pt.

EEMC detector response can be still linear even if the ratio in Fig. 1 is not flat. - Usage of fixed 1.3 (or others, like 1.25) fudge factors are not justified.

- It seems that using pt-dependent fudge factor (like it is done in this Jason's study)

is also unjustified, since the same effects (flat ratio of pt_reco/pt_true ~ 1)

can be reached by subtracting 1 GeV from the cluster energy (See Fig. 3).

Figure 3: Average ratio: (pt_true -1.06) (pt_reco/1.3) vs. pt_reco (GeV/c)

Similar to Fig. 1, but with the true photon pt reduced by 1.06 GeV

Resulting true/reco pt ratio is flat in 4-6 GeV range.

Before further pursuing our efforts in tuning the tower energy response in the Monte-Carlo,

needs to address the observed energy loss difference in the fisrt layer of the BEMC/EEMC detector.

See Jason's blog post from 2009.07.16 for more details:

Comparison muon energy deposit in the 1st BEMC/EEMC layers

08 Aug

August 2009 posts

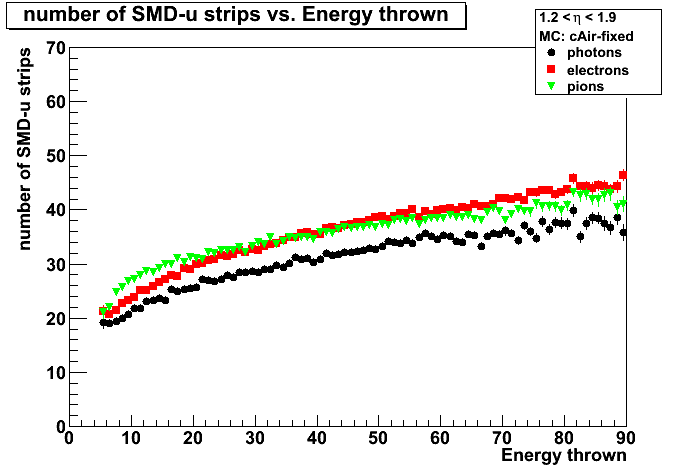

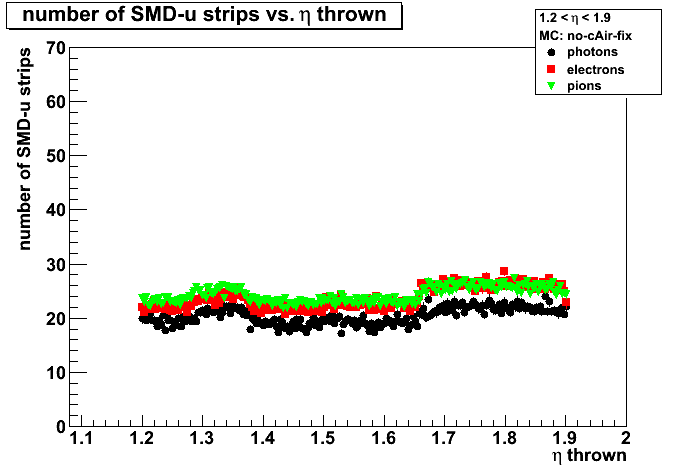

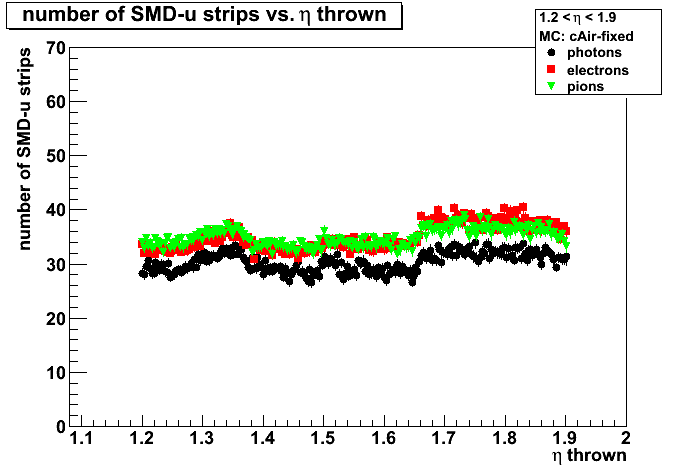

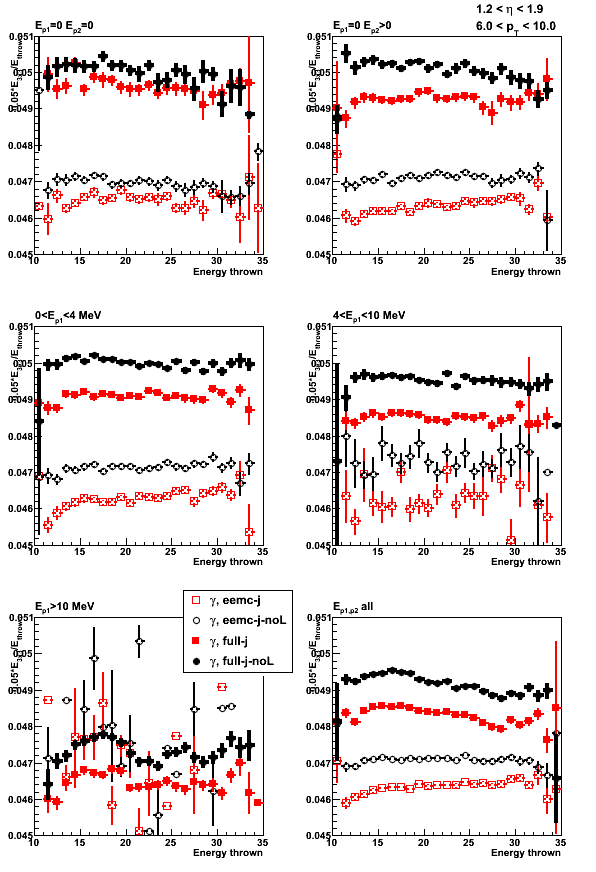

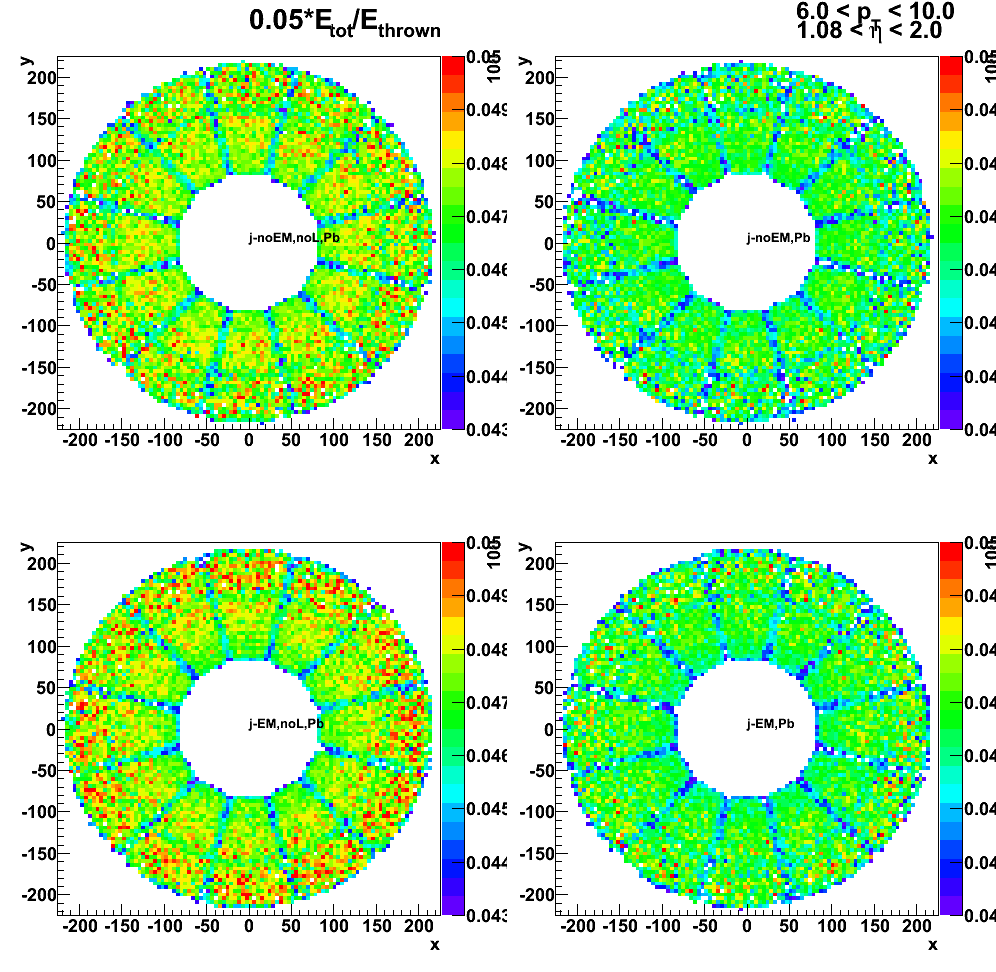

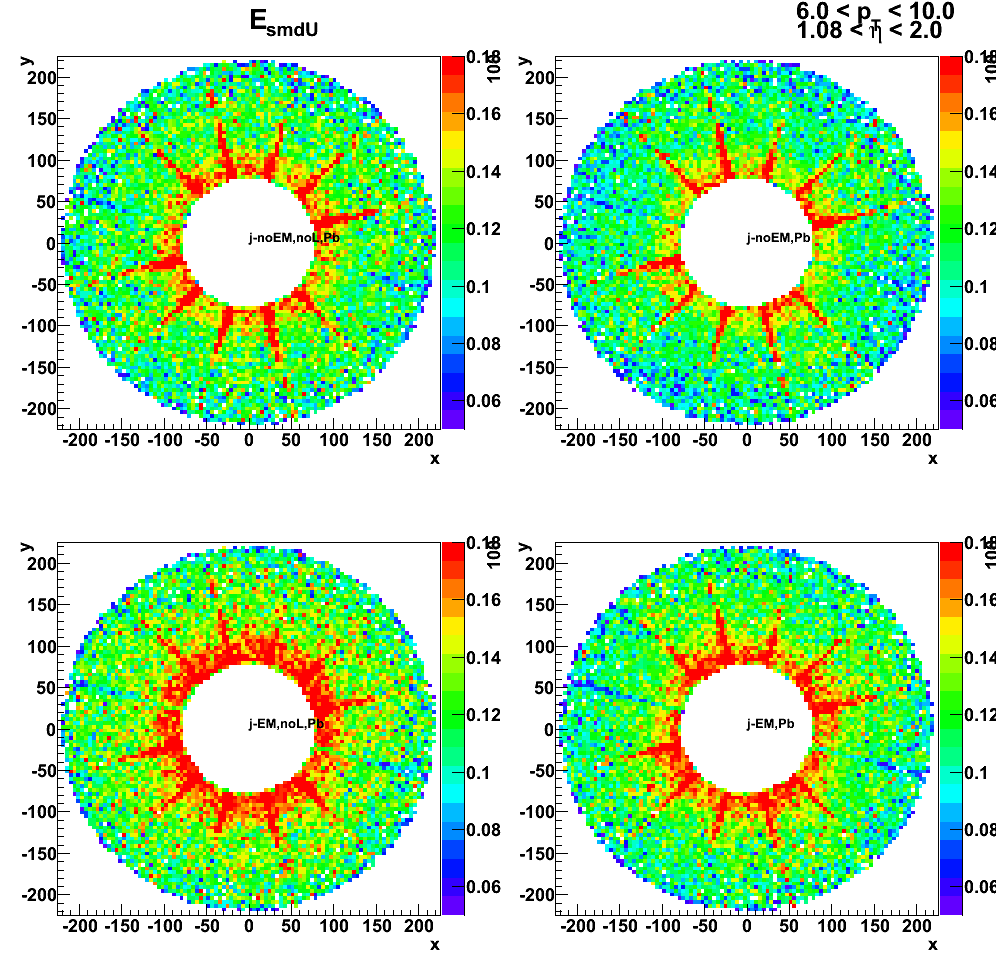

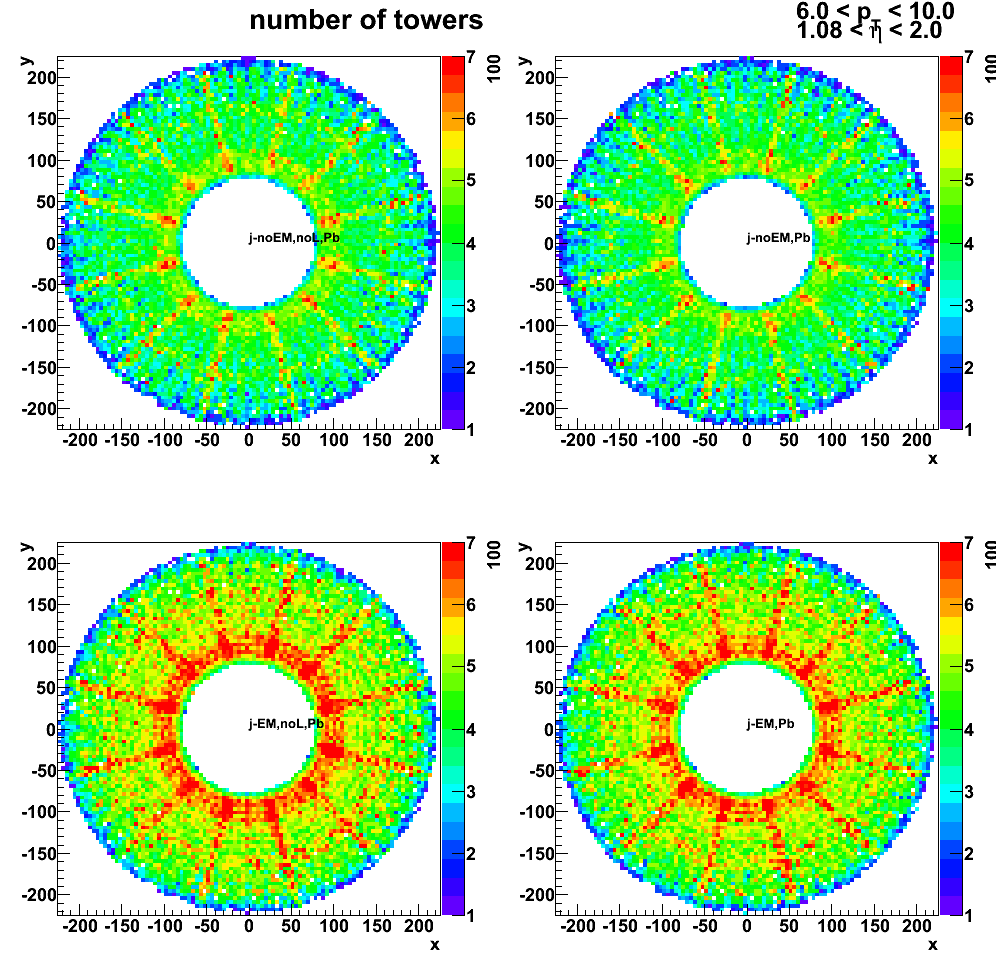

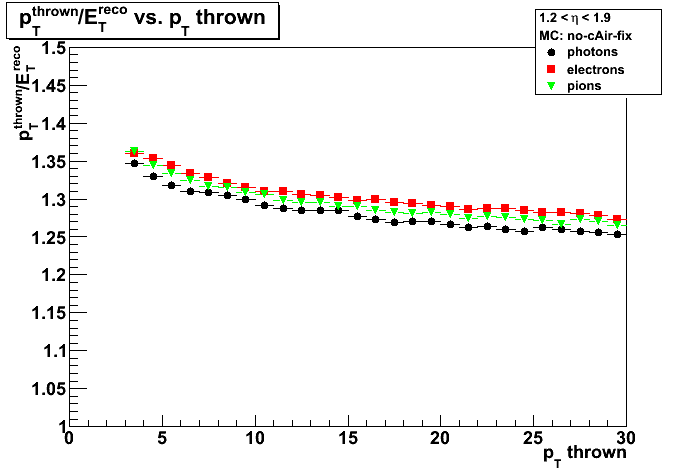

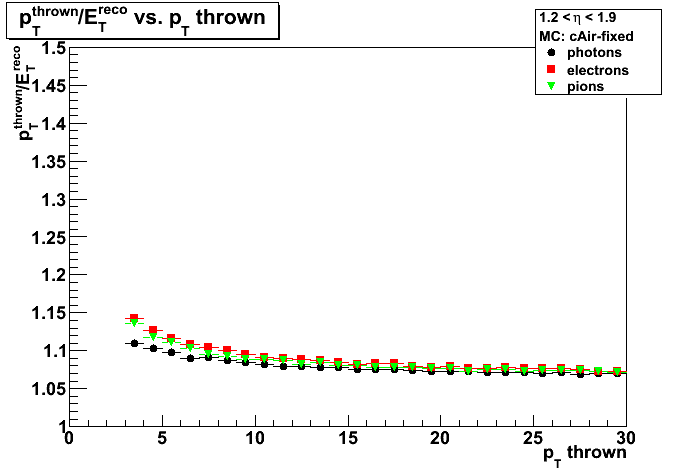

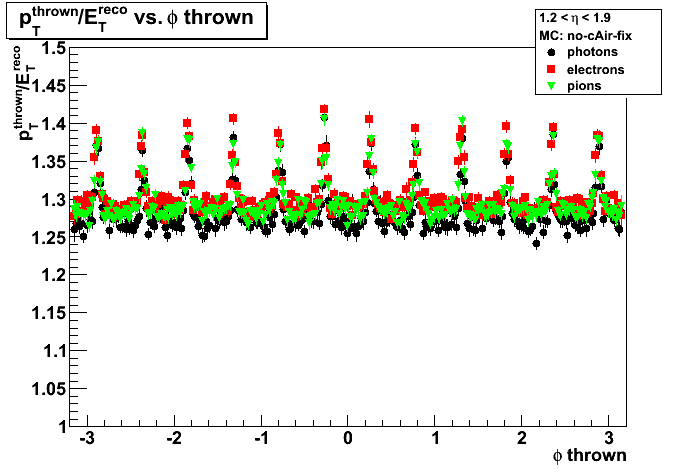

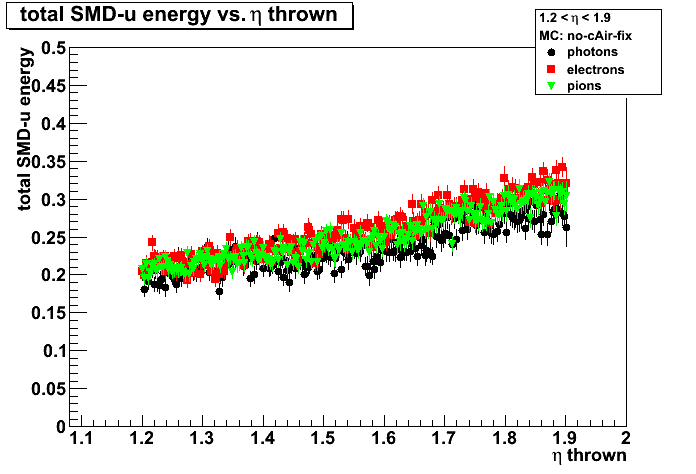

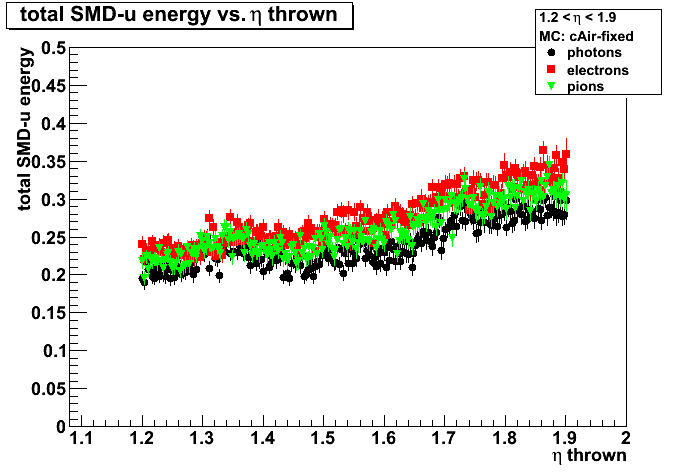

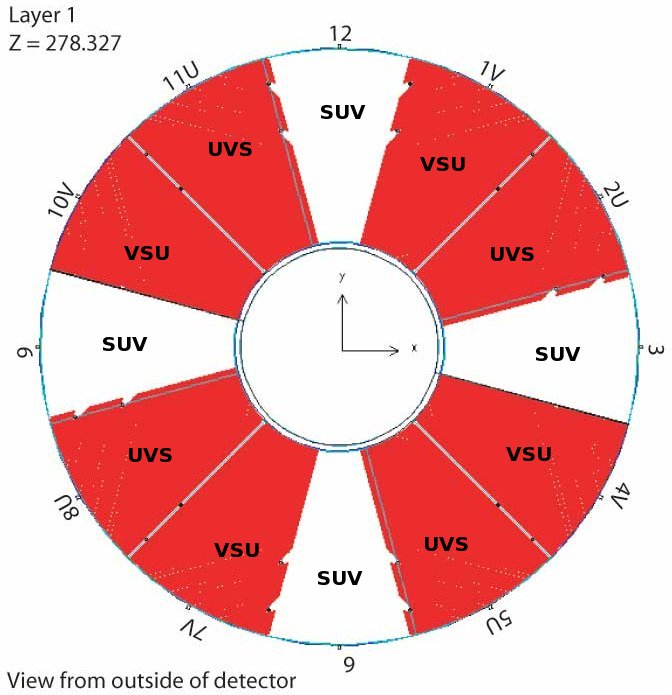

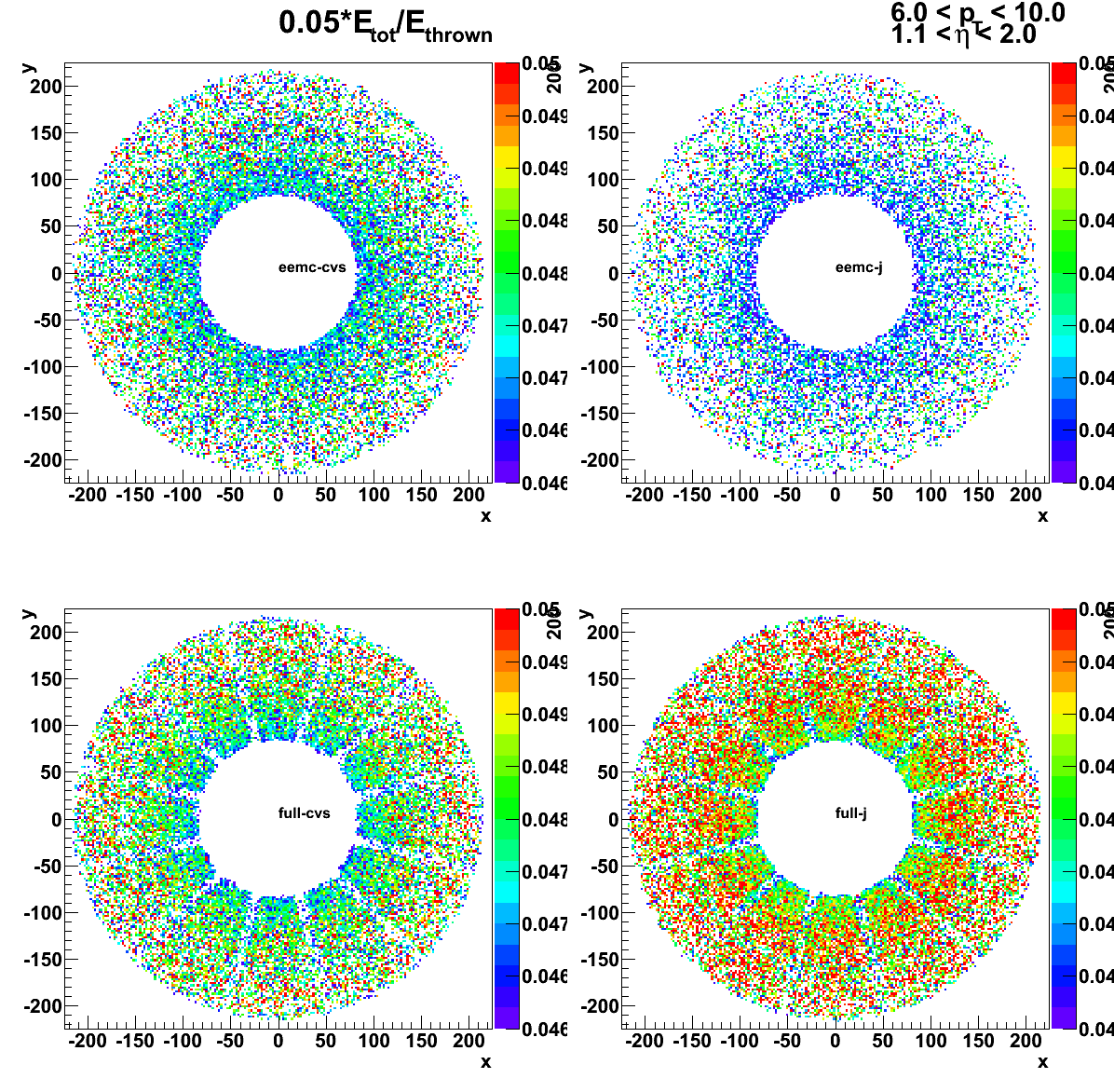

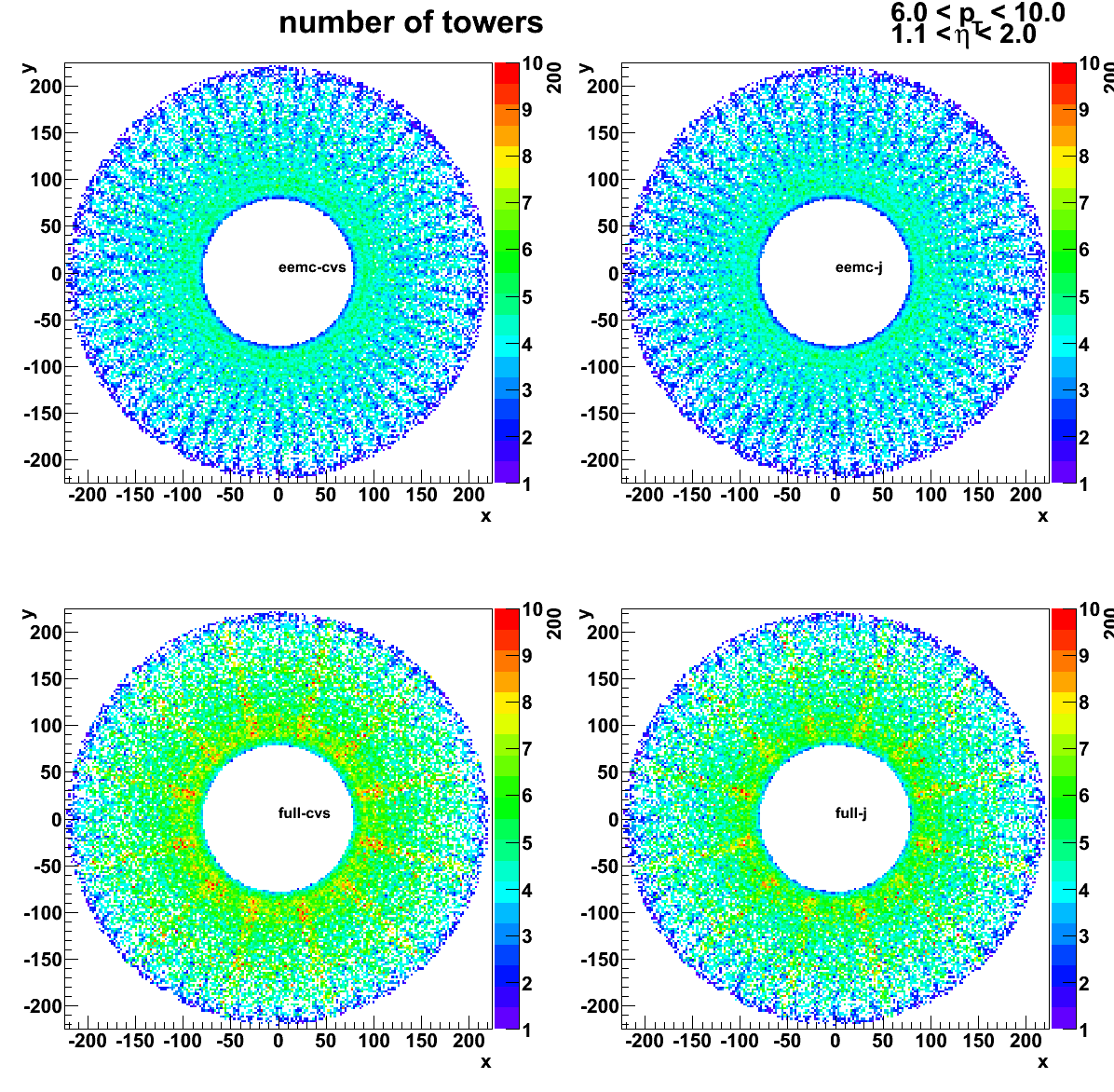

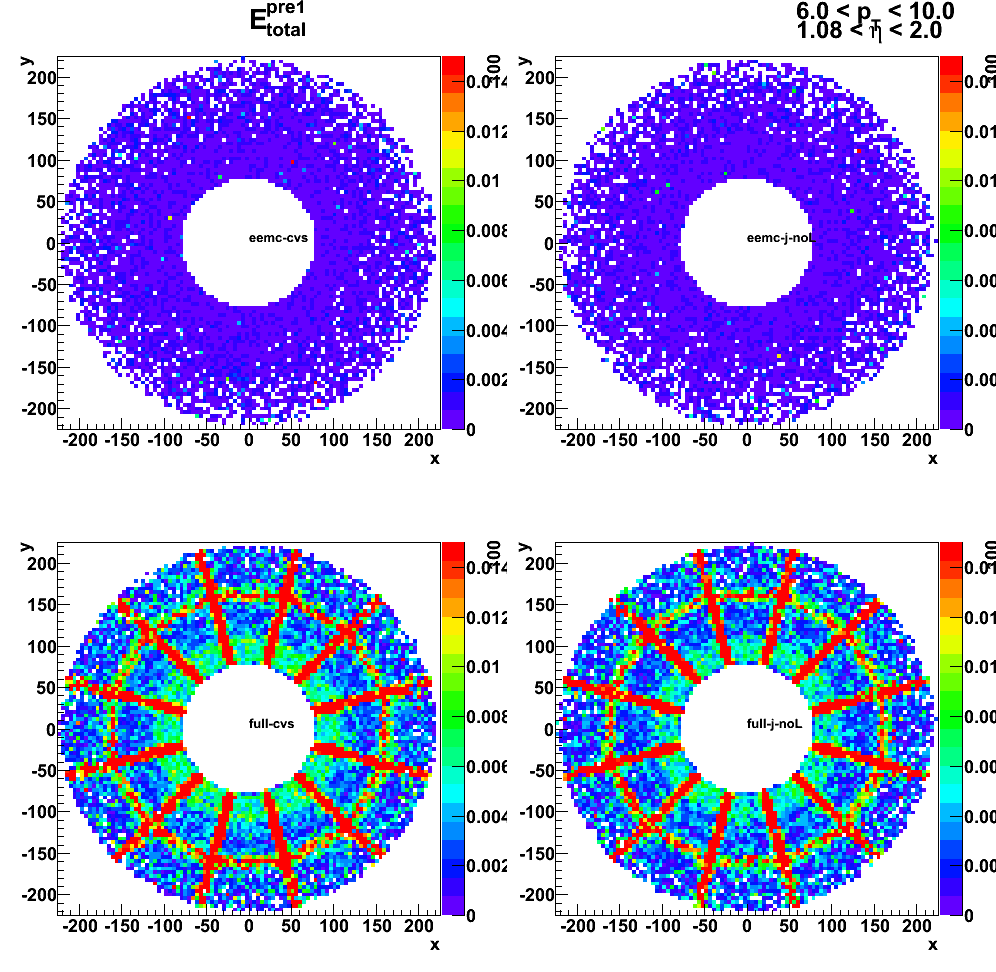

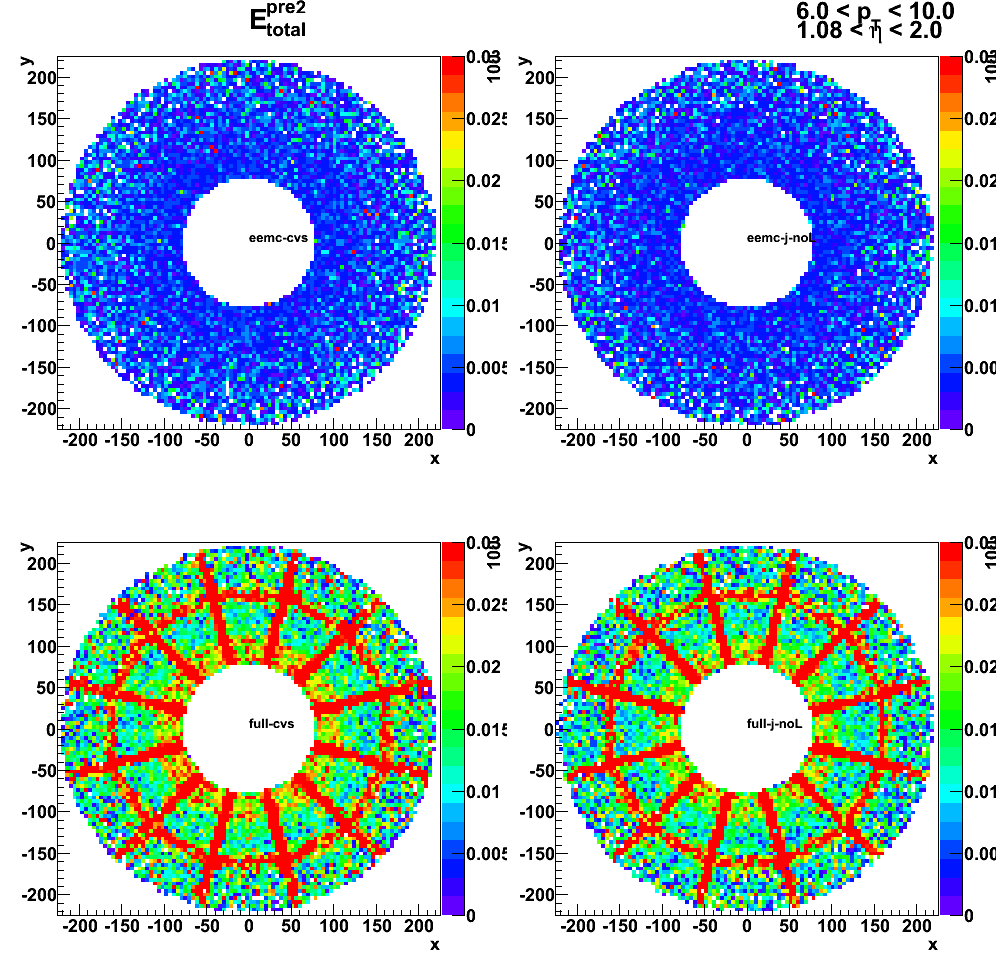

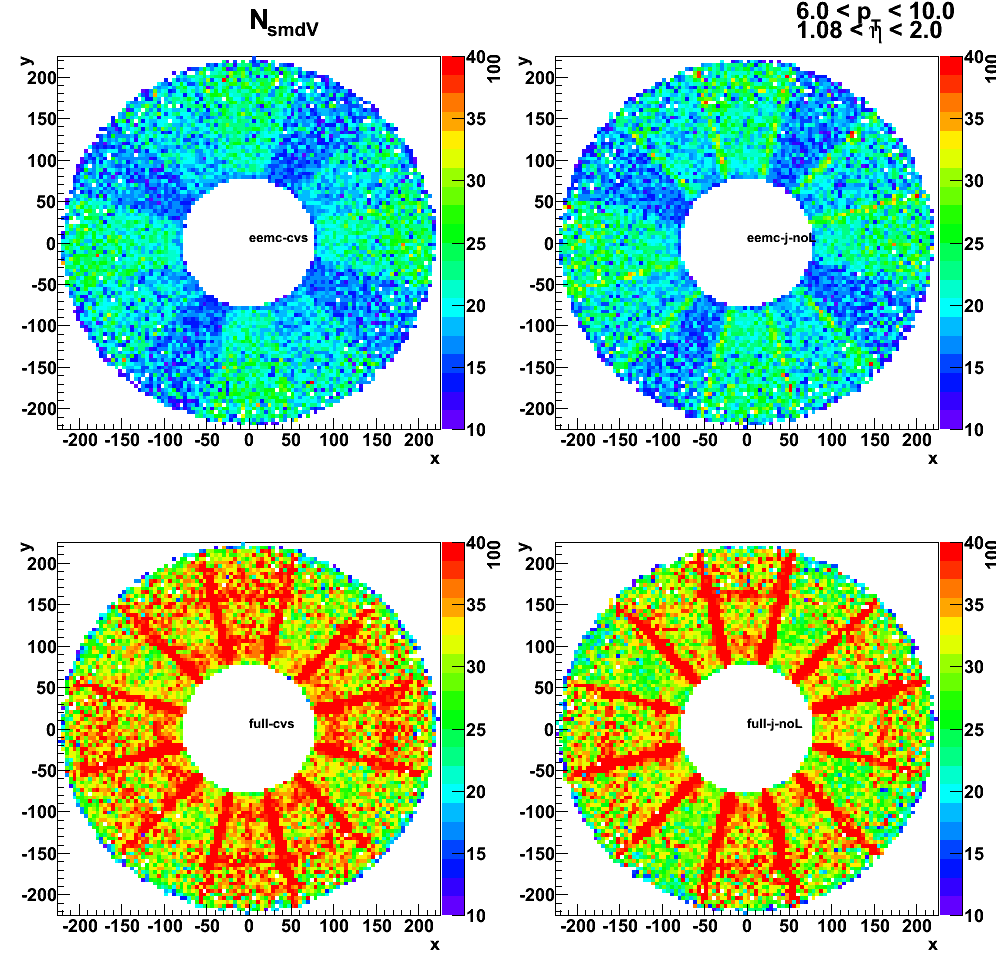

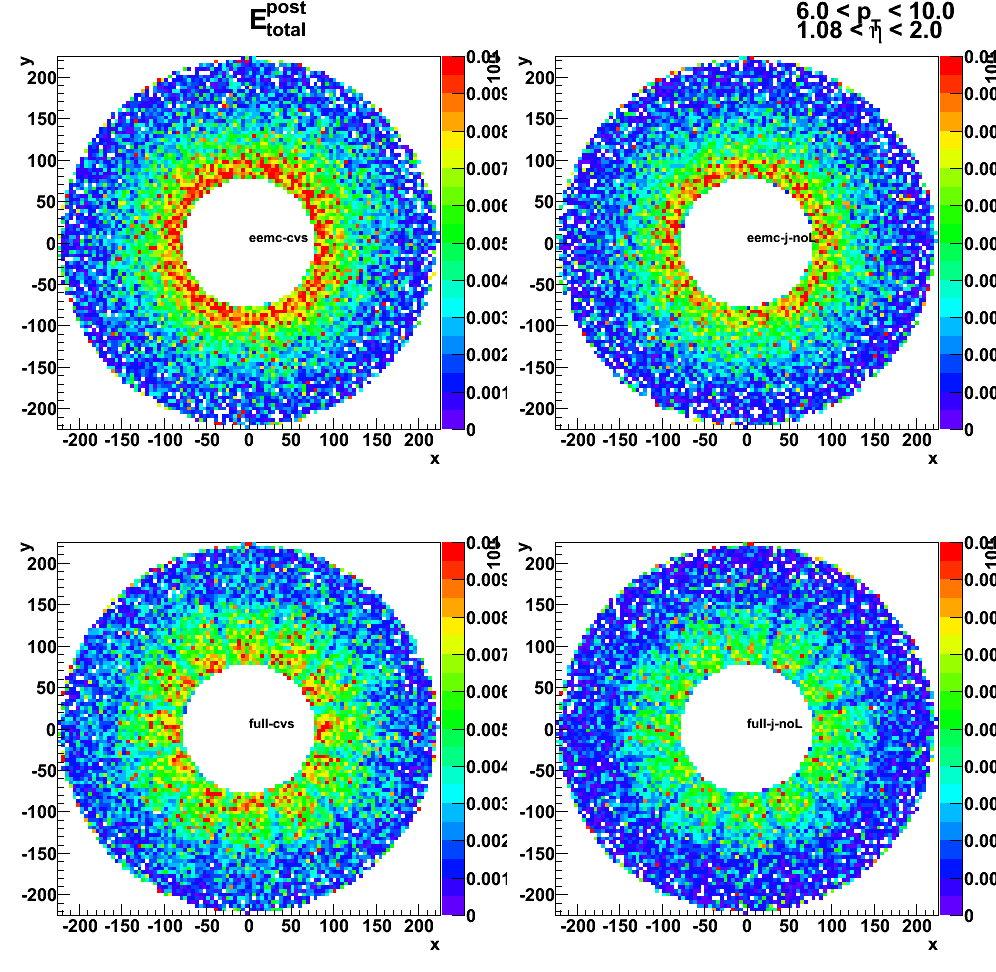

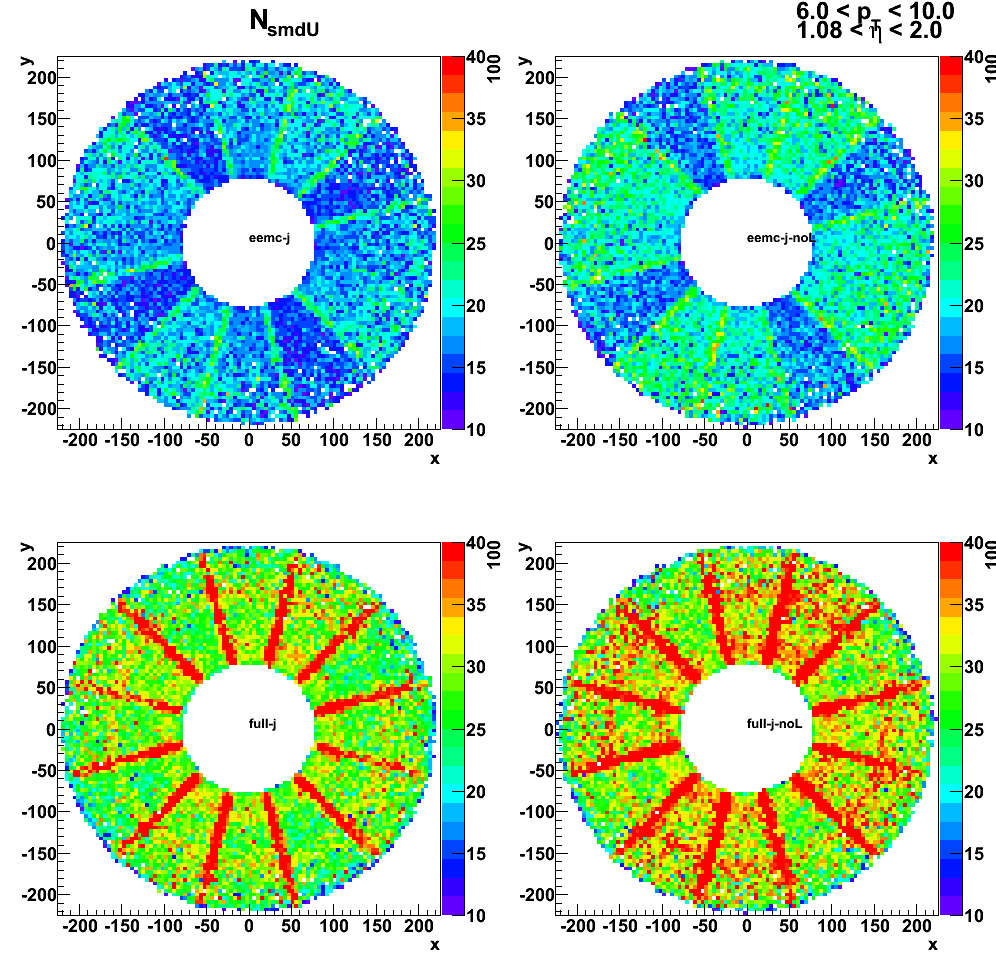

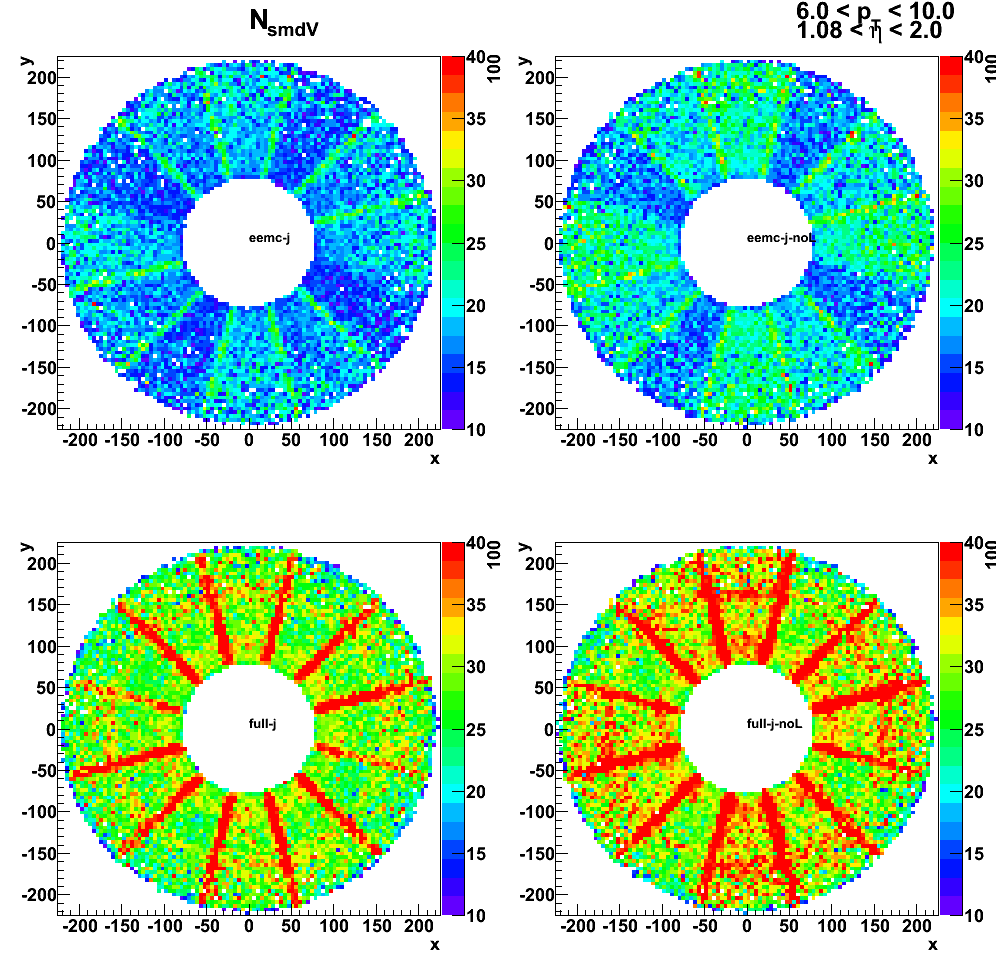

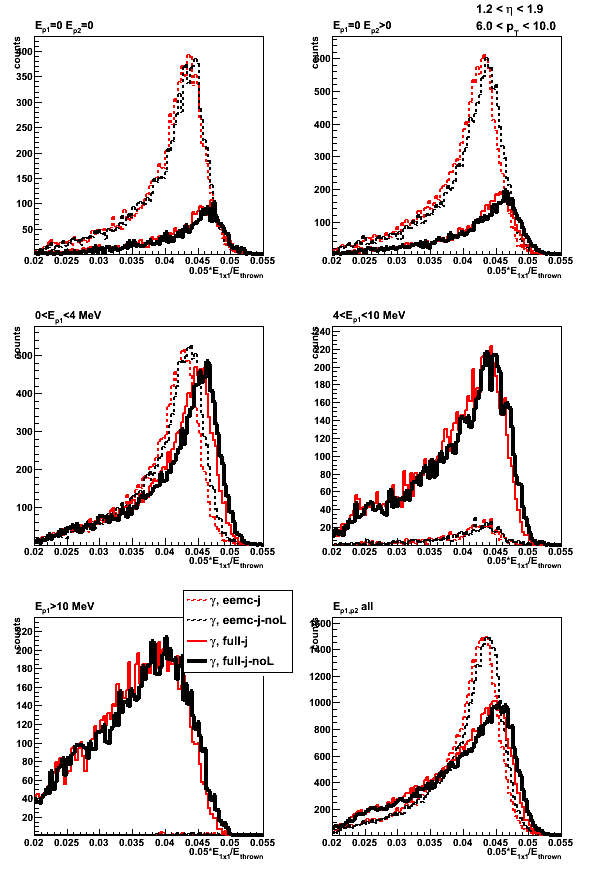

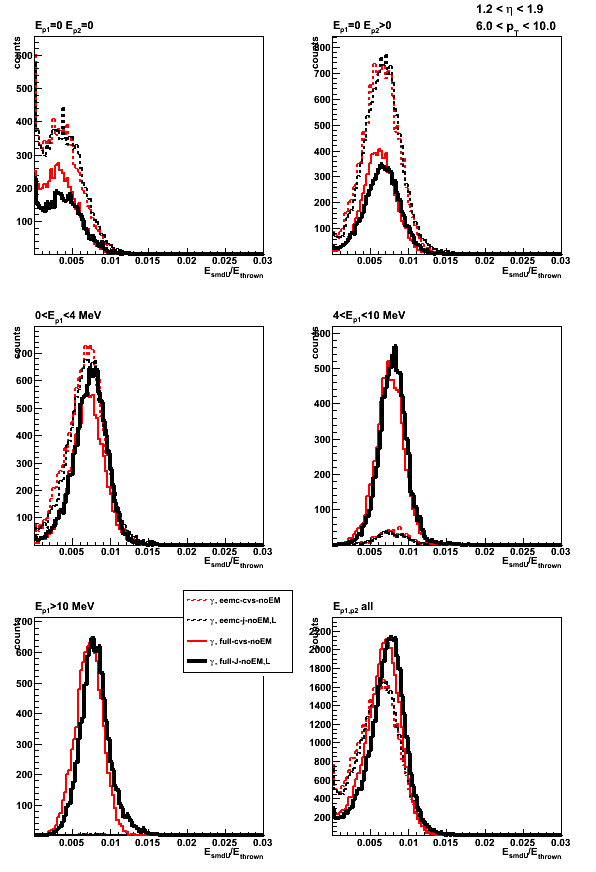

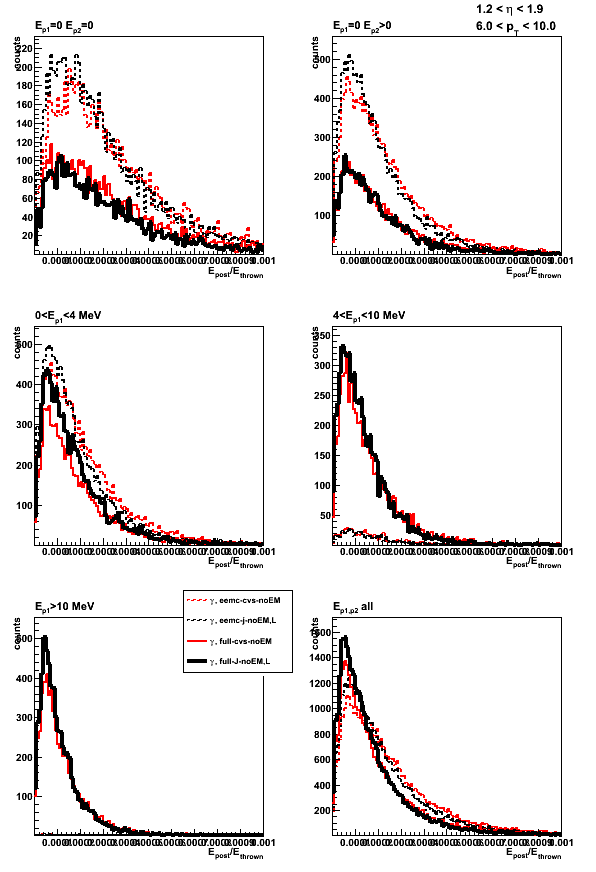

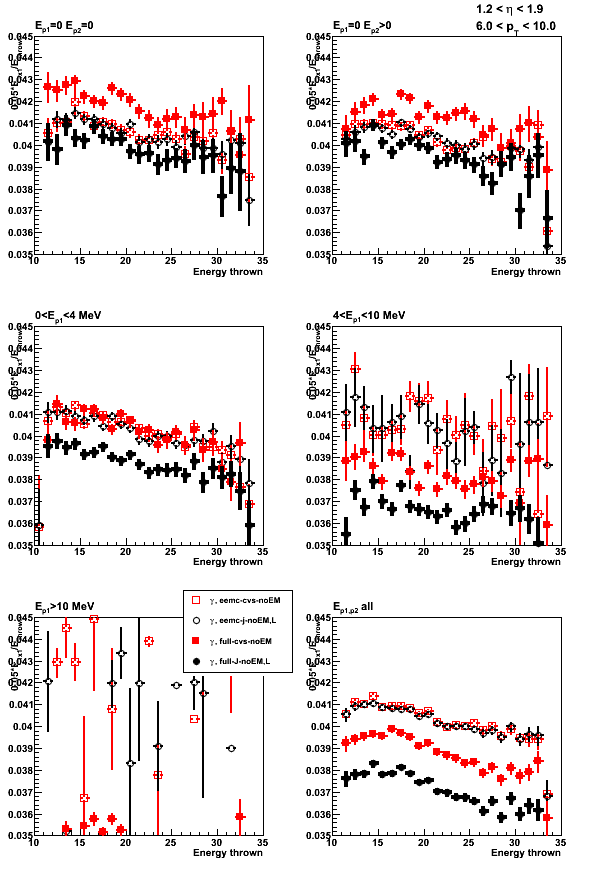

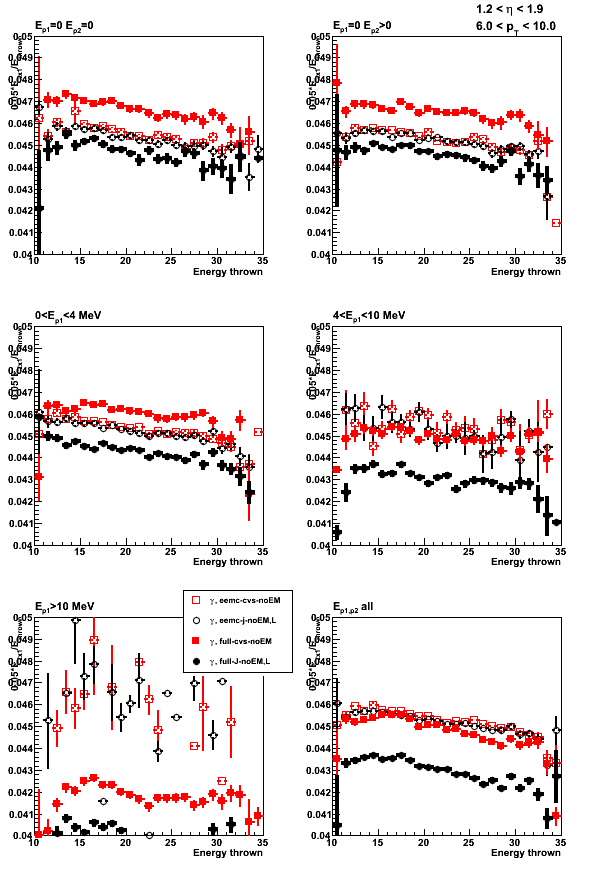

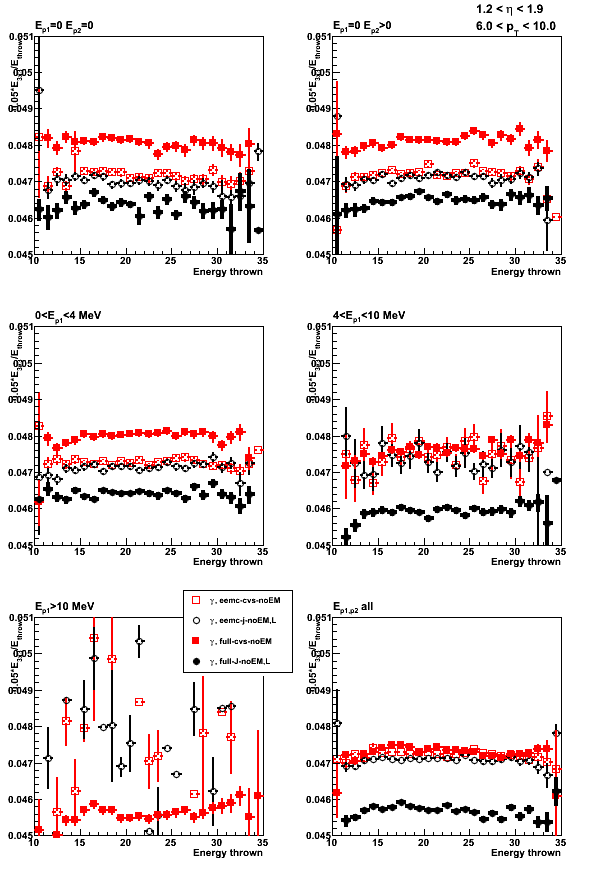

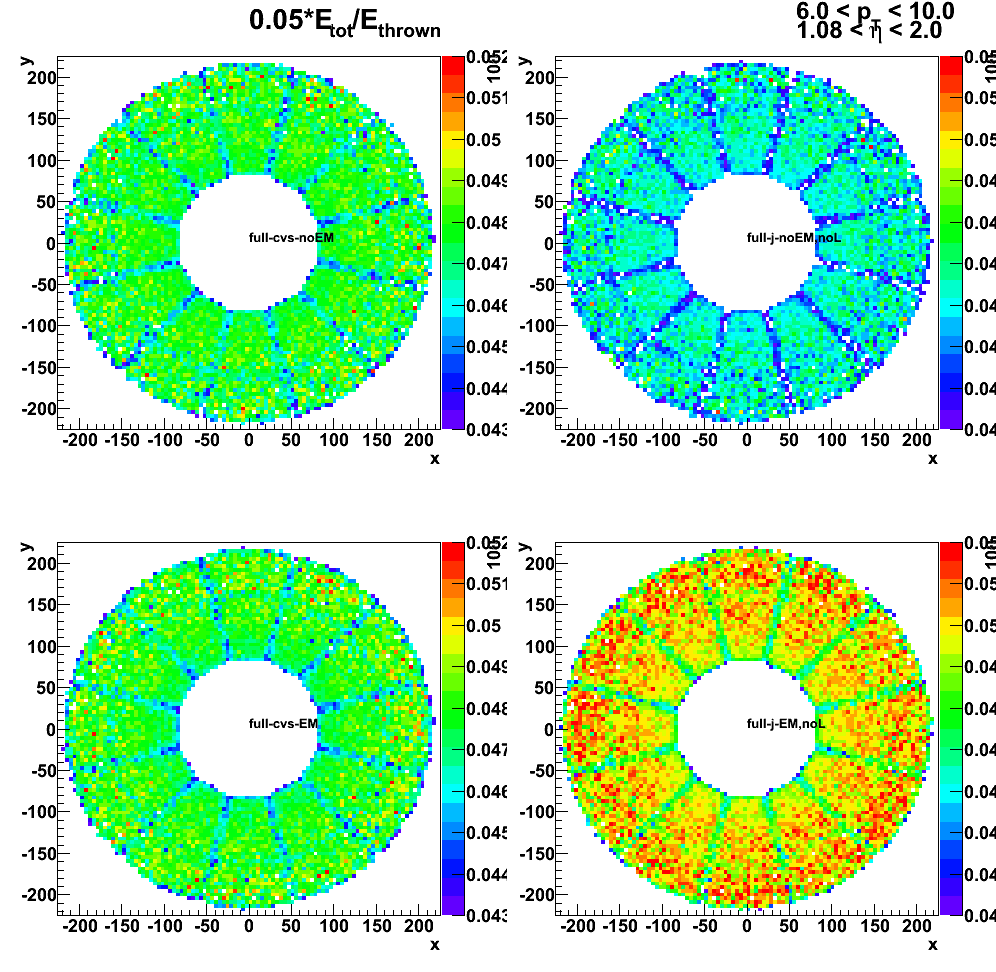

2009.08.24 Test of corrected EEMC geometry

Test of corrected EEMC geometry (bug 1618)

Monte-Carlo setup:

- One particle per event (photons, electrons, and pions)

- Full STAR 2006 geometry.

In Kumac file: detp geom y2006g; gexec $STAR_LIB/geometry.so - Flat in eta (1.08-2.0), phi (0,2pi), and pt (3-30 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy (no EEMC SlowSimulator in chain)

what assumes fixed sampling fraction of 0.05 (5%)

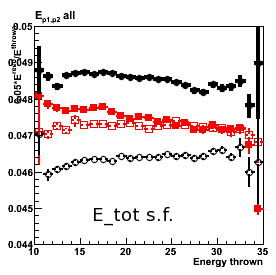

Some definitions:

- Et correction factor : average p_T^thrown / E_T^{reco}.

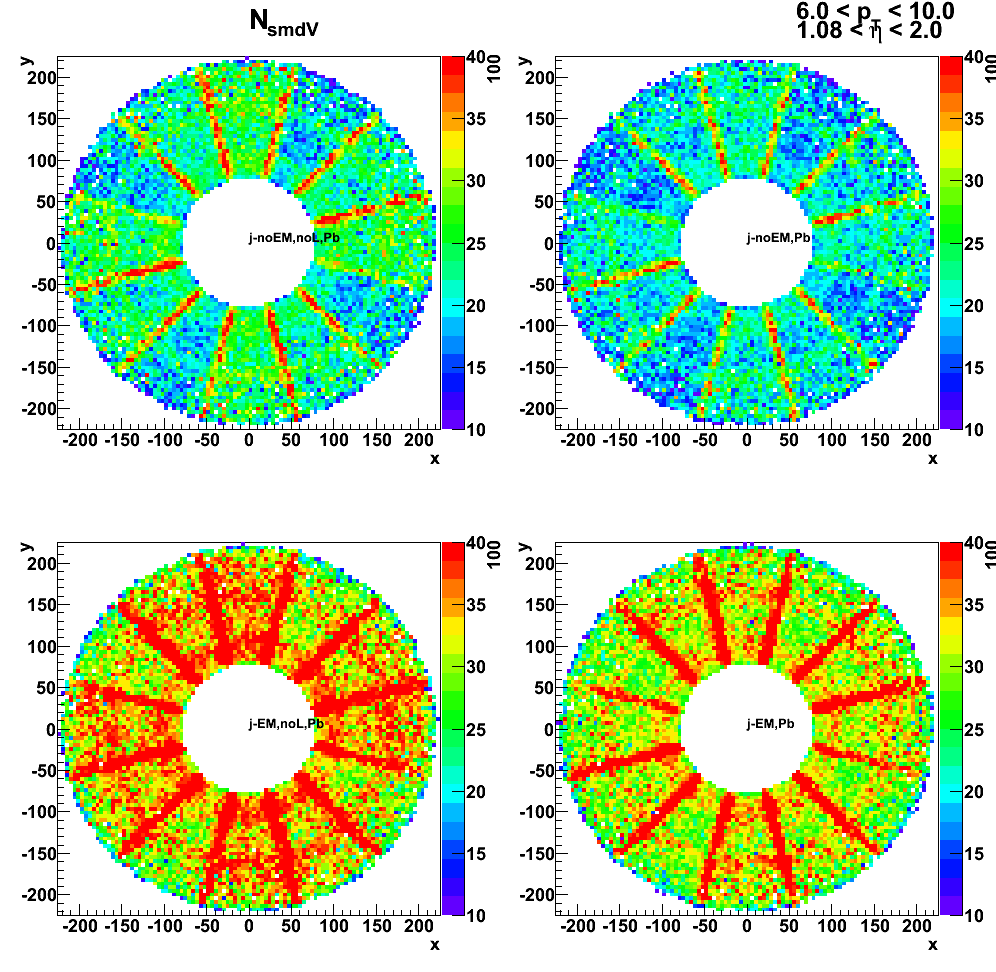

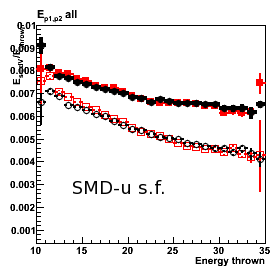

E_T^{reco} is the total energy in the Endcap Calorimeter (from A2Emaker) - Sampling fraction: average 0.05 * Energy^{reco} / Energy^thrown.

- SMD energy: average energy in all strips fired (u-plane used for this post)

- Number of SMD strips fired: average total number of strips fired (u-plane used for this post)

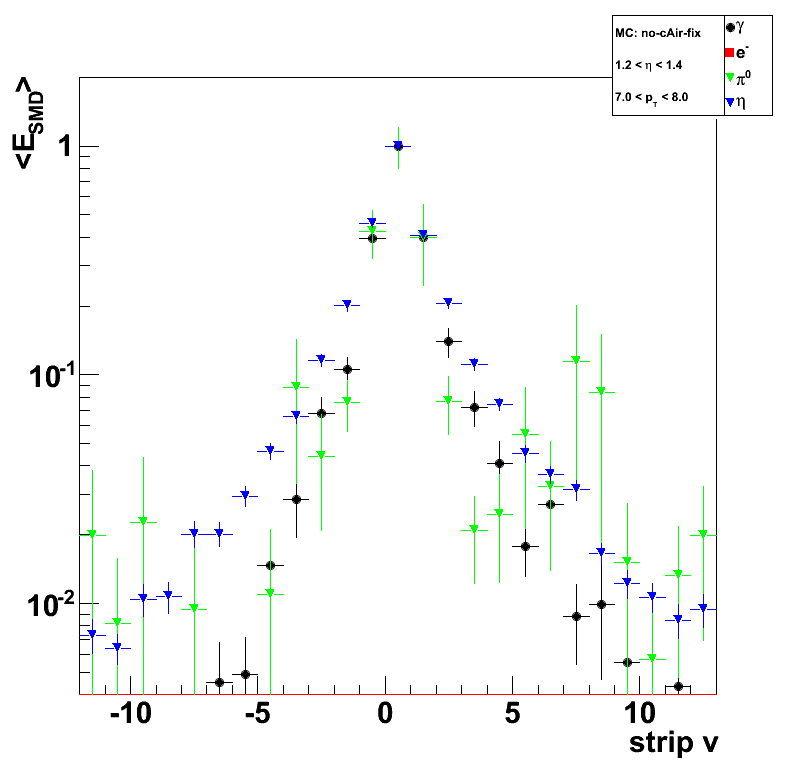

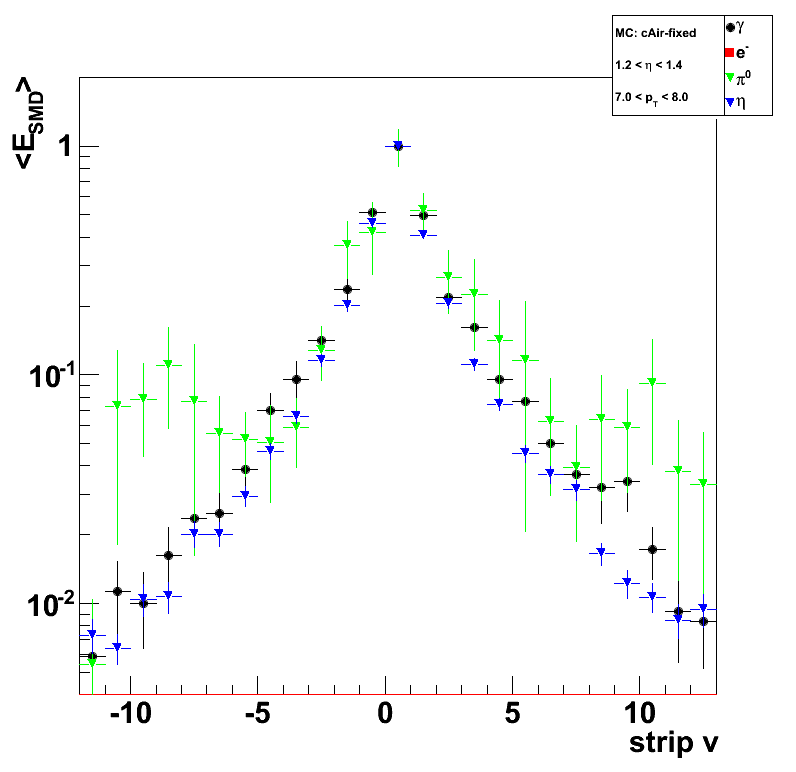

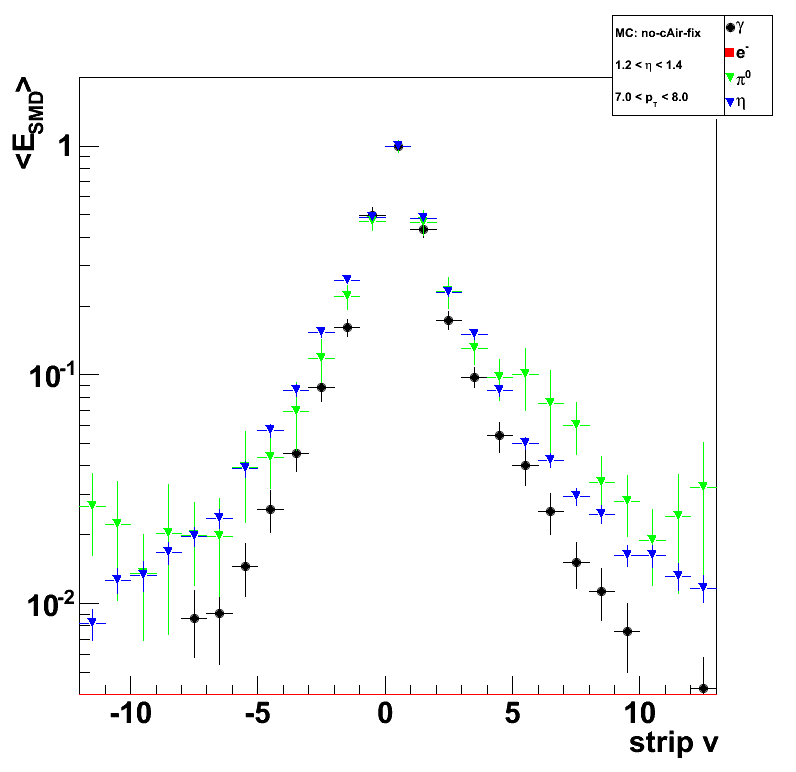

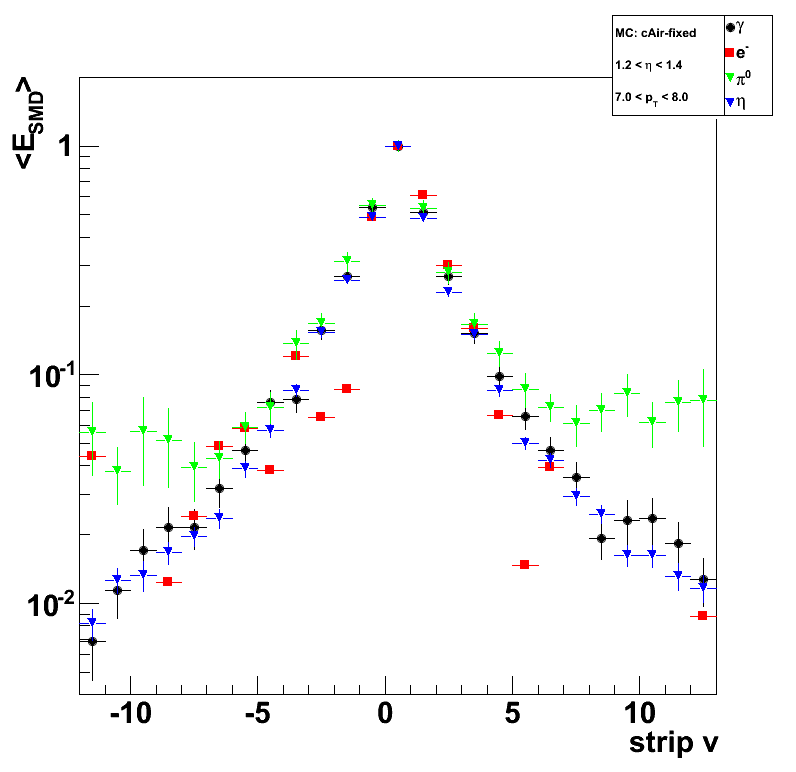

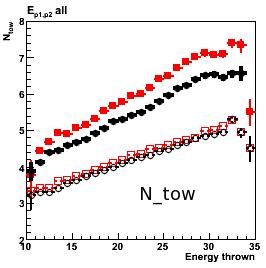

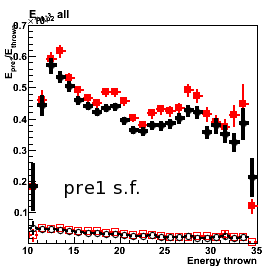

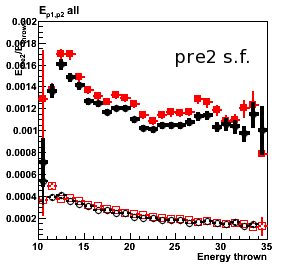

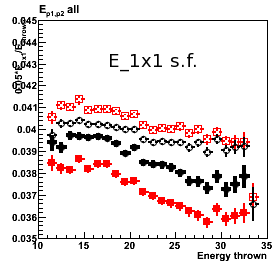

Notations used in the plots:

- Left plots: no cAir fix

- Right plots: cAir-fixed

- Photons: black

- Electrons: red

- Pions: green

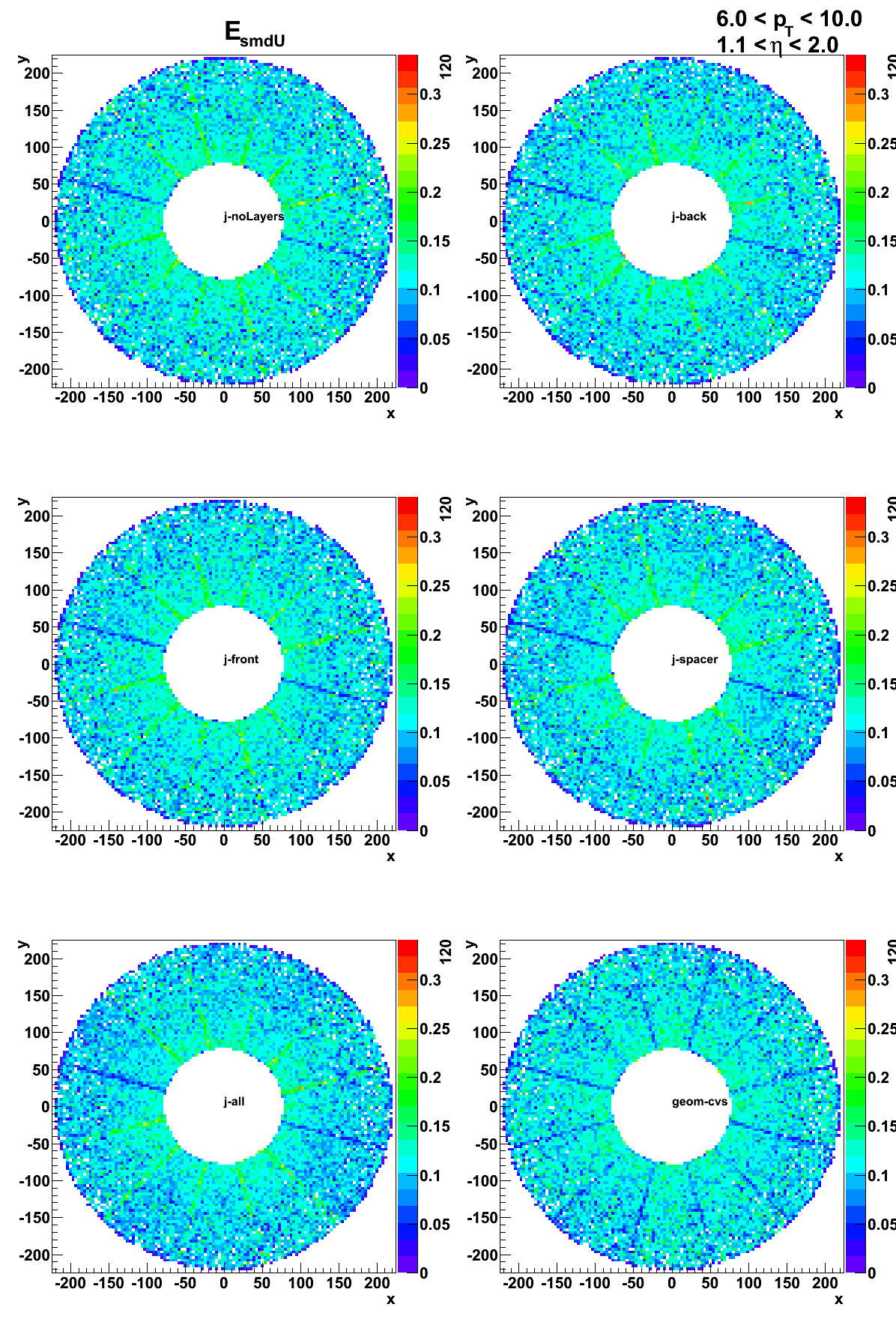

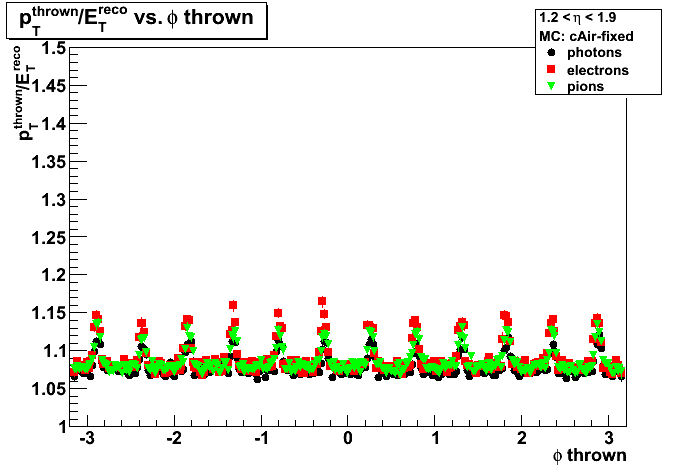

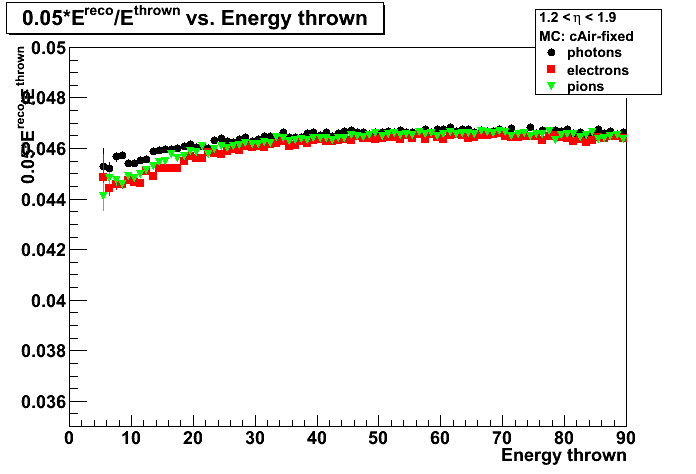

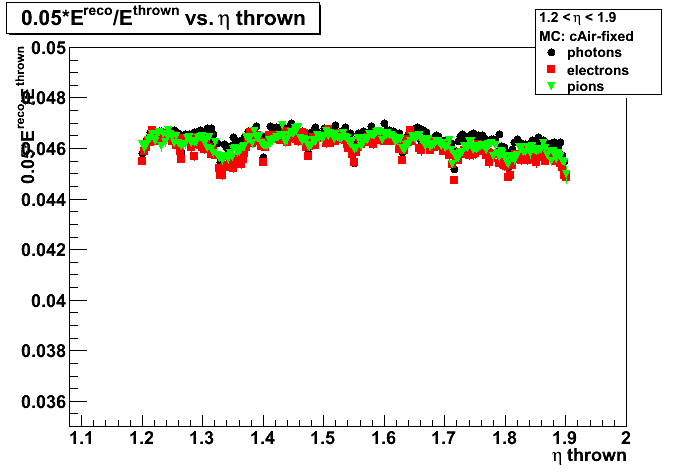

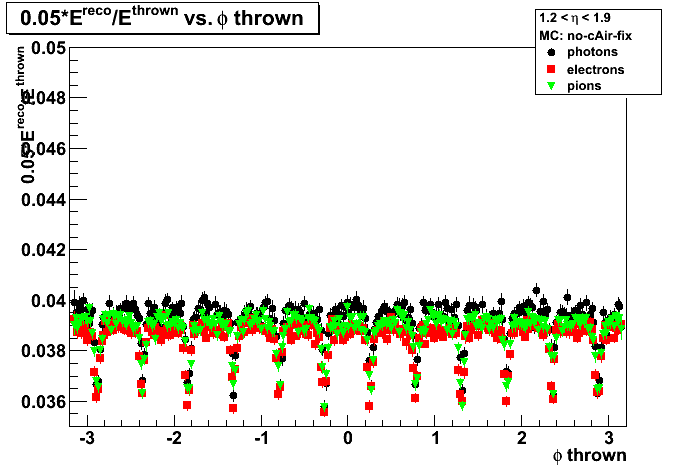

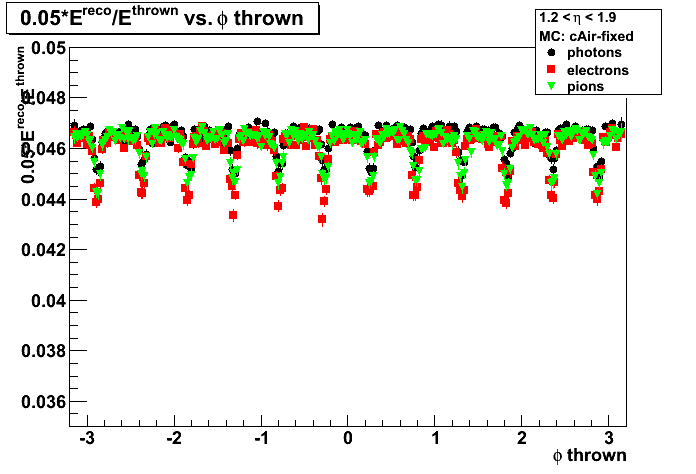

Et correction

Note: compare "Left" plots with Brians old results

Figure 1a: Et correction factor vs. pt thrown

Figure 1b: Et correction factor vs. eta thrown

Figure 1c: Et correction factor vs. phi thrown

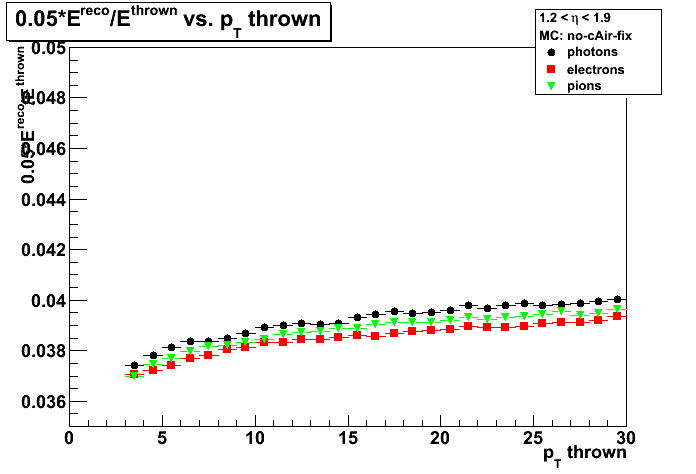

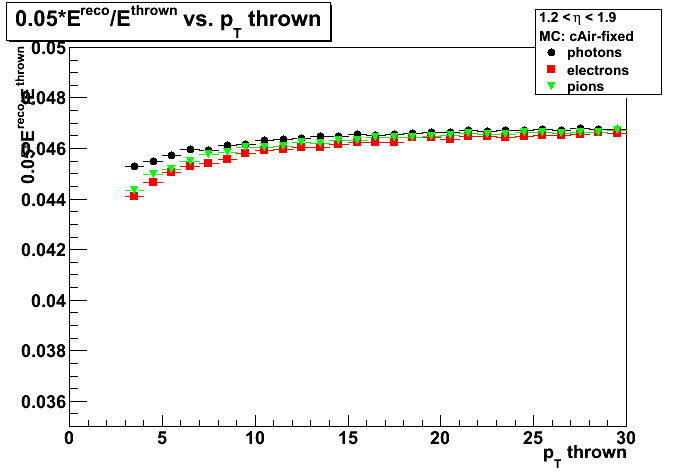

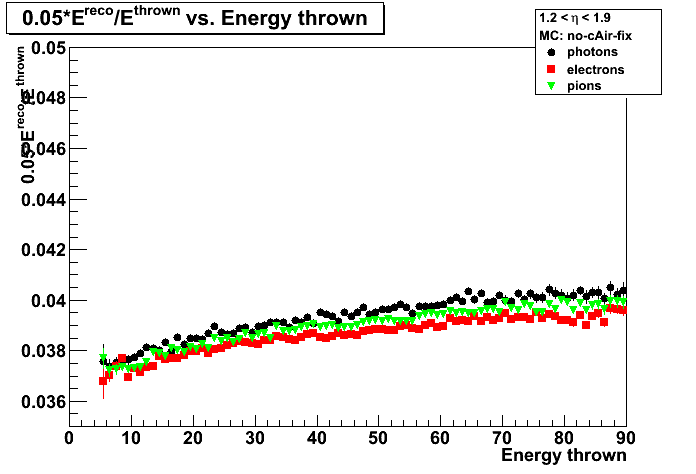

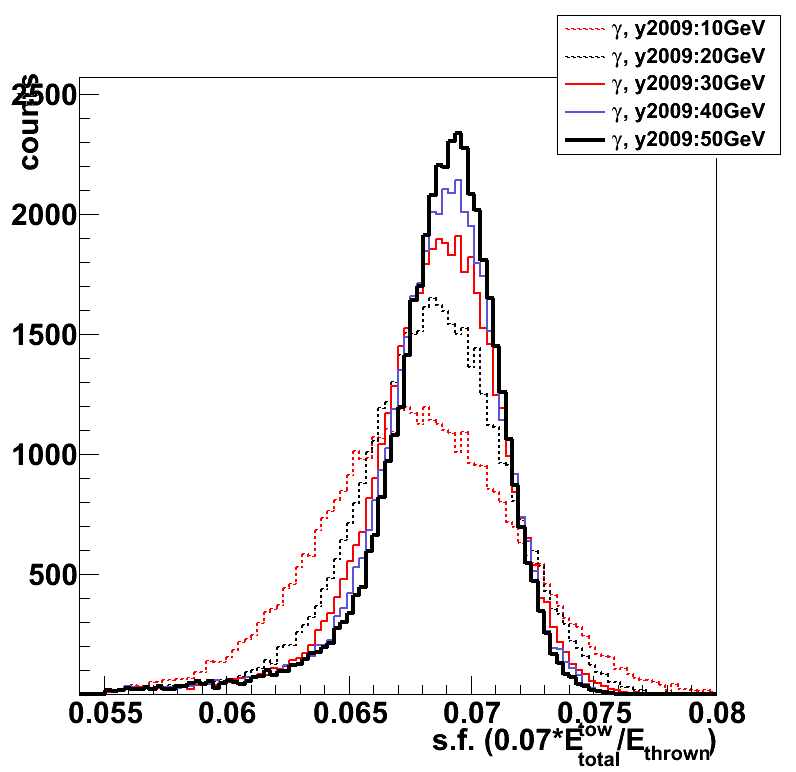

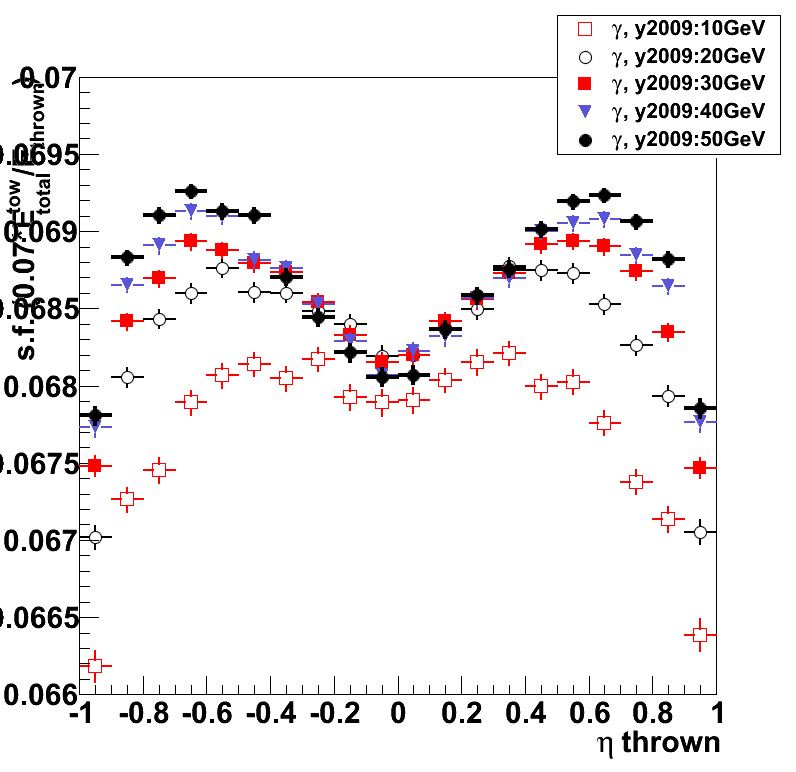

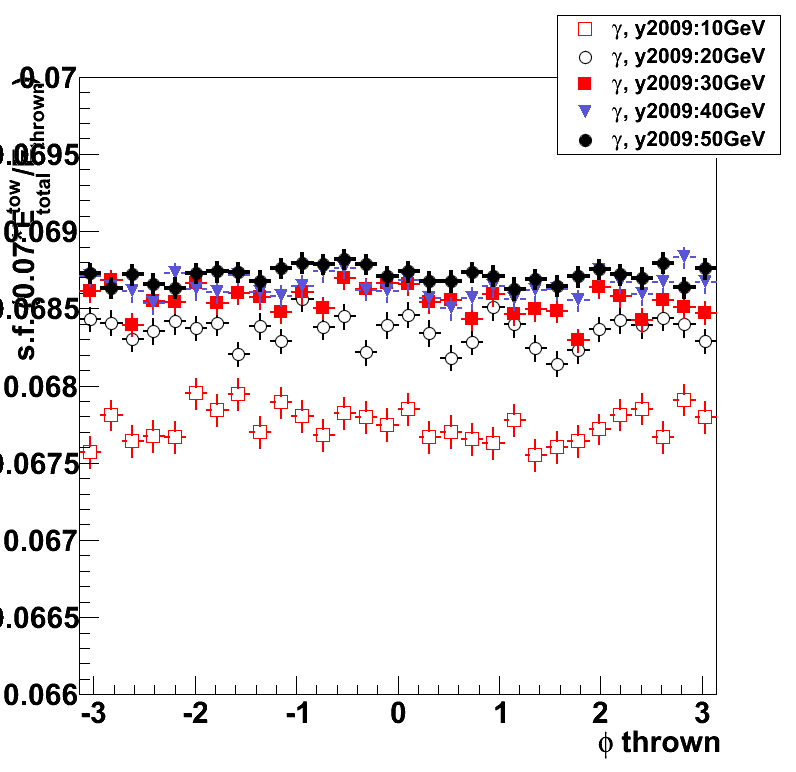

Sampling fraction

Note: compare "Right" plots with Jason results with EEMC only geometry

Figure 2a: Sampling fraction vs. pt thrown

Figure 2b: Sampling fraction vs. energy thrown

Figure 2c: Sampling fraction vs. eta thrown

Figure 2d: Sampling fraction vs. phi thrown

SMD energy

Figure 3a: SMD energy vs. energy thrown

Figure 3b: SMD energy vs. eta thrown

Number of SMD strips fired

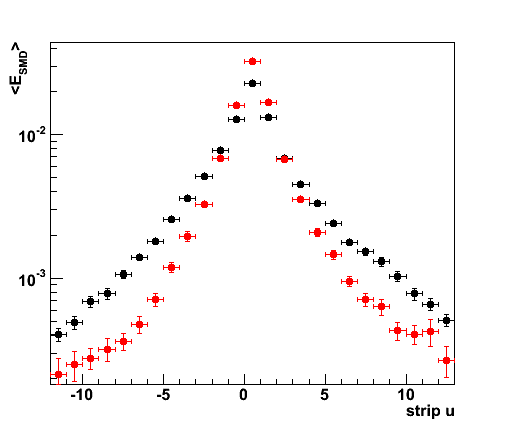

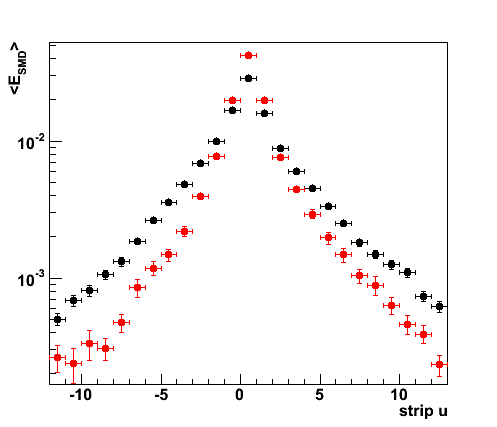

2009.08.25 Test of corrected EEMC geometry: shower shapes

Test of corrected EEMC geometry (bug 1618)

Monte-Carlo setup is desribed here

- One particle per event (photons, electrons, and pions)

- Full STAR 2006 geometry.

In Kumac file: detp geom y2006g; gexec $STAR_LIB/geometry.so - Flat in eta (1.08-2.0), phi (0,2pi), and pt (3-30 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy (no EEMC SlowSimulator in chain)

what assumes fixed sampling fraction of 0.05 (5%) - Vertex z=0

- ~50K/per particle type

- Non-zero energy: 3 sigma above pedestal

Figure 1:Single photon shower shape before (red) and after (black) EEMC cAir bug fixed

pt=7-8GeV, eta=1.2-1.4 (left), eta=1.6-1.8 (right)

Figure 2: Single photon shower shape vs. data

Monte-Carlo: pt=7-10GeV, eta=1.6-1.8

data: no pre-shower1,2; pt_photon>7, pt_jet>5. no eta cuts.

(see Fig. 1 from here for other pre-shower conditions)

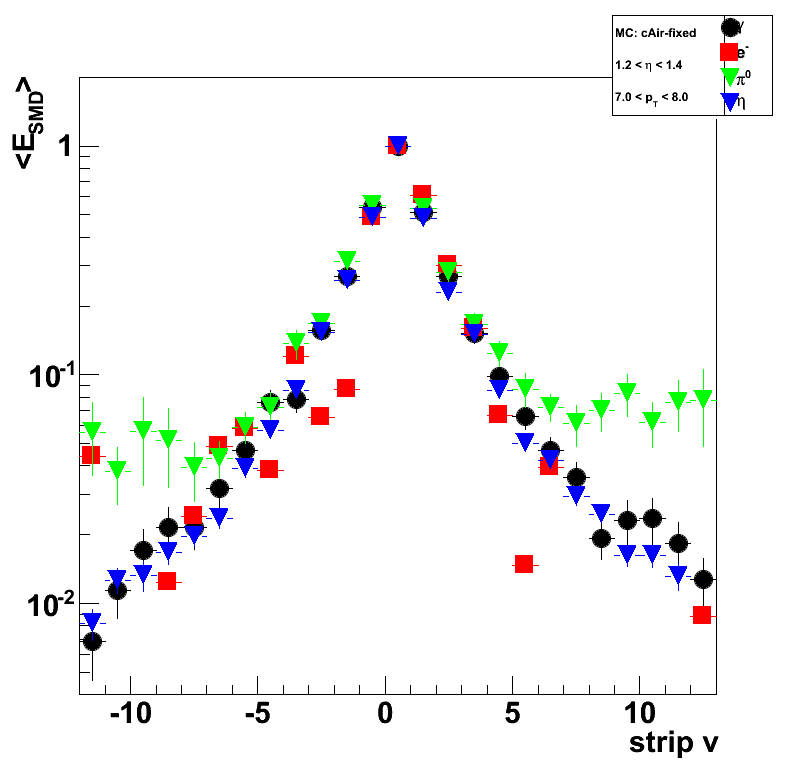

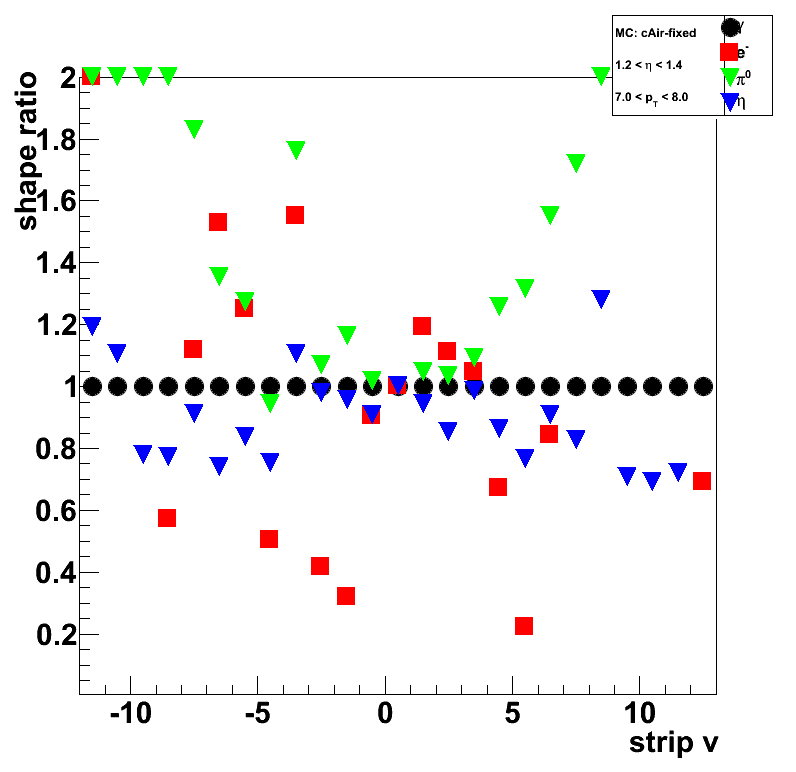

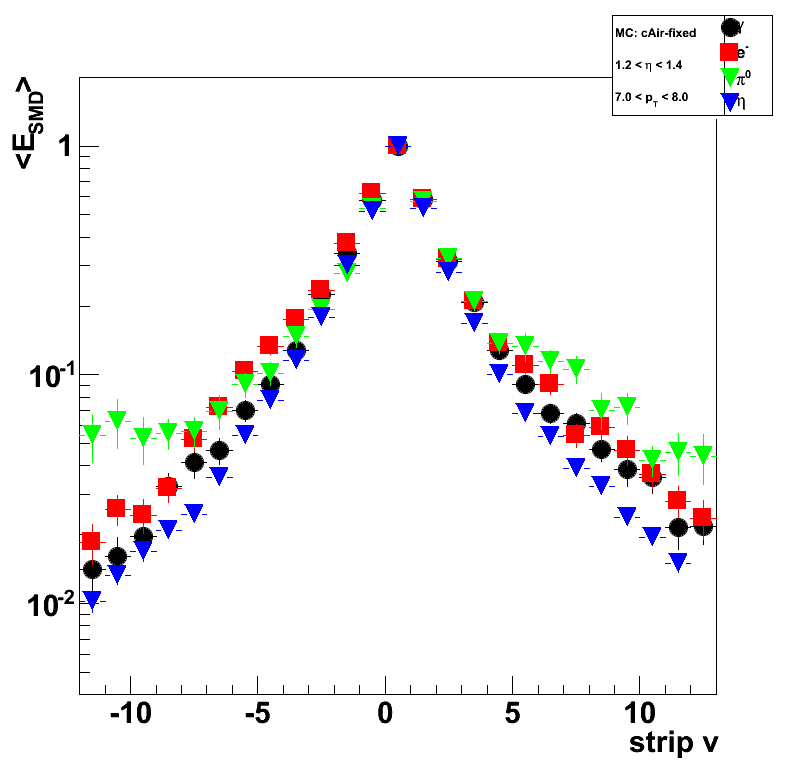

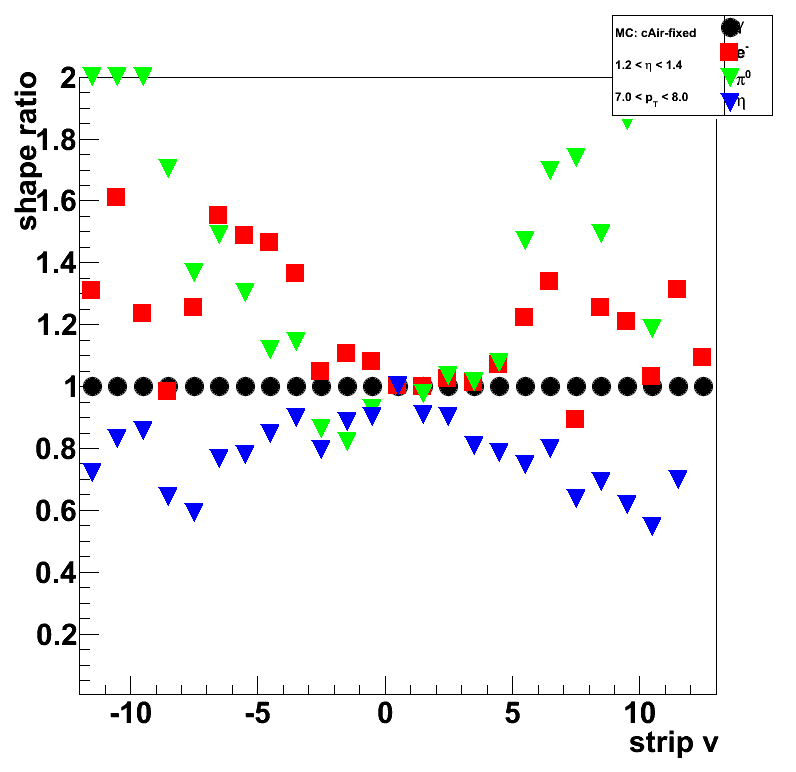

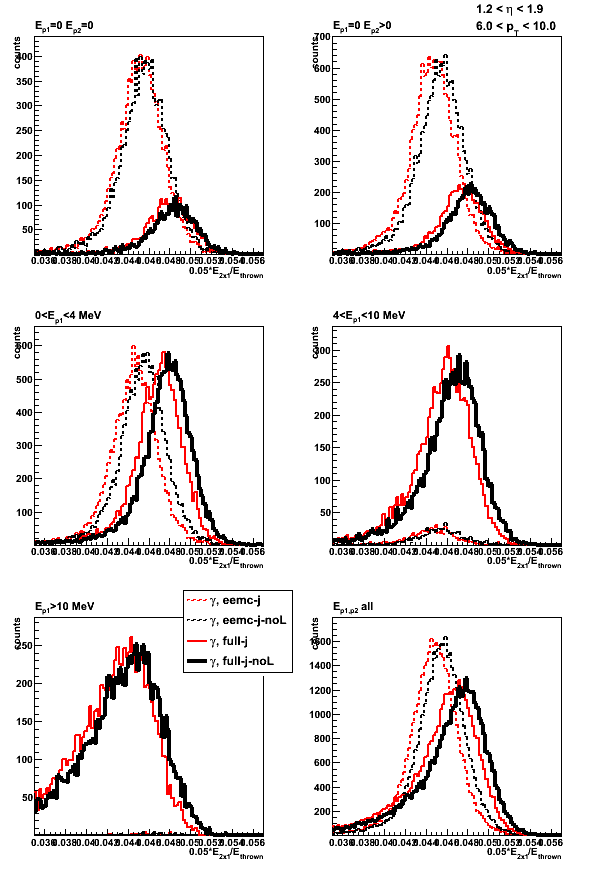

2009.08.27 fixed EEMC geometry: pre-shower sorted shower shapes & eta-meson comparison

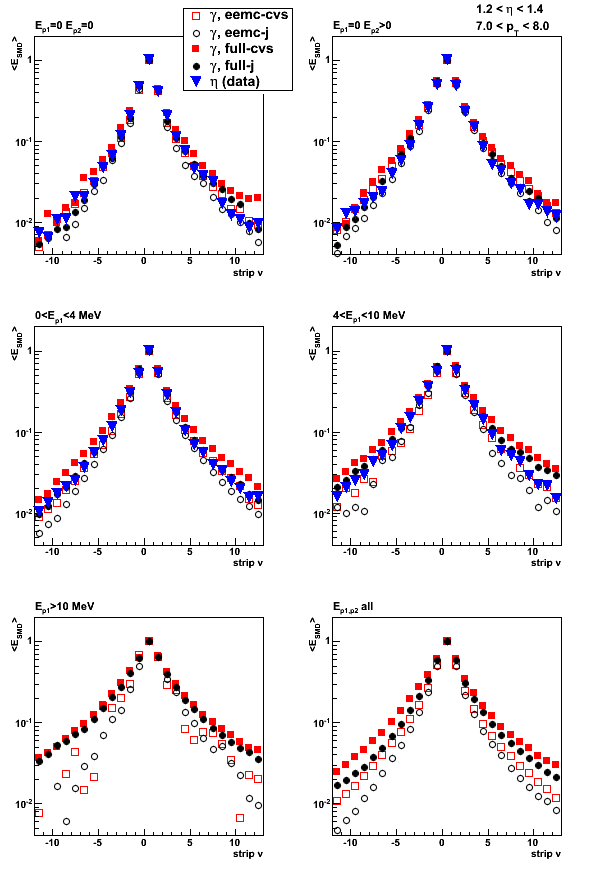

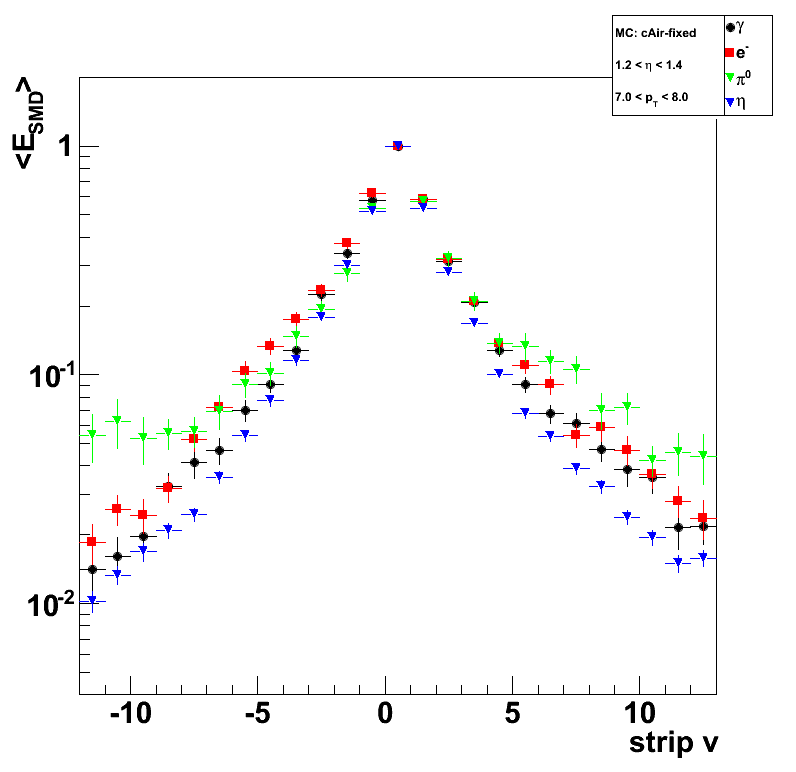

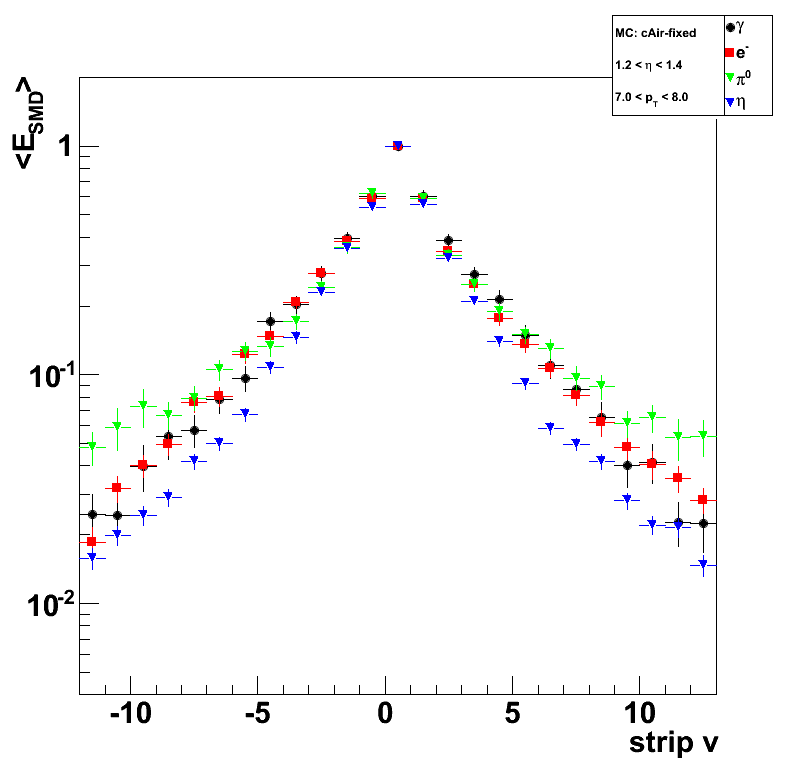

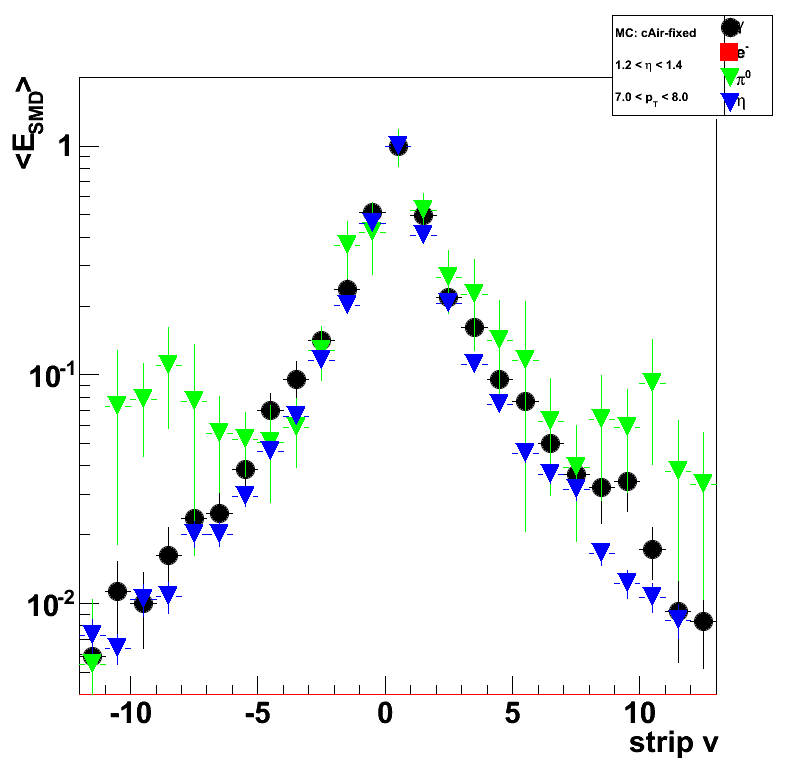

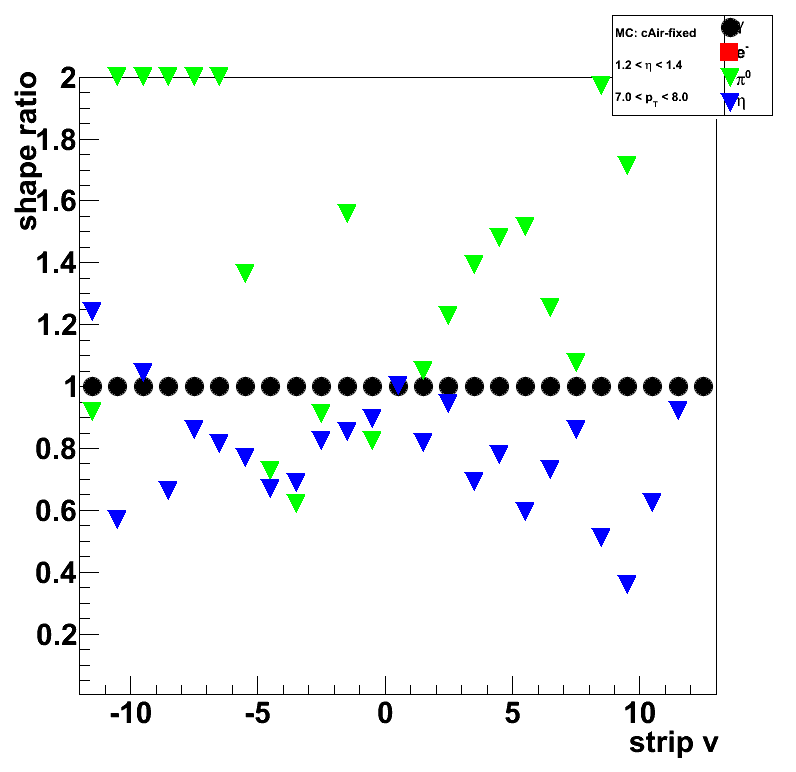

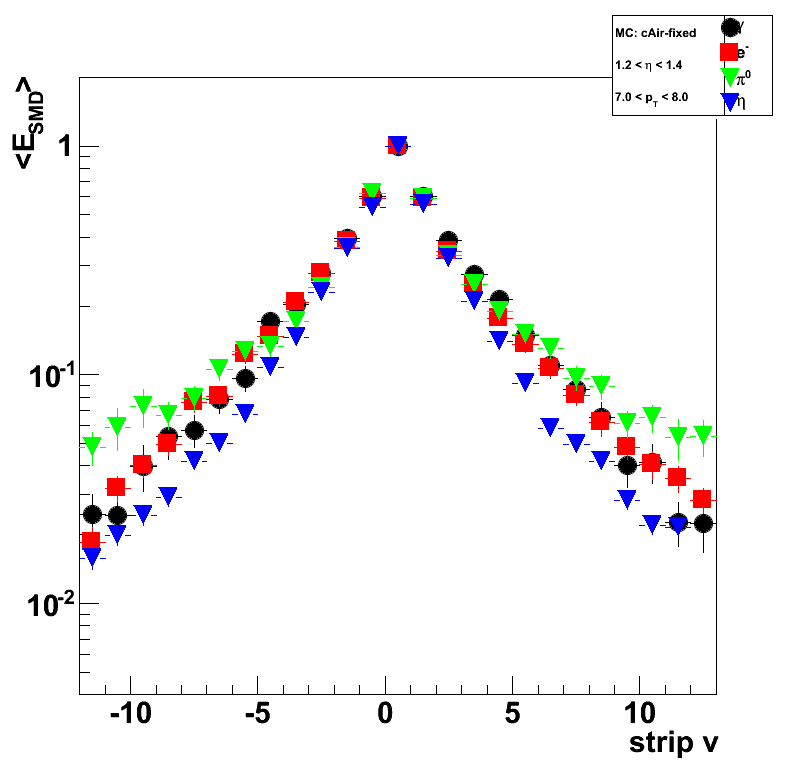

Test of corrected EEMC geometry: shower shapes (bug 1618)

Monte-Carlo setup is desribed here

- One particle per event (photons, electrons, and pions)

- Full STAR 2006 geometry.

In Kumac file: detp geom y2006g; gexec $STAR_LIB/geometry.so - Flat in eta (1.08-2.0), phi (0,2pi), and pt (3-30 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy (no EEMC SlowSimulator in chain)

what assumes fixed sampling fraction of 0.05 (5%) - Vertex z=0

- ~50K/per particle type

- Non-zero energy: 3 sigma above pedestal

Color coding:

- Black - photon (single particle/event MC)

- Red - electron (single particle/event MC)

- Green - neutral pion (single particle/event MC)

- Blue - photons from eta-meson decay (real data)

Single particle shower shape before (left) and after (right) EEMC cAir bug fixed

Single particle kinematic cuts: pt=7-8GeV, eta=1.2-1.4

Eta-meson shower shapes (blue) taken from Fig. 1 from here of this post

All shapes are normalized to 1 at peak (central strip).

Figure 1: Pre-shower bin 0: E_pre1=0; E_pre2=0

Figure 2: Pre-shower bin 1: E_pre1=0; E_pre2>0

Figure 3: Pre-shower bin 2: E_pre1>0; E_pre1<0.004

Figure 4: Pre-shower bin 3: E_pre1>0.004; E_pre1<0.01

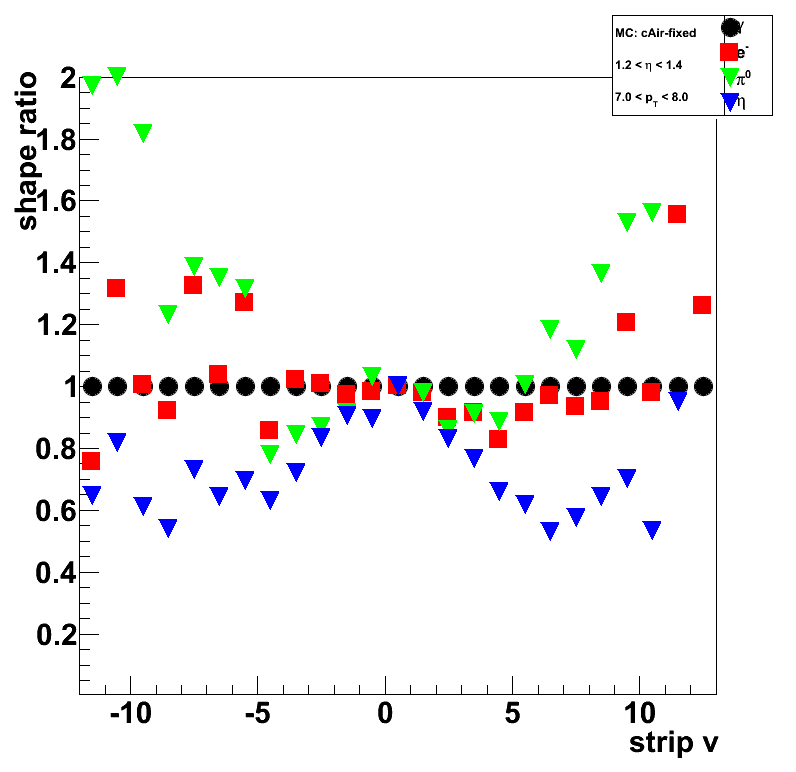

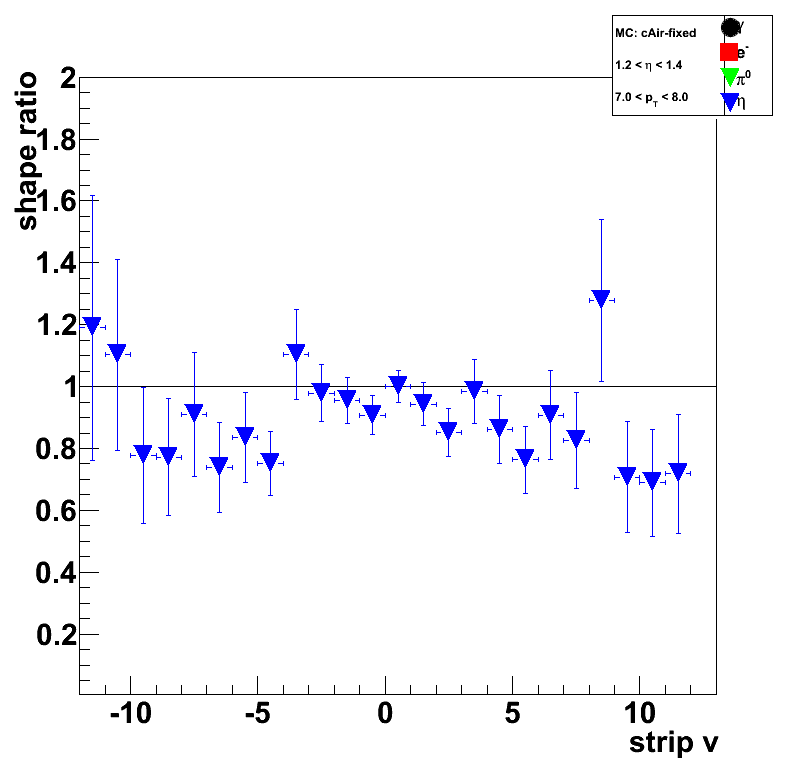

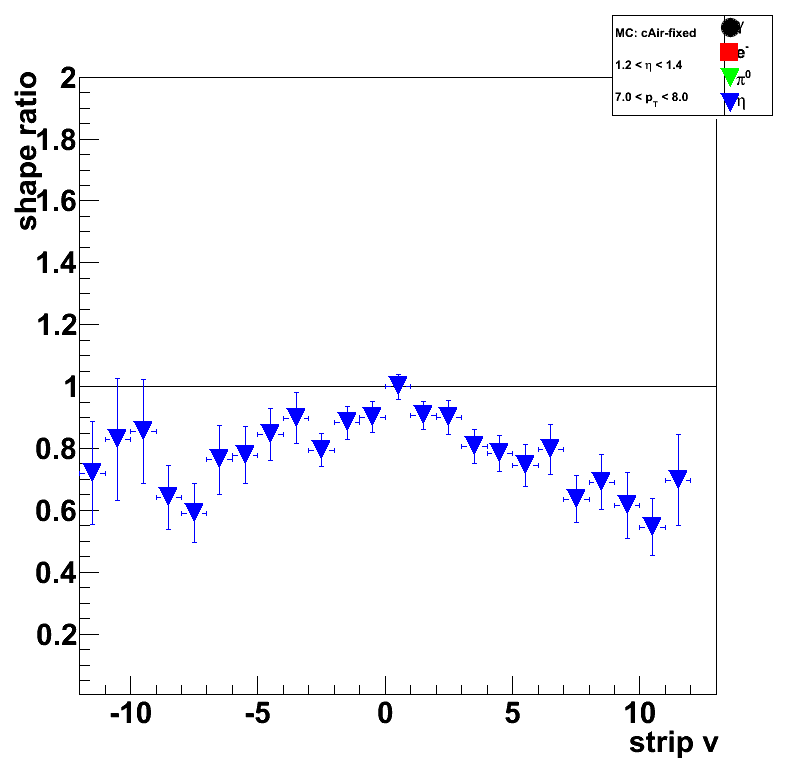

Shower shape ratios

Results only for corrected EEMC geometry

All shapes are divided by MC single-photon shower shape.

Figure 5a: Pre-shower bin 0: E_pre1=0; E_pre2=0

Figure 5b: Pre-shower bin 1: E_pre1=0; E_pre2>0

Figure 5c: Pre-shower bin 2: E_pre1>0; E_pre1<0.004

Figure 5d: Pre-shower bin 3: E_pre1>0.004; E_pre1<0.01

Figure 6: Single photon to eta-meson shape ratios only (with error bars):

Pre-shower bins 0 (upper-left),1 (upper-right),2 (lower-left), and 3 (lower-right)

Extracting gamma-jet cross section at forward rapidity from pp@200GeV collisions

Analysis overview

- Data samples, event selection, luminosity determination

- Isolating photon-jet events

- Transverse shower shape analysis

- Isolation cuts

- Cut optimization

- Trigger effects study

- Data to Monte-Carlo comparison/normalization and raw yields

- Acceptance/efficiency corrections

- Corrected yields

- Background subtraction

- Systematic uncertainties

- Comparison with theory

Data samples, event selection, luminosity determination

Real data, and signal/background Monte-Carlo samples:

-

pp@200GeV collisions, STAR produnctionLong.

Trigger: eemc-http-mb-L2gamma [id:137641] (L ~ 3.164 pb^1) -

Pythia prompt photon (signal) Monte-Carlo sample.

Filtered Prompt Photon p6410EemcGammaFilter.

Partonic pt range 2-25 GeV. -

Pythia 2->2 hard QCD processes (background) Monte-Carlo sample.

Filtered QCD p6410EemcGammaFilter.

Partonic pt range 2-25 GeV.

Isolating photon-jet events

- Shower shape analysis

- Isolation cuts

- Energy clustering (2x1 vs. 2x2 vs. 3x3, cluster energy vs. rapidity)

- Charge particle veto

- photon and jet pt balance

- Tower multiplicity

- Cut optimization with LDA.

Input variables (list can be expanded):- Energy fraction in 3x3 cluster within a r=0.7 radius, E_3x3/E_0.7

- Photon-jet pt balance, [pt_gamma-pt_jet]/pt_gamma

- Number of charge tracks within r=0.7 around gamma candidate

- Number of Endcap towers fired within r=0.7 around gamma candidate

- Number of Barrel towers fired within r=0.7 around gamma candidate

- Shower shape analysis: distance to 80% cut line

- Energy fraction in E_2x1 and E_2x2 witin E_3x3

- Energy in post-shower layer under 3x3 tower patch

- Tower energy in 3x3 patch

- SMD-u/v energy in 25 central strips

- SMD-u/v peak energy (in 5 central strips)

Trigger effects study

No studies yet

- Trigger effects vs pt

- Trigger effects vs eta

- What else?

Data to Monte-Carlo comparison/normalization and raw yields

- Overall data to MC normalization based on vertex z distribution

- Data to MC comparison of raw yield in various detector subsystems

- Uncorrected yields optimized with different efficiency/purity

Acceptance/efficiency corrections

No studies yet

- What needs to be studied for acceptance/efficiency effects?

- Converting reconstructed photon (jet) energy/momentum to the true one

- Reconstruction efficiency vs. rapidity, pt, etc

Corrected yields

No studies yet

- Produce acceptance/efficiency corrected yields

Background subtraction

No studies yet

- Statistical background subtraction based on Pythia+GEANT Monte-Carlo

- Estimate systematic uncertainties due to background subtraction

Systematic uncertainties

No studies yet

- Calorimeter energy resolution

- Trigger bias

- Other effects

Comparison with theory

No comparison yet

- Request for pQCD calculations at forward rapidity

09 Sep

September 2009 posts

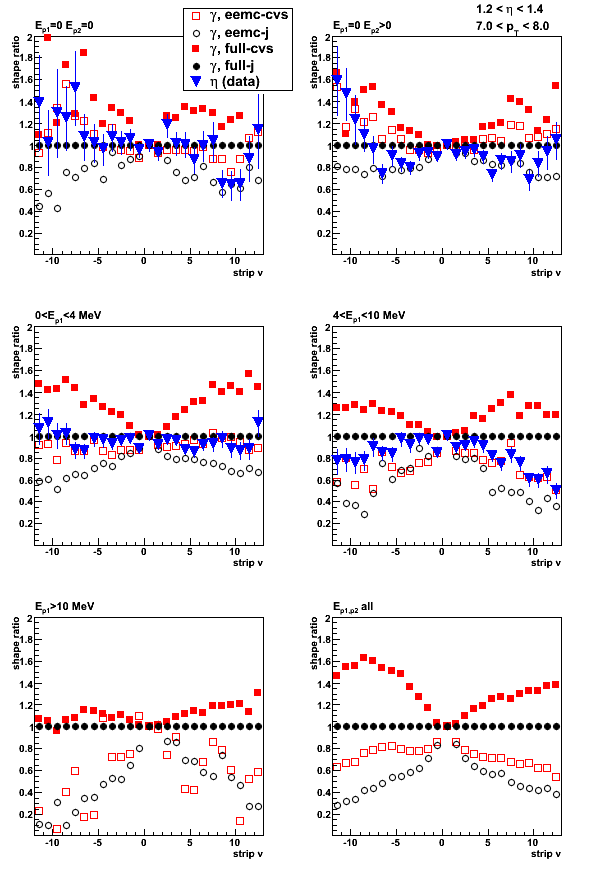

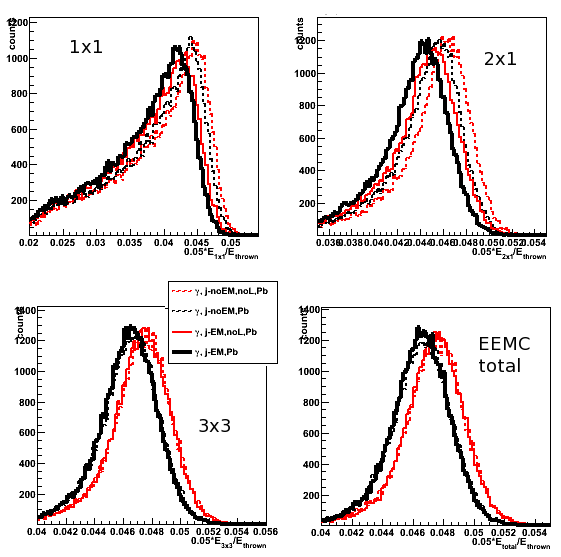

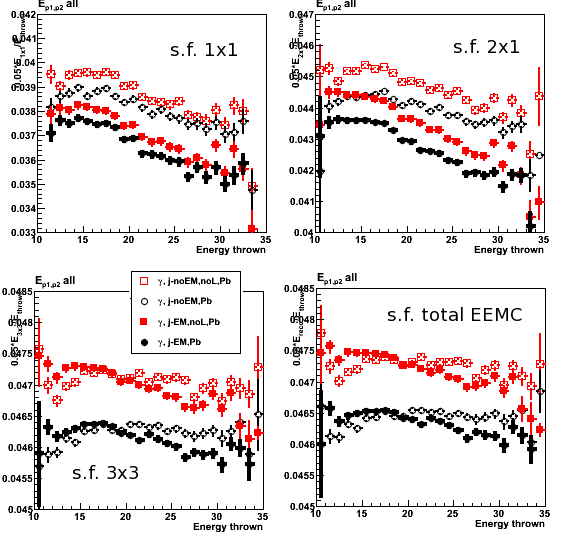

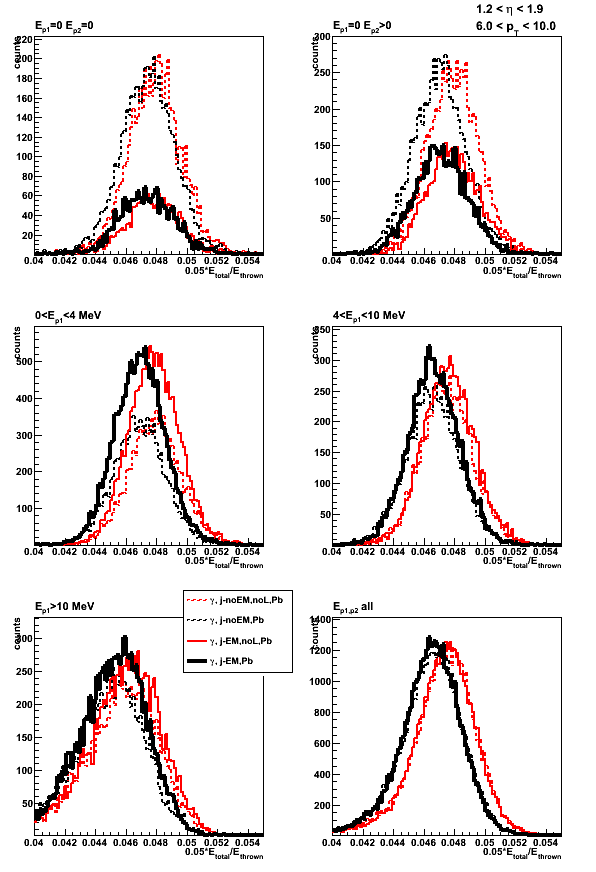

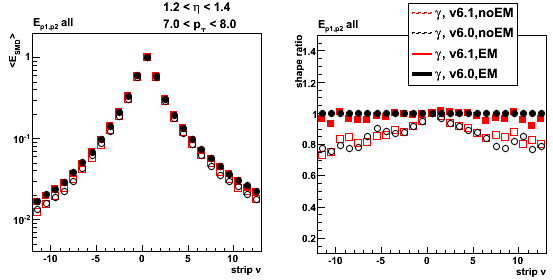

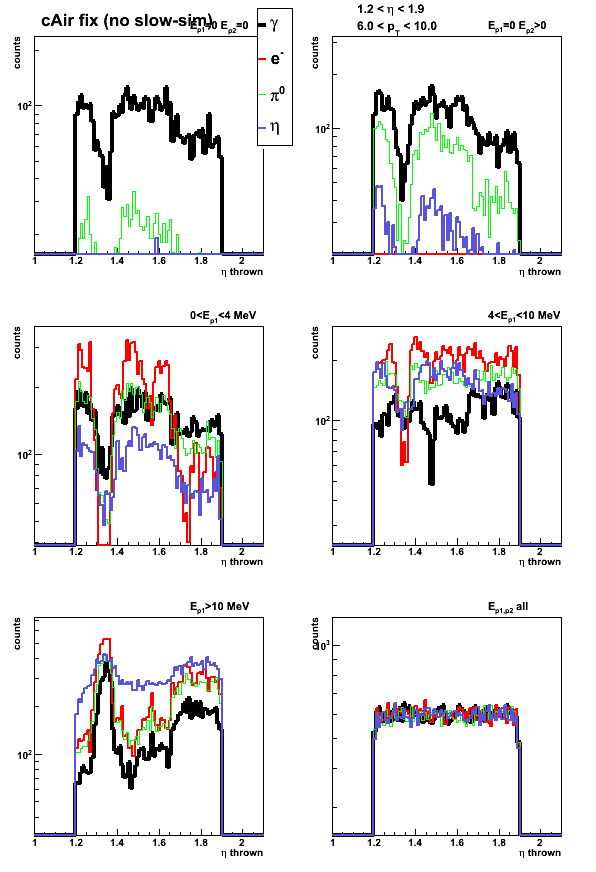

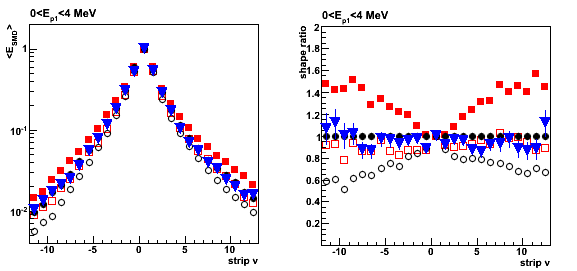

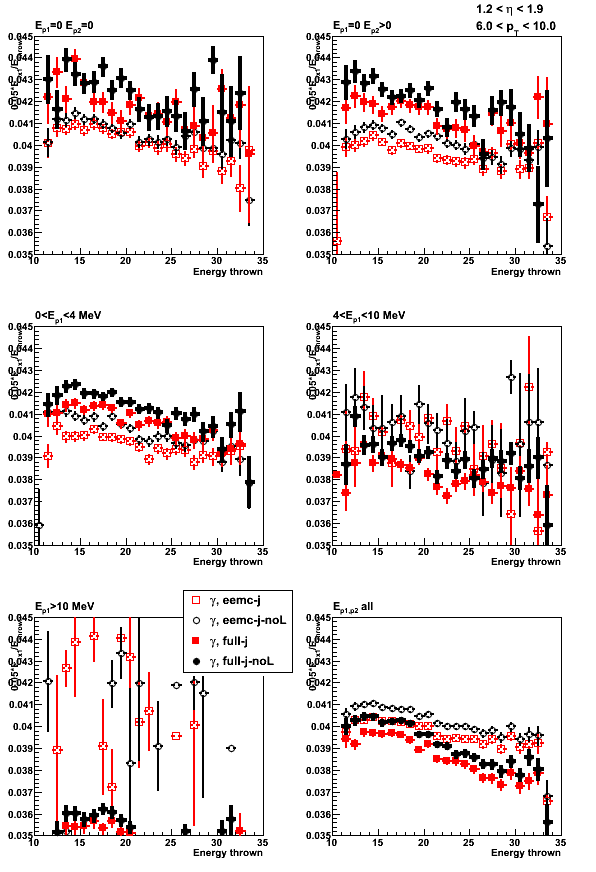

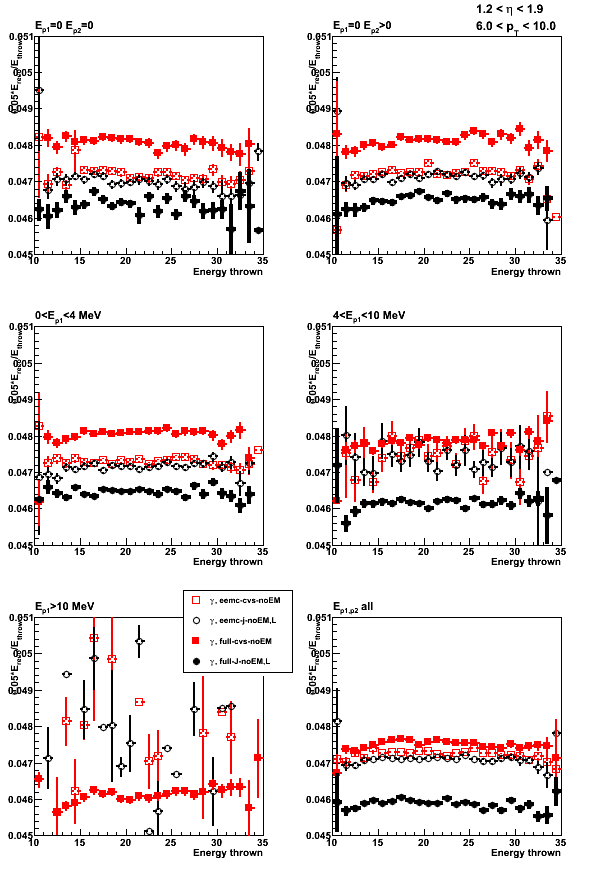

2009.09.04 Test of corrected EEMC geometry: SVT, slow-simulator on/off, pre-shower migration

Test of corrected EEMC geometry: shower shapes (bug 1618)

Monte-Carlo setup:

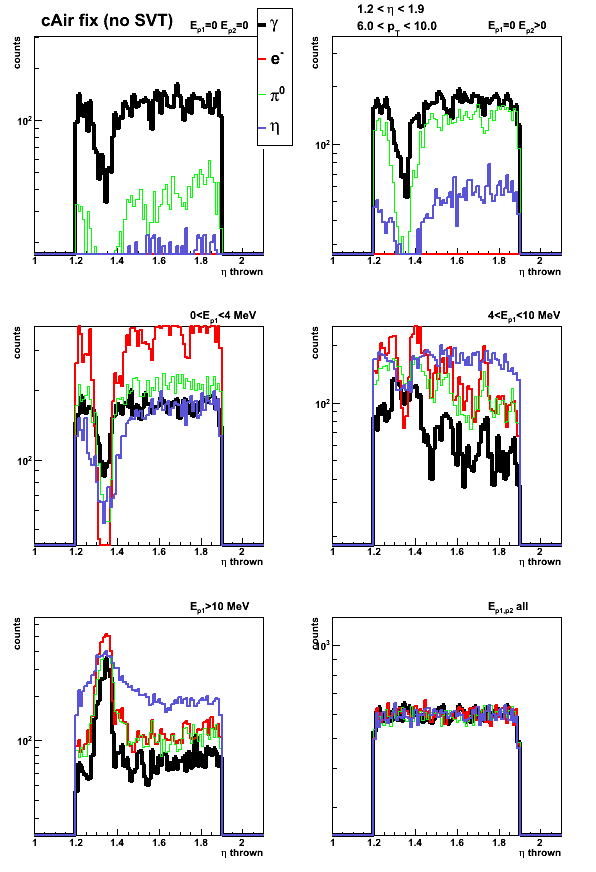

- One particle per event (photons, electrons, pions, and eta-meson)

- Full STAR 2006 geometry (with/without SVT)

In Kumac file: detp geom y2006g; gexec $STAR_LIB/geometry.so (remove SVT with SVTT_OFF option) - Throw particles flat in eta (1.08, 2.0), phi (0, 2pi), and pt (6-10 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy

(with/without EEMC SlowSimulator in chain) - Vertex z=0

- ~50K/per particle type

- Non-zero energy: 3 sigma above pedestal

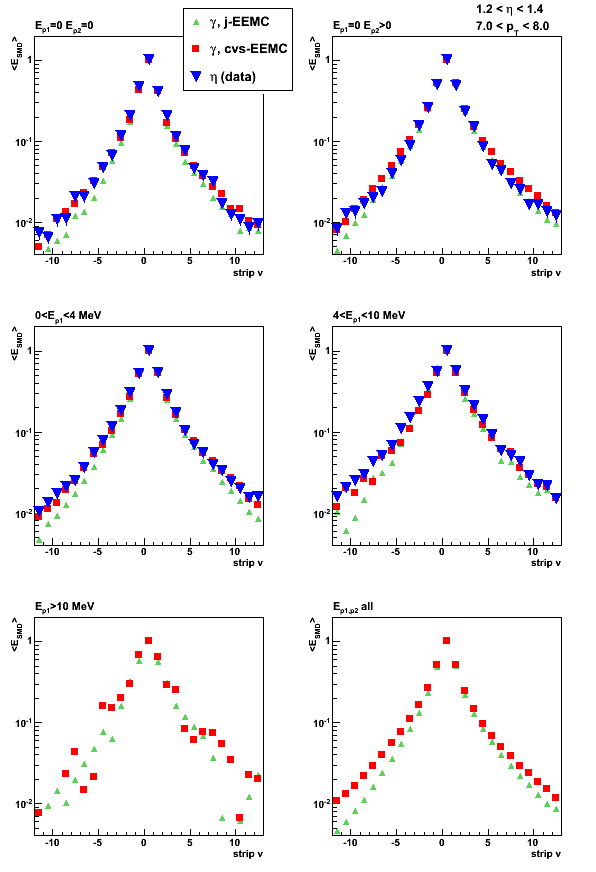

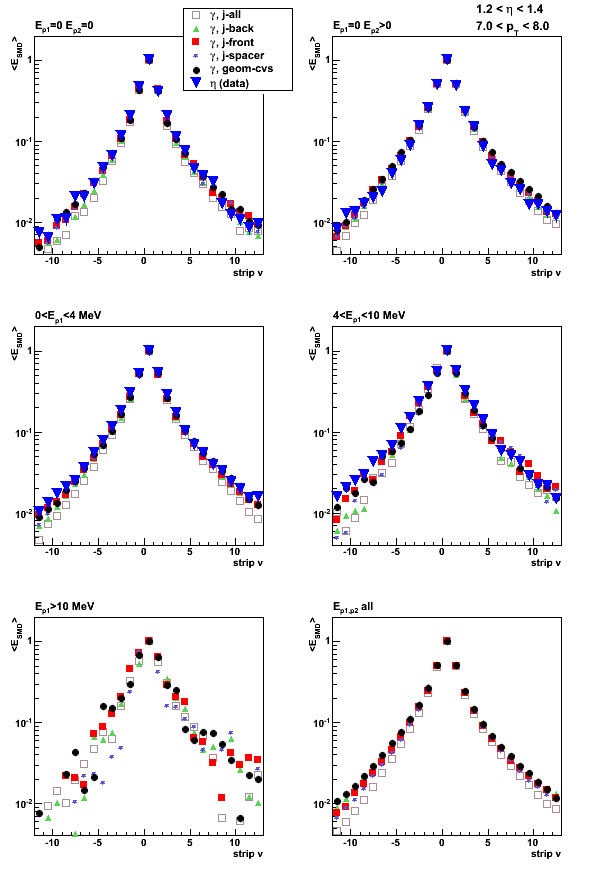

Color coding:

- Photon (single particle MC)

- Electron (single particle MC)

- Neutral pion (single particle MC)

- Eta-meson (single particle MC)

- Eta-meson [pp2006 data] (single photons from eta-meson decay)

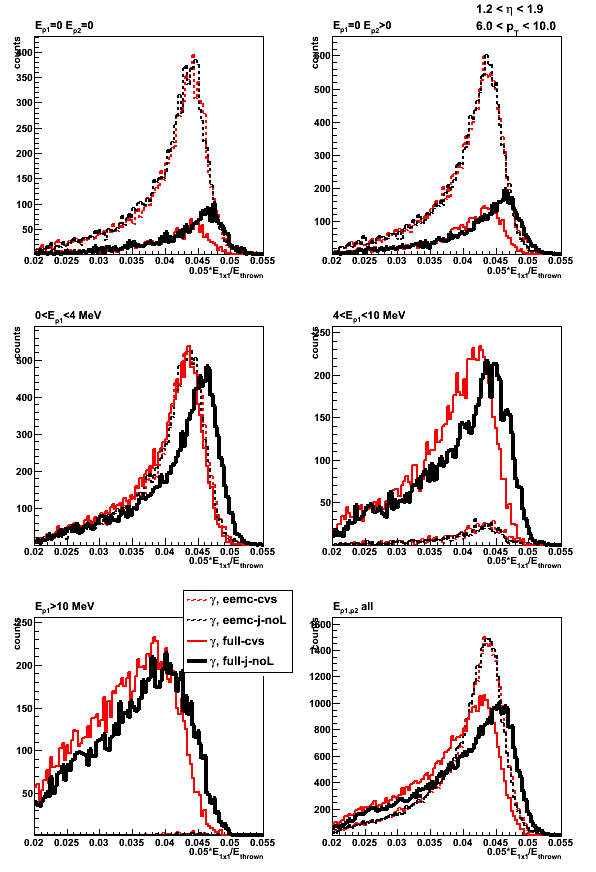

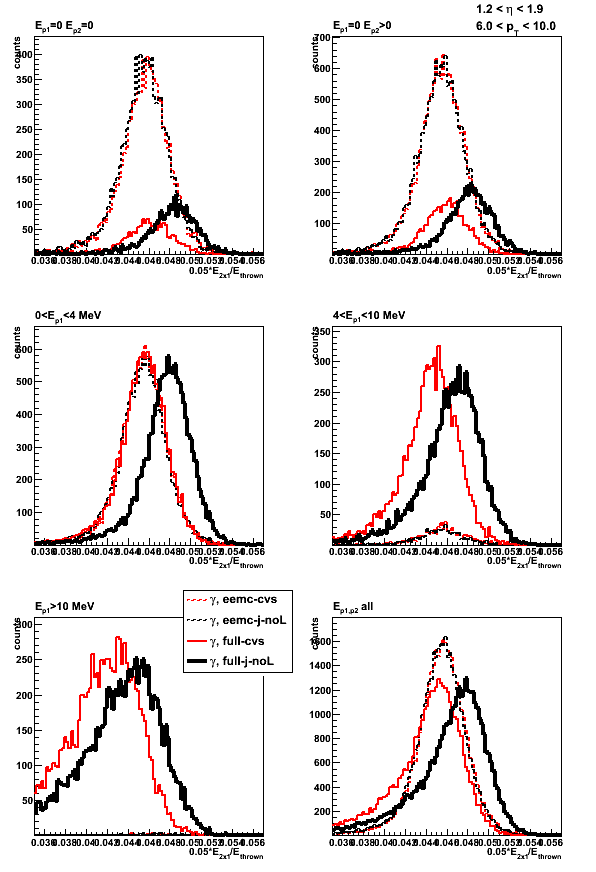

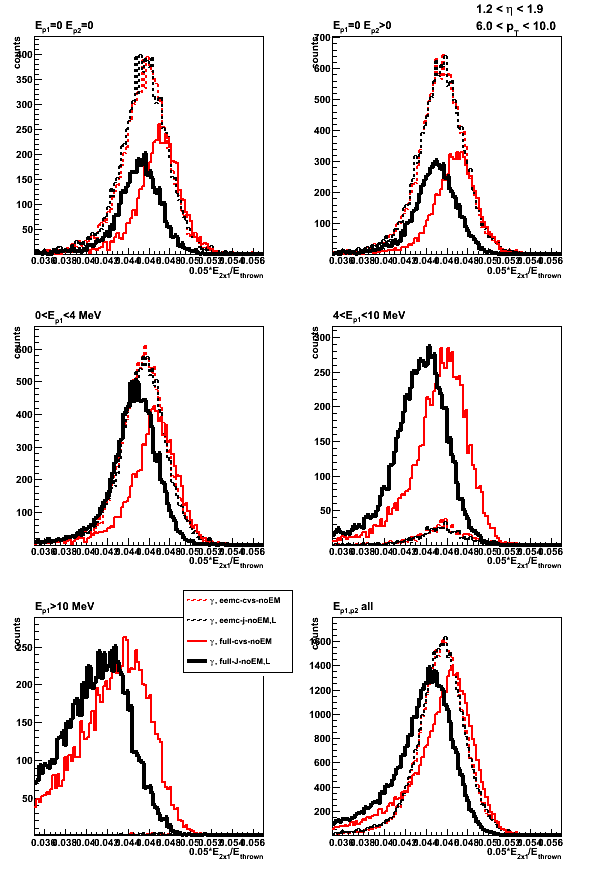

Pre-shower bins:

- Ep1 = 0, Ep2 = 0 (no energy in both EEMC pre-shower layers)

- Ep1 = 0, Ep2 > 0

- 0 < Ep1 < 4 MeV

- 4 < Ep1 < 10 MeV

- Ep1 > 10 MeV

- All pre-shower bins combined

Ep1/Ep2 is the energy deposited in the 1st/2nd EEMC pre-shower layer.

For a single particle MC it is a sum over

all pre-shower tiles in the EEMC with energy of 3 sigma above pedestal.

For eta-meson from pp2006 data the sum is over 3x3 tower patch

Shower shapes

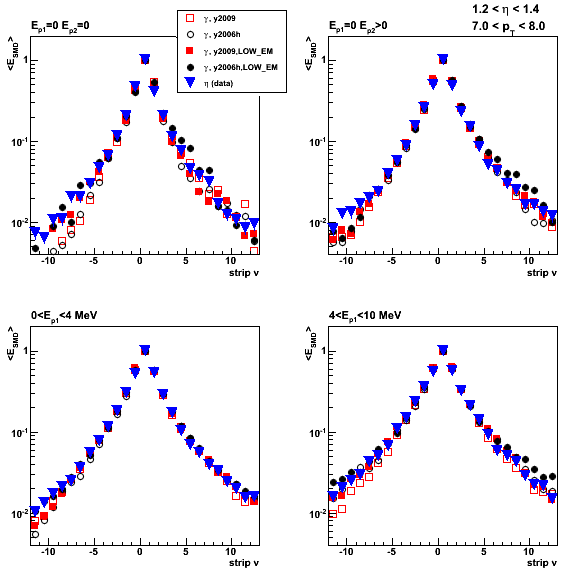

Single particle kinematic cuts: pt=7-8GeV, eta=1.2-1.4

Eta-meson shower shapes (blue) taken from Fig. 1 from here of this post

All shapes are normalized to 1 at peak (central strip)

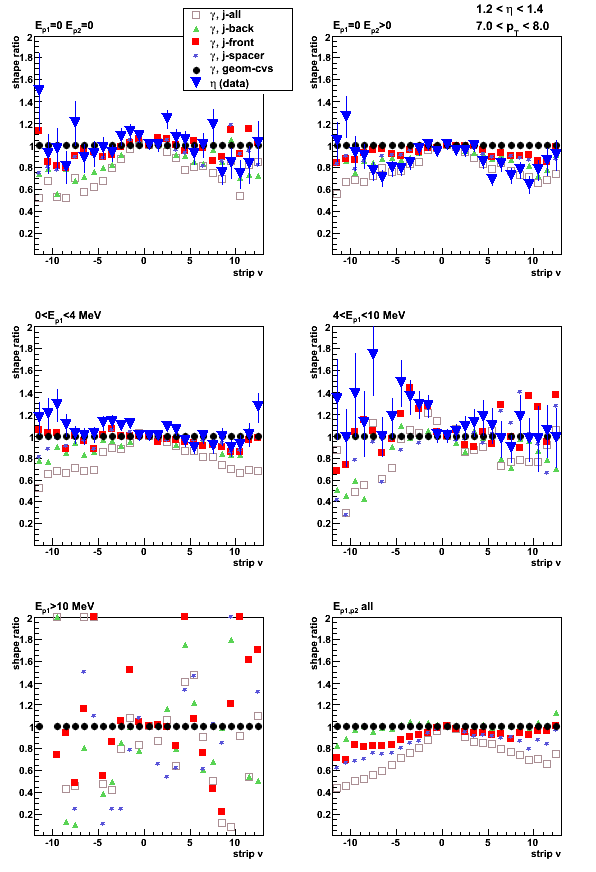

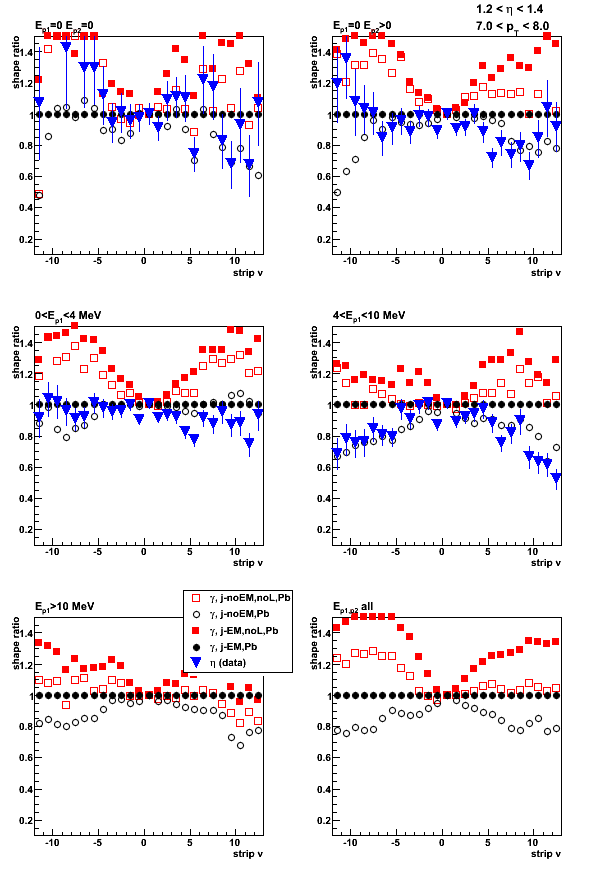

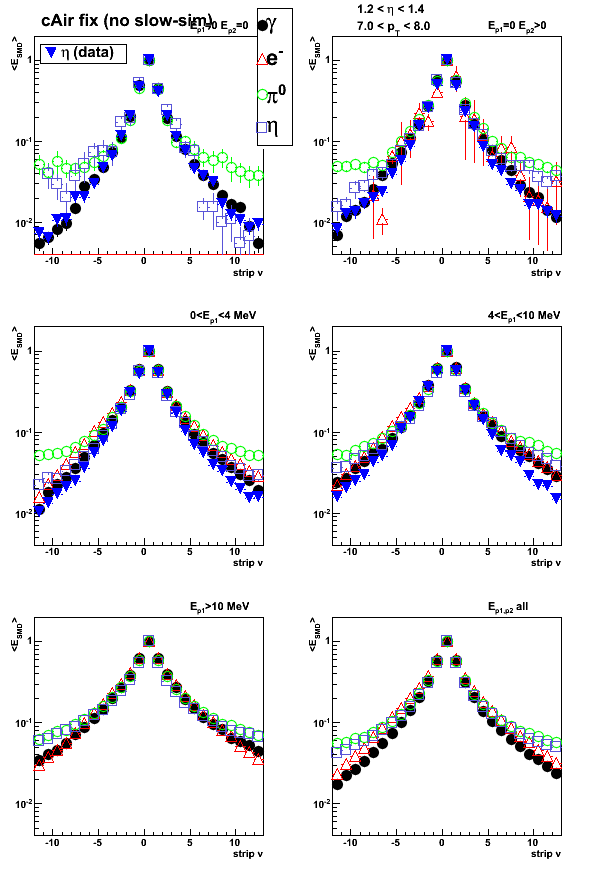

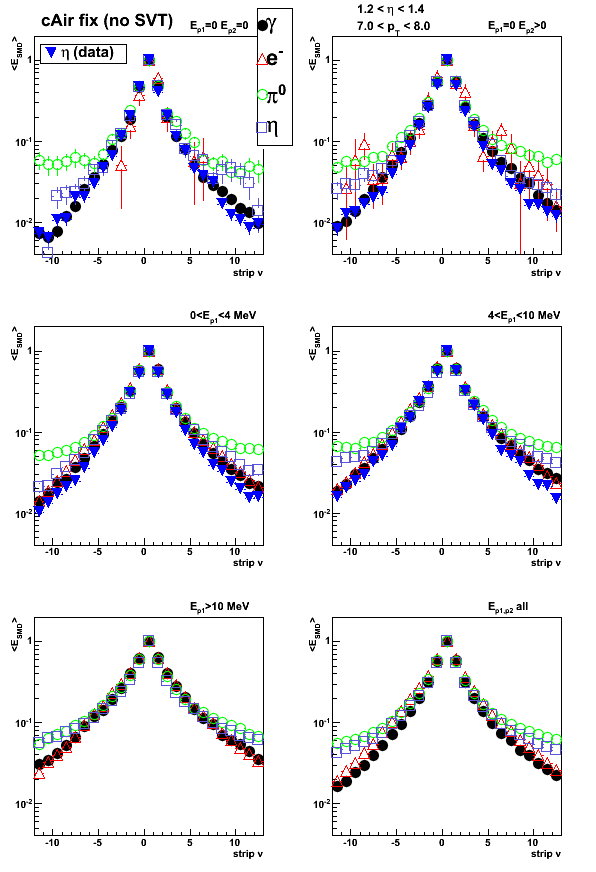

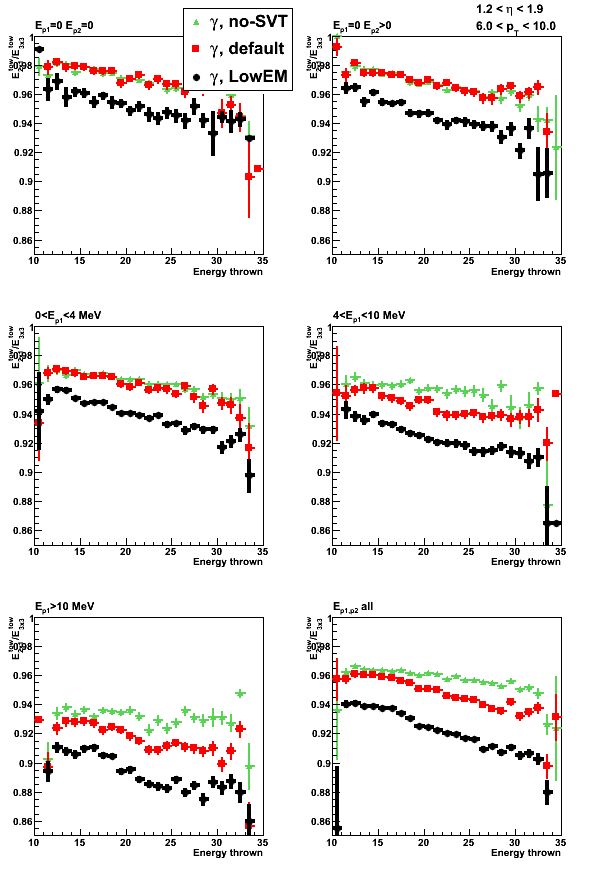

Figure 1: Shower shape sorted by pre-shower conditions.

cAir-Fixed EEMC geometry (NO slow simulator, WITH SVT)

Ratio plot

Figure 2: Shower shape sorted by pre-shower conditions.

cAir-Fixed EEMC geometry (NO slow simulator, NO SVT)

Ratio plot

Figure 3: Shower shape sorted by pre-shower conditions.

cAir-Fixed EEMC geometry (WITH slow simulator, WITH SVT)

Ratio plot

Figure 4: Shower shape sorted by pre-shower conditions.

Old cAir-bug EEMC geometry (NO slow simulator, WITH SVT)

Click here to see the plot

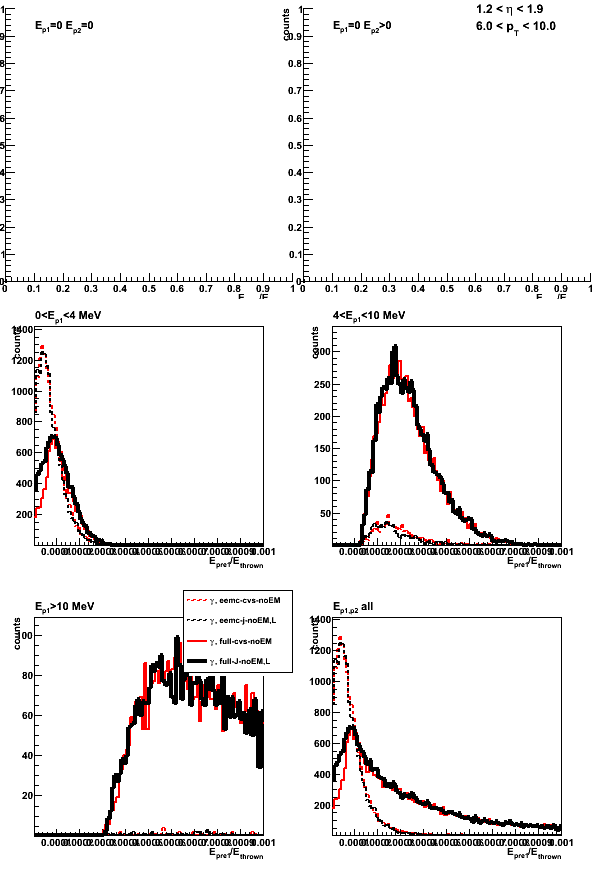

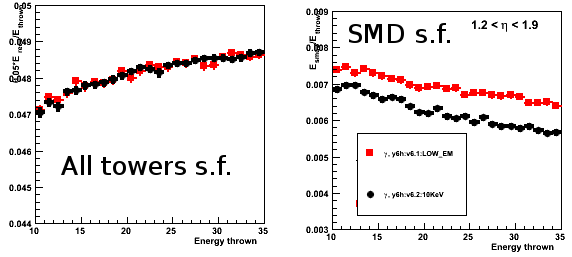

Pre-shower migration with/without SVT

Starting with a fixed (50K events) for each type of particle.

Change in number of counts for a given pre-shower bin

with different detector configuration shows pre-shower migration

Figure 5: Pre-shower migration.

cAir-Fixed EEMC geometry (WITH SVT)

Figure 6: Pre-shower migration.

cAir-Fixed EEMC geometry (WITHOUT SVT)

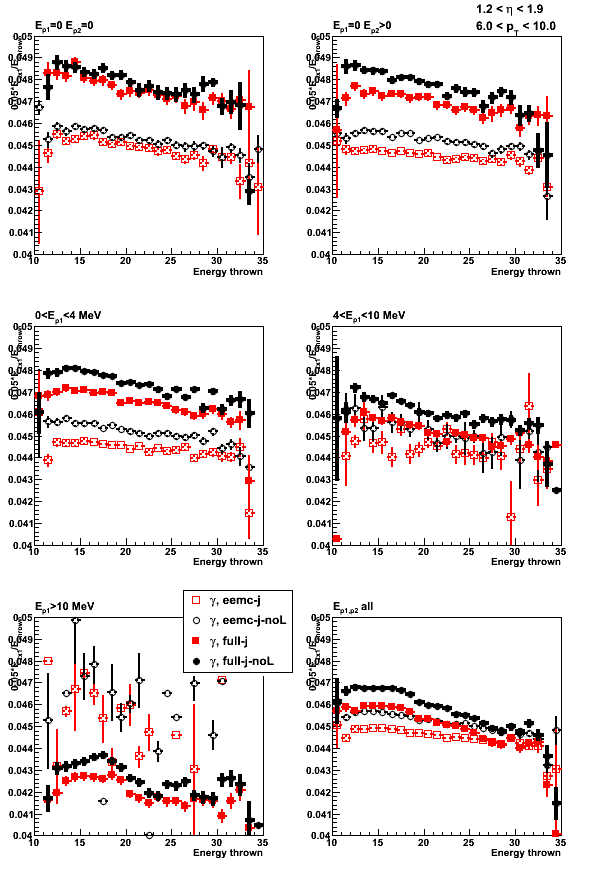

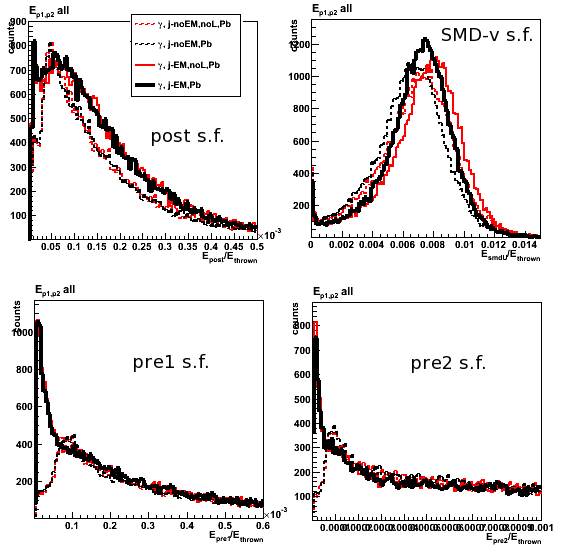

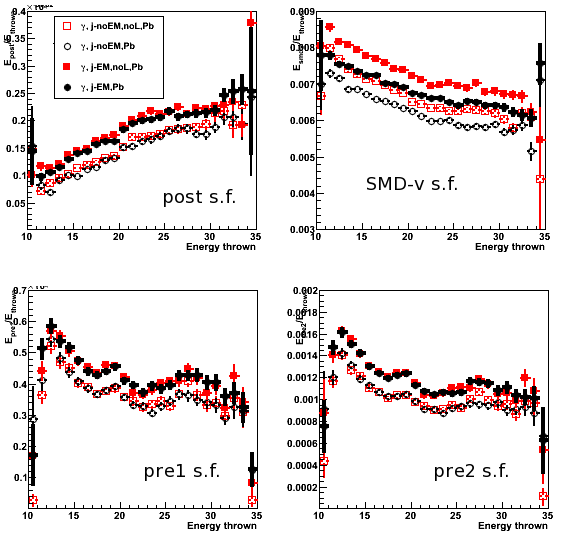

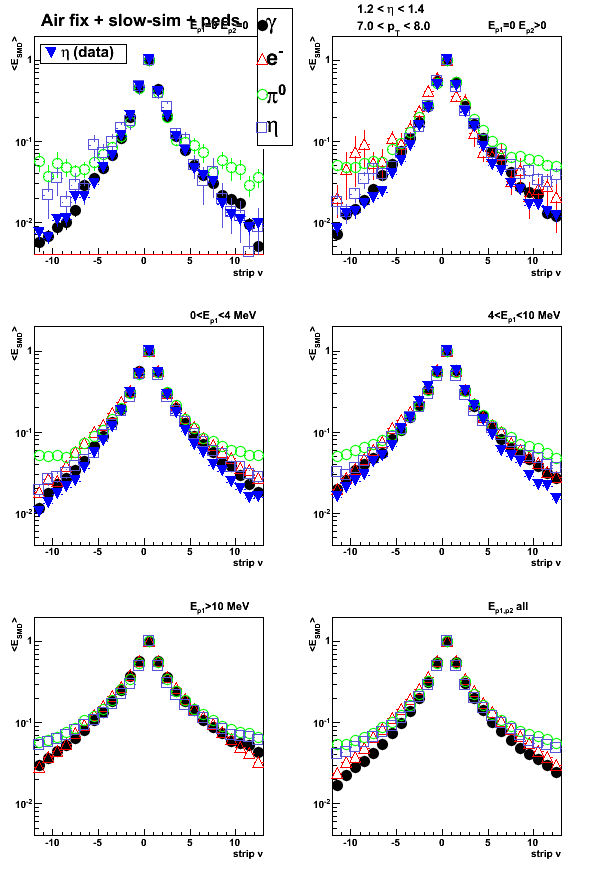

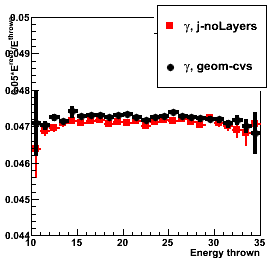

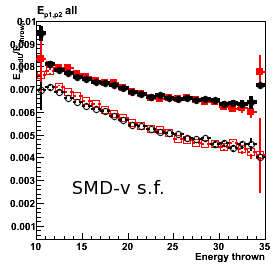

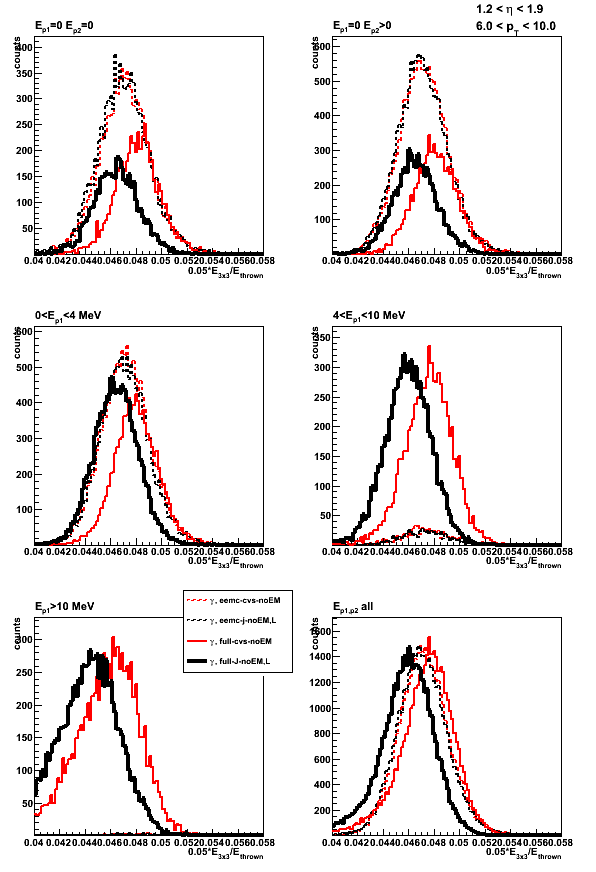

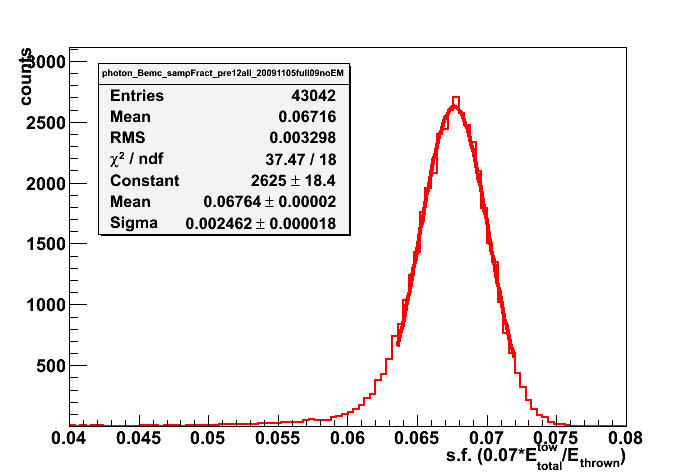

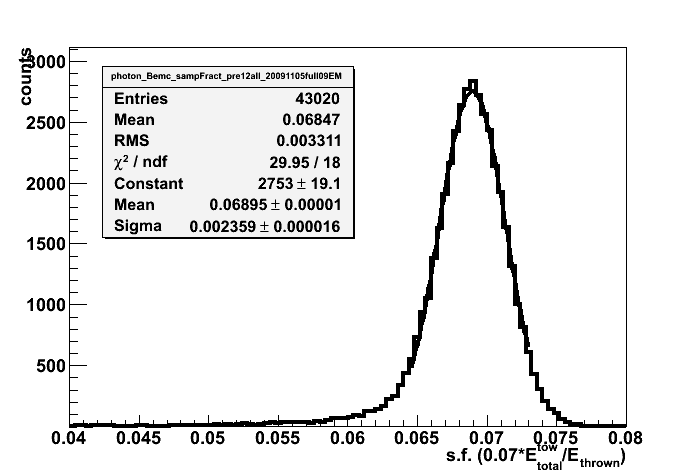

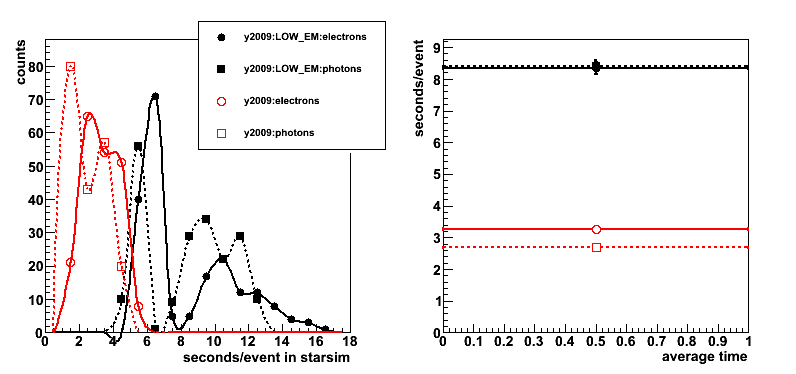

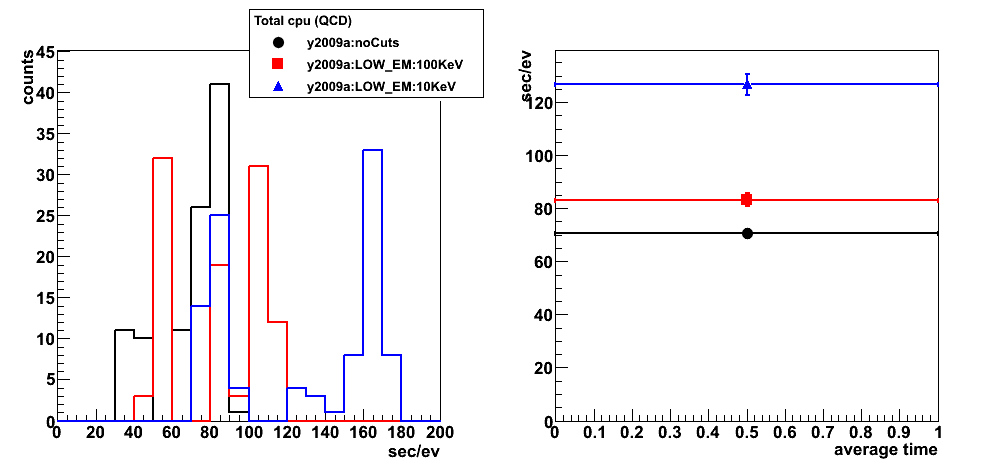

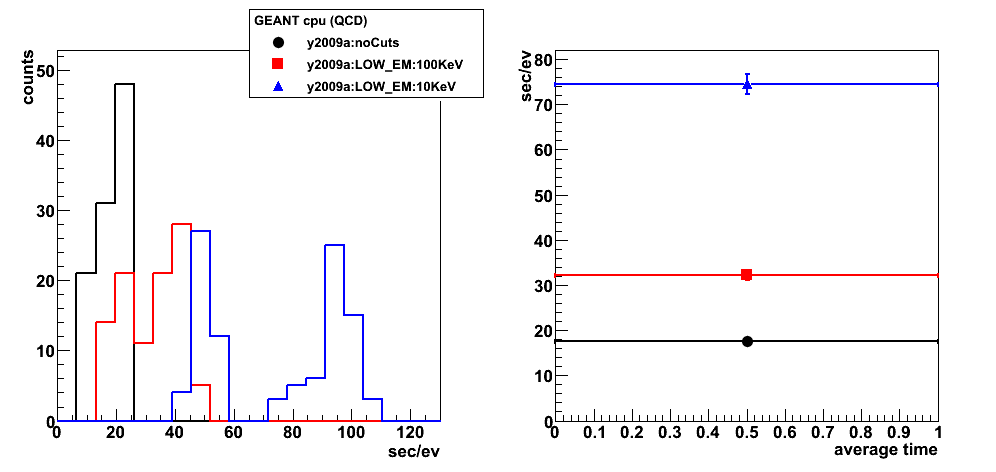

Sampling fraction with/without Slow-simulator

Figure 7: Sampling fraction (0.05 E_reco / E_thrown).

cAir-Fixed EEMC geometry (WITHOUT Slow-simulator)

Figure 8: Sampling fraction (0.05 E_reco / E_thrown).

cAir-Fixed EEMC geometry (WITH Slow-simulator)

Slow simulator introduce some non-linearity in the sampling fraction

Figure 9: Sampling fraction (0.05 E_reco / E_thrown).

cAir-Fixed EEMC geometry (WITHOUT SVT, WITHOUT Slow-simulator)

Click here to see the plot

Figure 10: Sampling fraction (0.05 E_reco / E_thrown).

Old cAir-bug EEMC geometry (NO slow simulator, WITH SVT)

Click here to see the plot

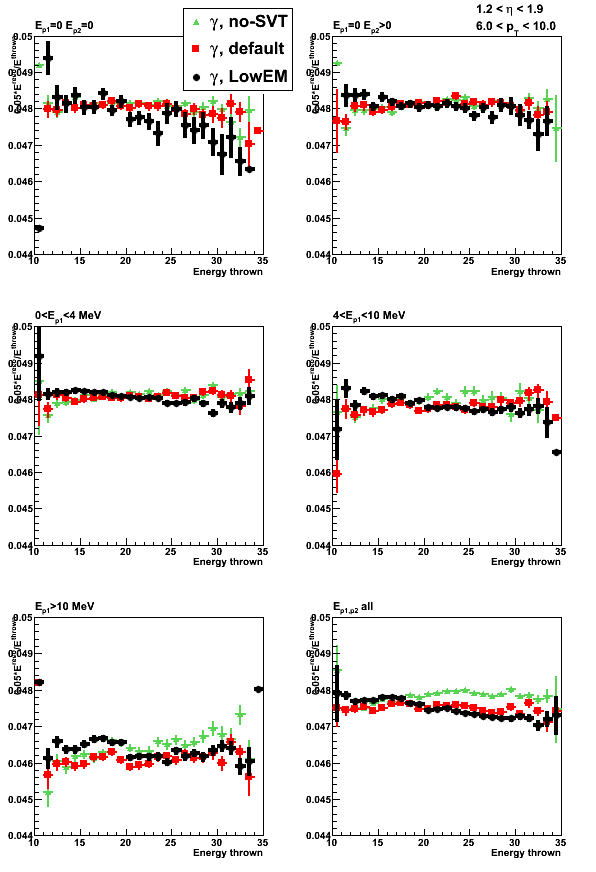

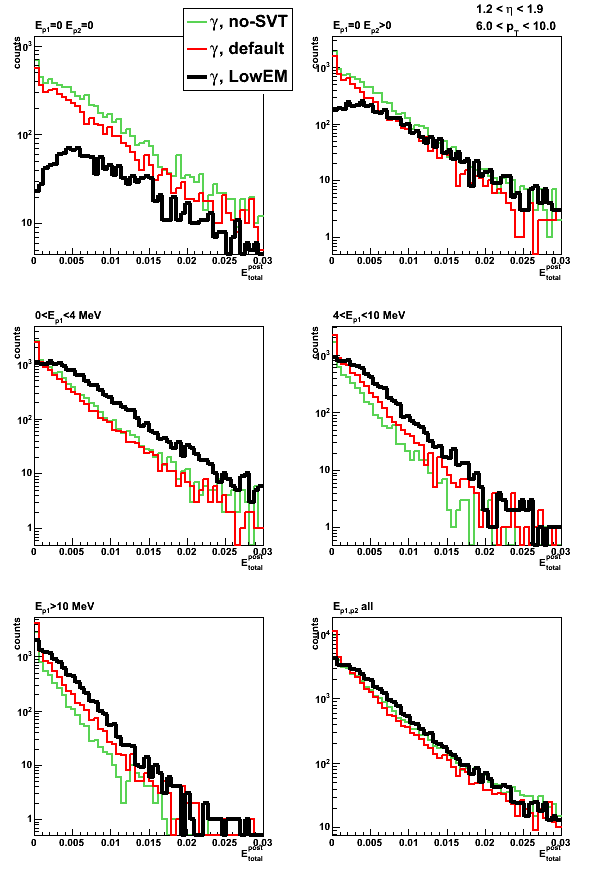

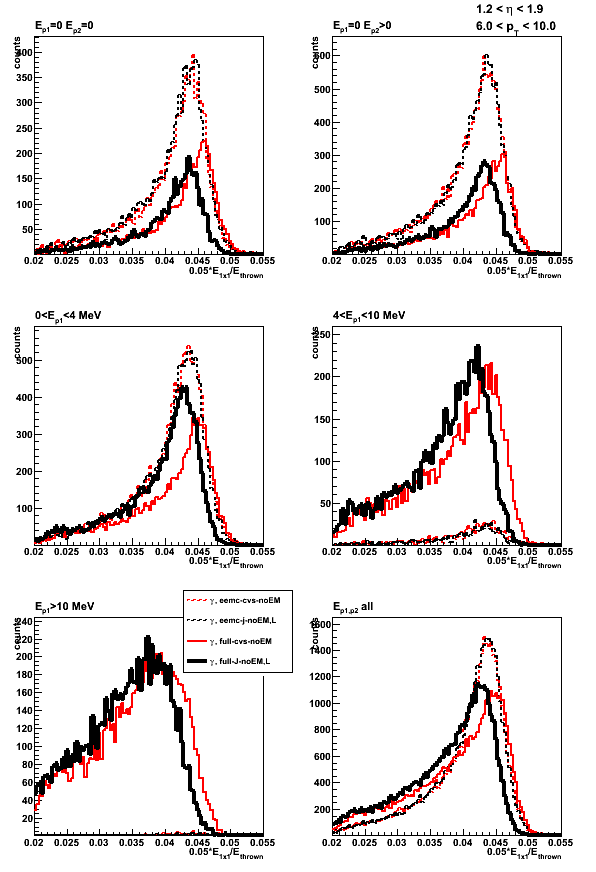

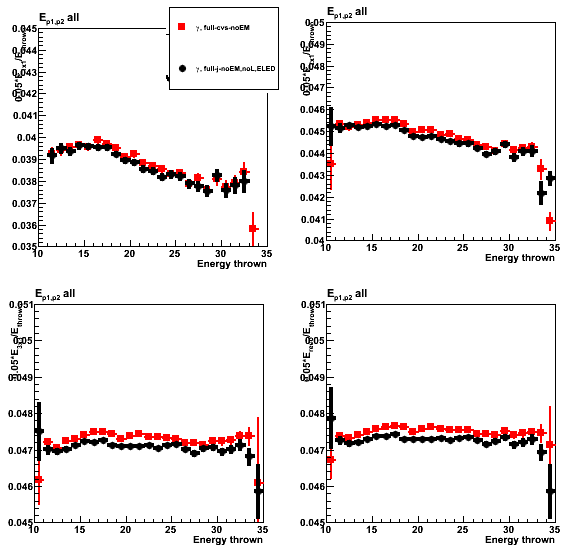

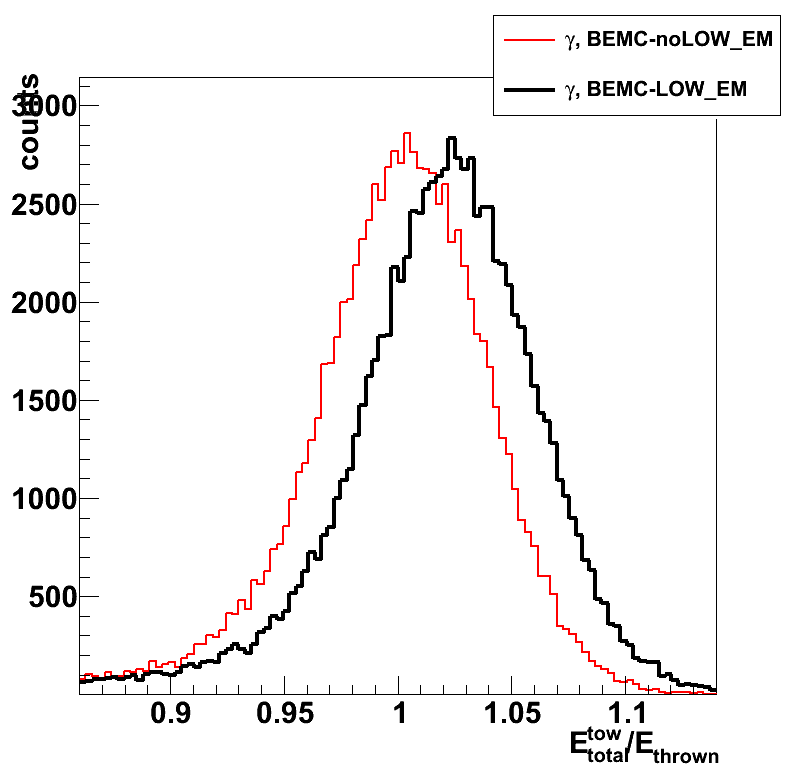

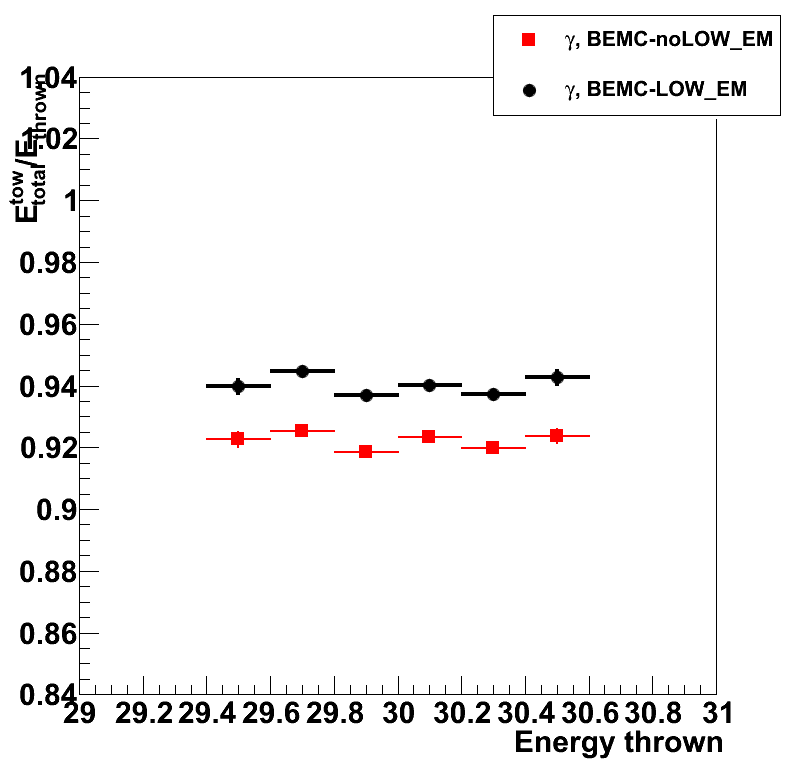

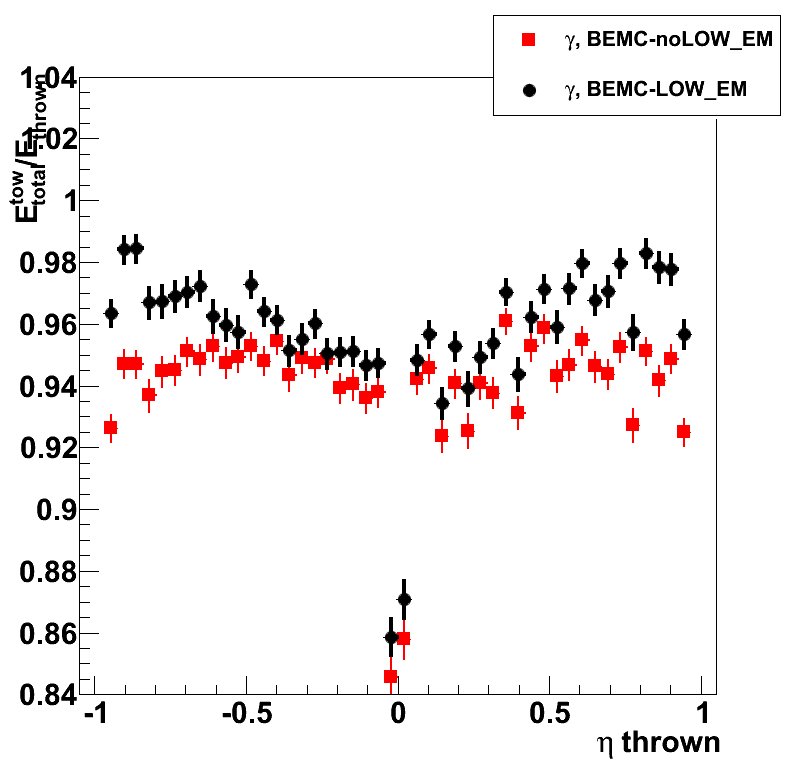

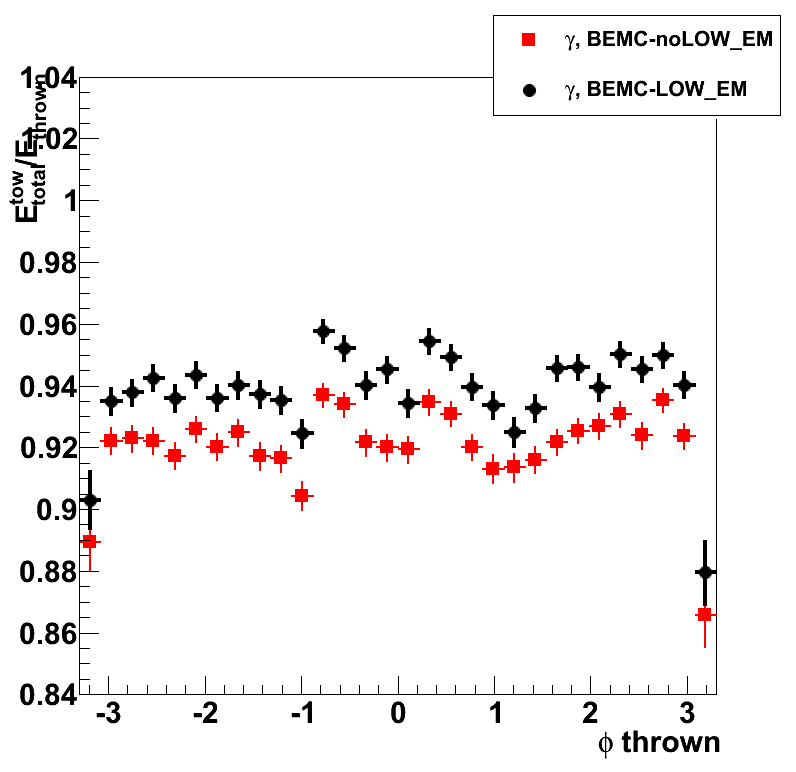

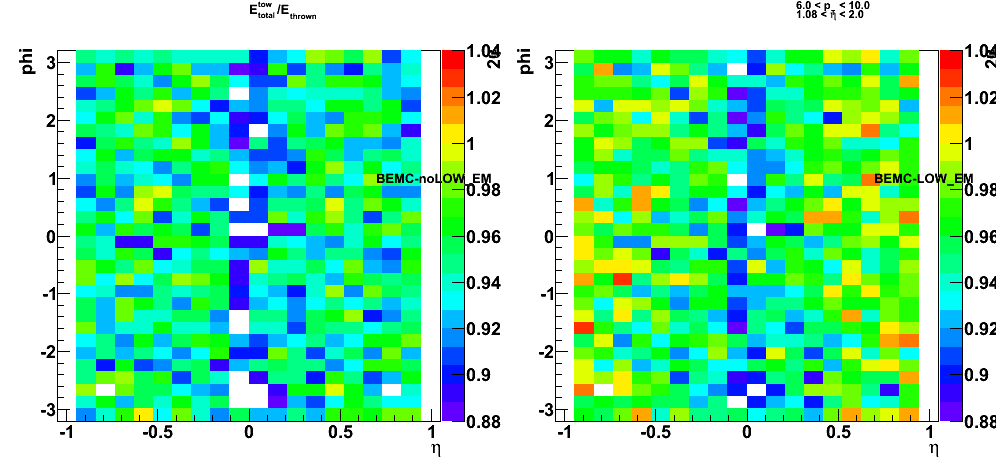

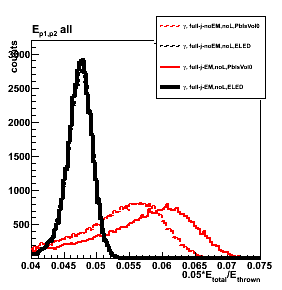

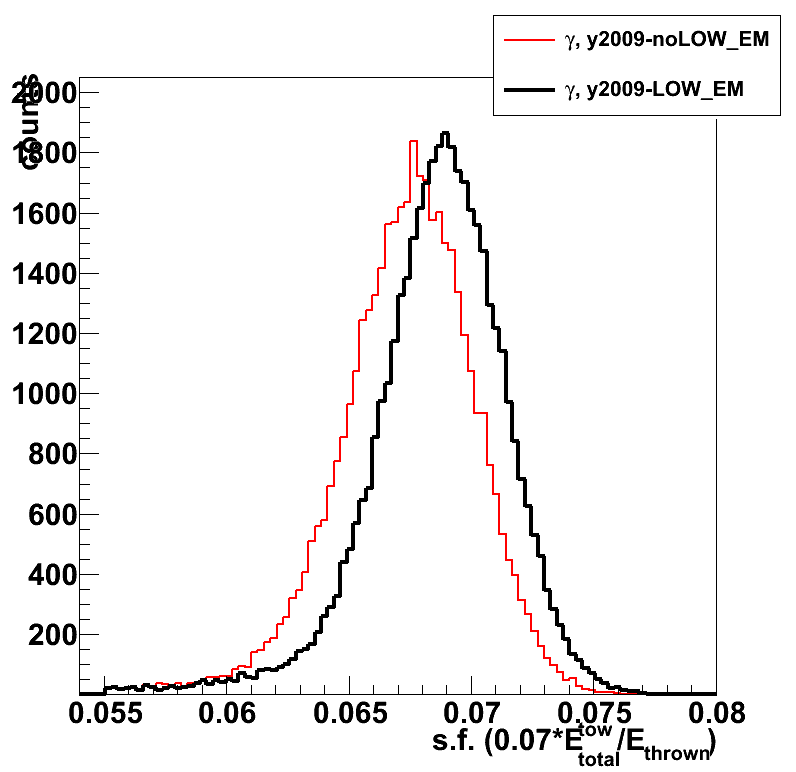

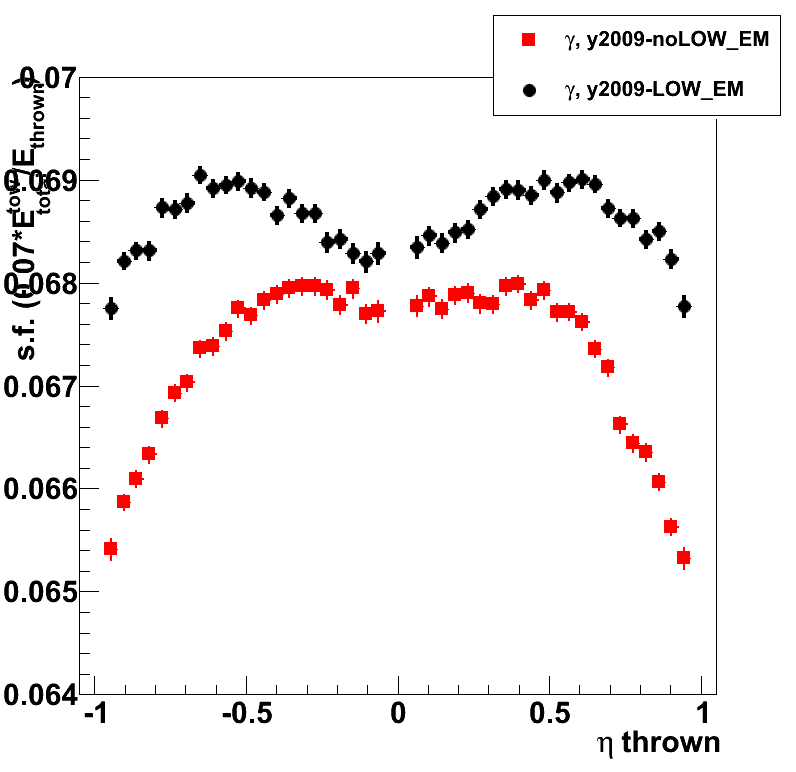

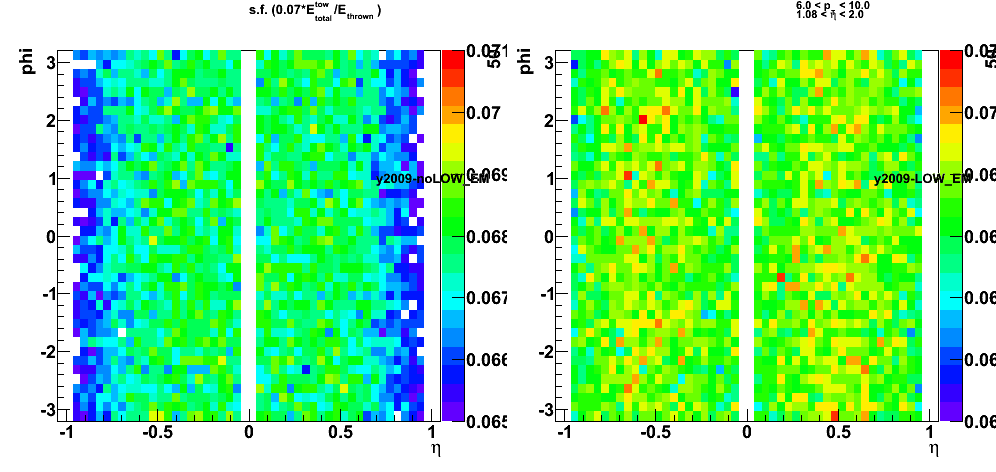

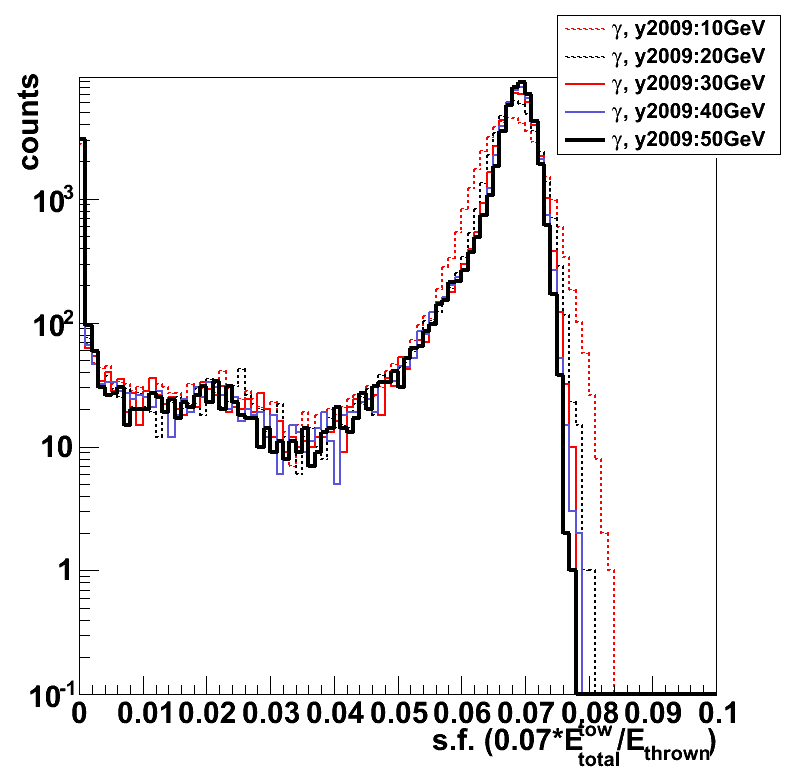

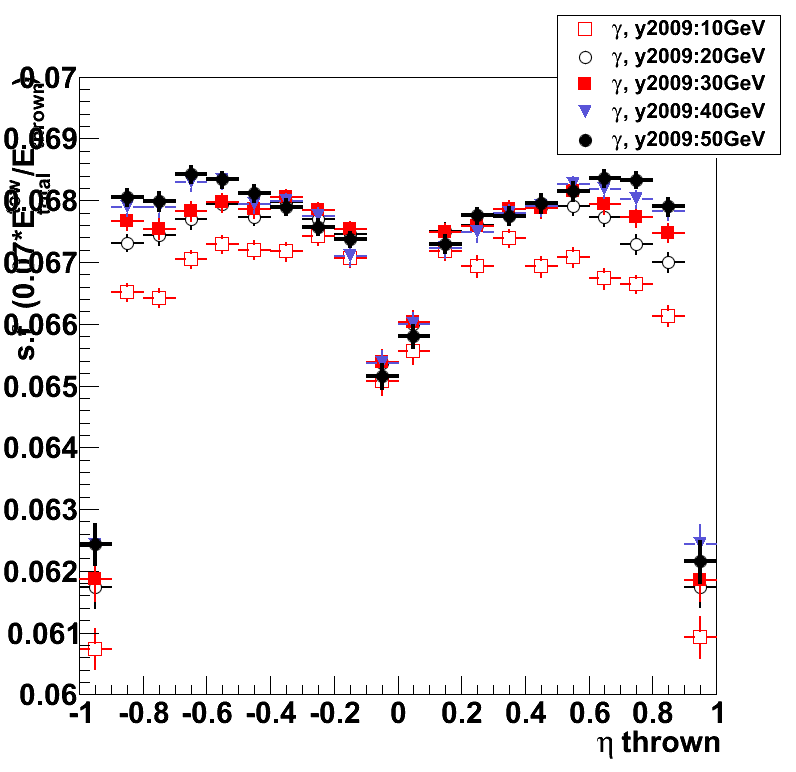

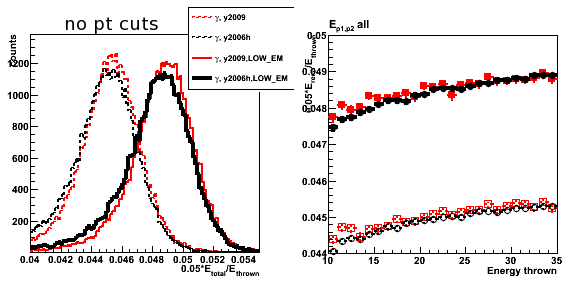

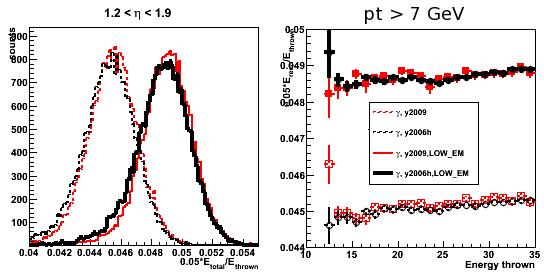

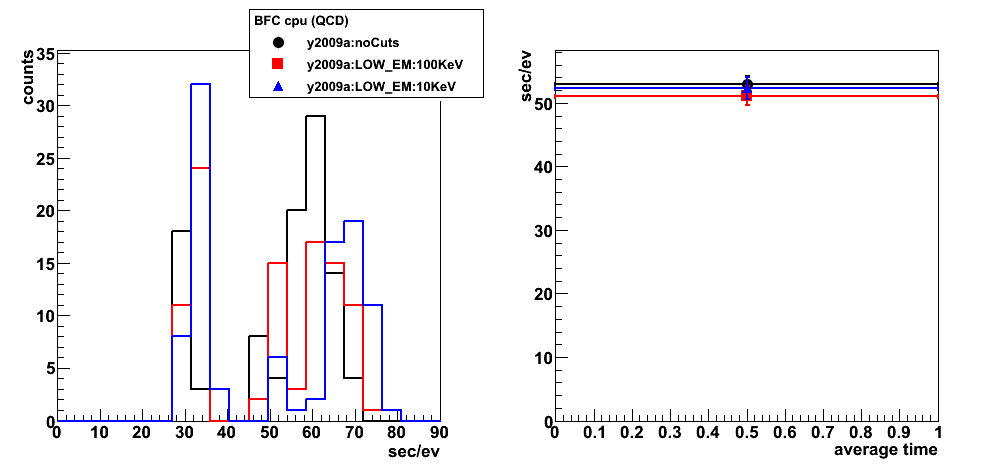

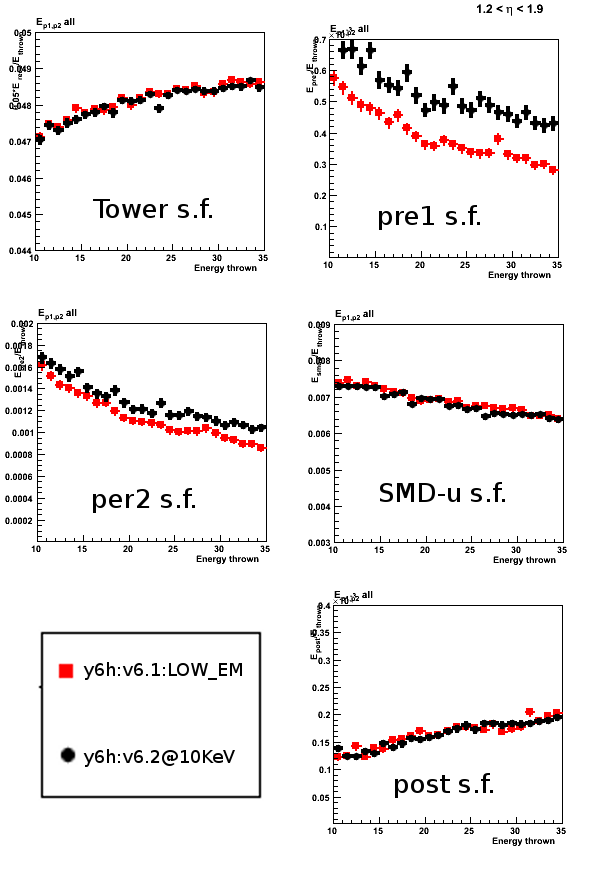

2009.09.11 Test of corrected EEMC geometry: LOW_EM cuts

Test of corrected EEMC geometry: SVT and LOW_EM cuts

Monte-Carlo setup:

- One particle per event (only photons in this post)

- Full STAR 2006 geometry (with/without SVT, LOW_EM cuts)

In Kumac file: detp geom y2006g; gexec $STAR_LIB/geometry.so (vary SVTT_OFF, LOW_EM)

LOW_EM cut definition is given at the end of this page - Throw particles flat in eta (1.2, 1.9), phi (0, 2pi), and pt (6-10 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy

(this post: no EEMC SlowSimulator) - Vertex z=0

- ~50K/per iteration

- Non-zero energy: 3 sigma above pedestal

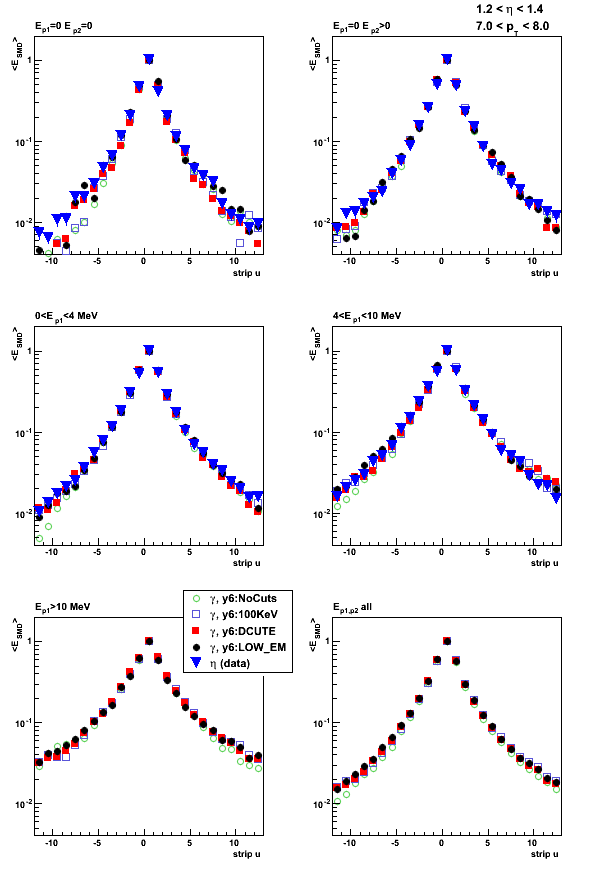

Color coding:

- SVT, LOW_EM marked in legend as LowEM (single photon MC)

- STV, no-LOW_EM marked in legend as default (single photon MC)

- no-SVT, no-LOW_EM marked in legend as no-SVT (single photon MC)

- photon-jet candidates [pp2006] (used data points from this post)

- photons from eta-meson [pp2006]

Pre-shower bins:

- Ep1 = Ep2 = 0 (no energy in both EEMC pre-shower layers)

- Ep1 = 0, Ep2 > 0

- 0 < Ep1 < 4 MeV

- 4 < Ep1 < 10 MeV

- Ep1 > 10 MeV

- All pre-shower bins combined

Note: Ep1/Ep2 is the energy deposited in the 1st/2nd EEMC pre-shower layer.

For a single photon MC it is a sum over

all pre-shower tiles in the EEMC with energy of 3 sigma above pedestal.

For eta-meson/gamma-jet candidates from pp2006 data the sum is over 3x3 tower patch

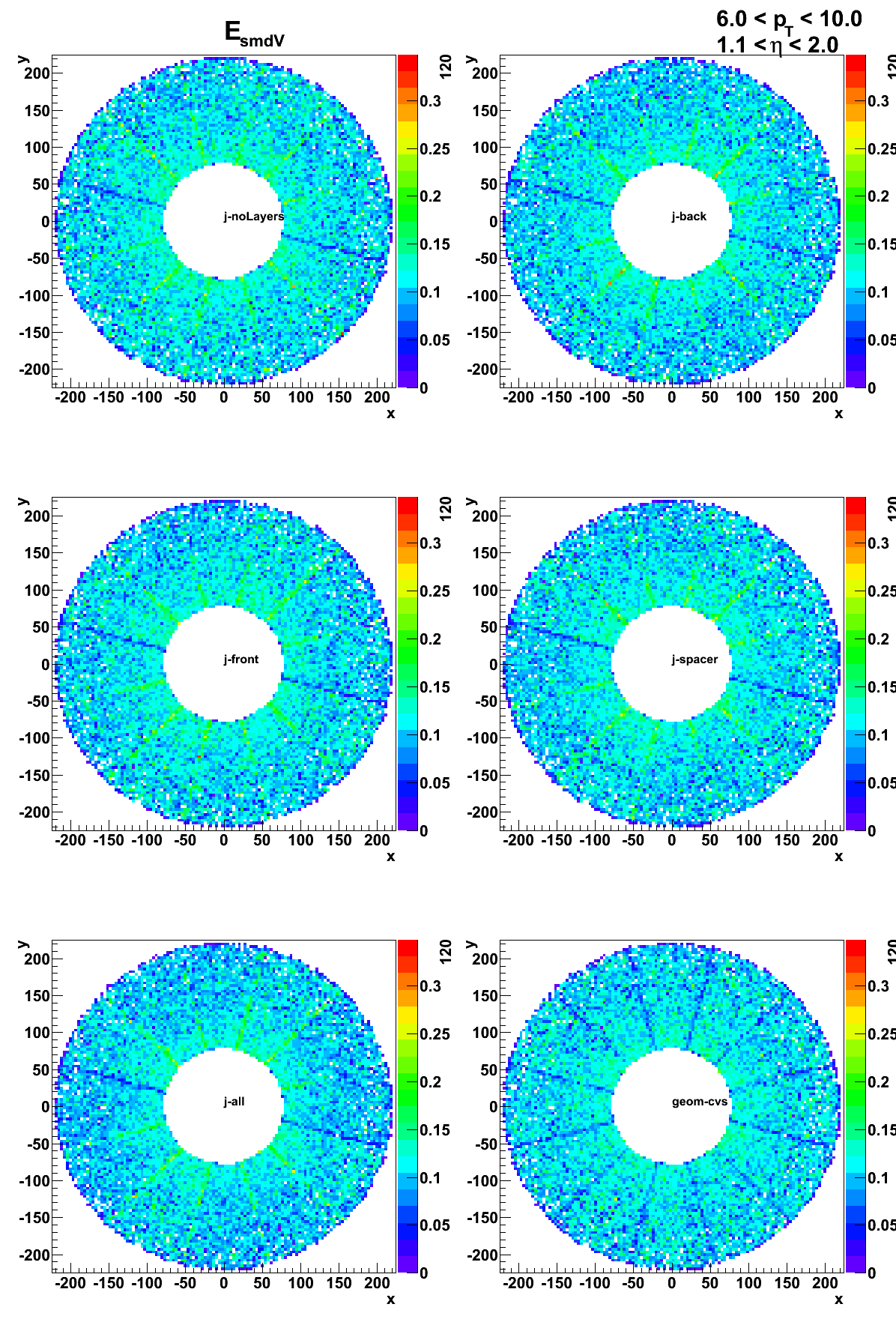

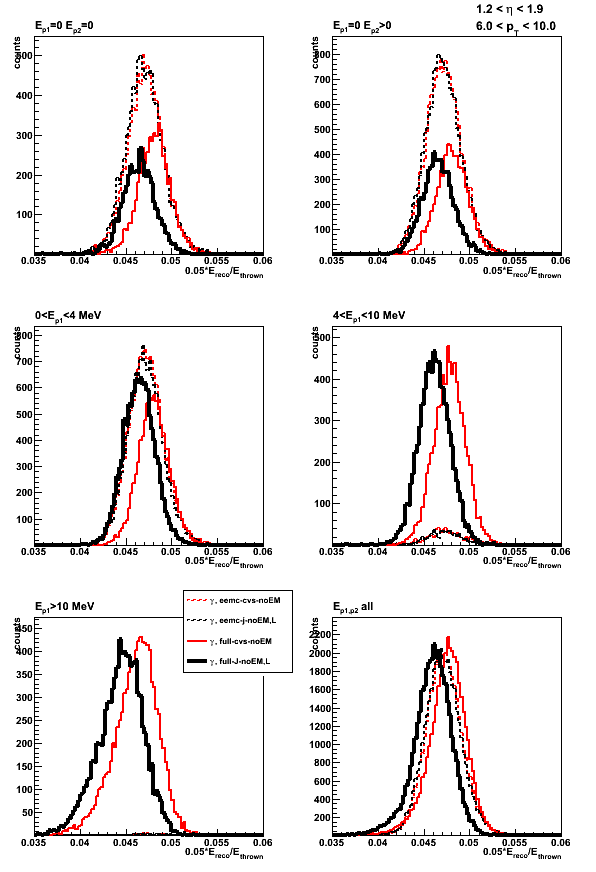

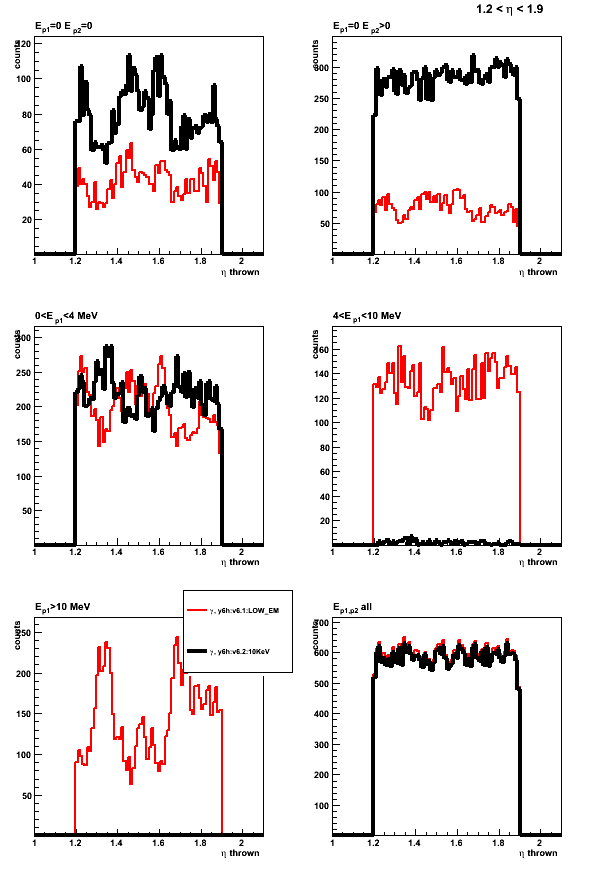

Shower shapes

Single particle kinematic cuts: pt=7-8GeV, eta=1.2-1.4

Eta-meson shower shapes (blue) taken from Fig. 1 from here of this post

All shapes are normalized to 1 at peak (central strip)

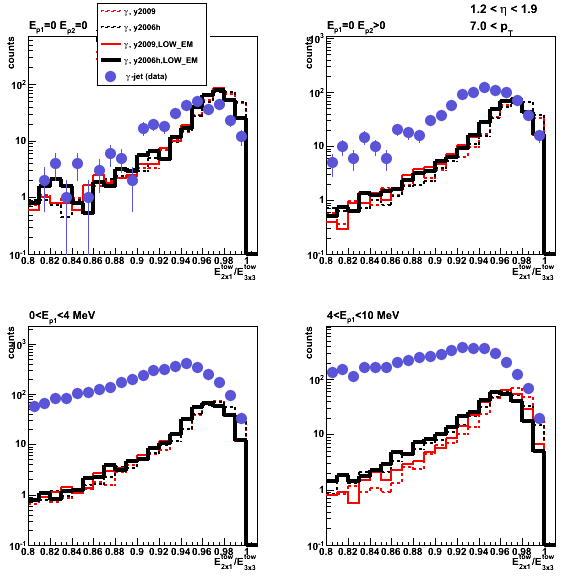

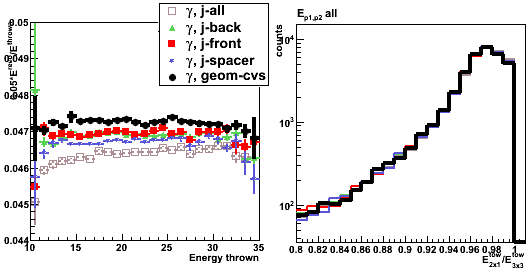

Figure 1: Shower shape sorted by pre-shower conditions.

Figure 2: Shower shape ratio. All shapes in Fig. 1 are divided by single photon shape

for "SVT+LOW_EM" configuration (black circles in Fig. 1)

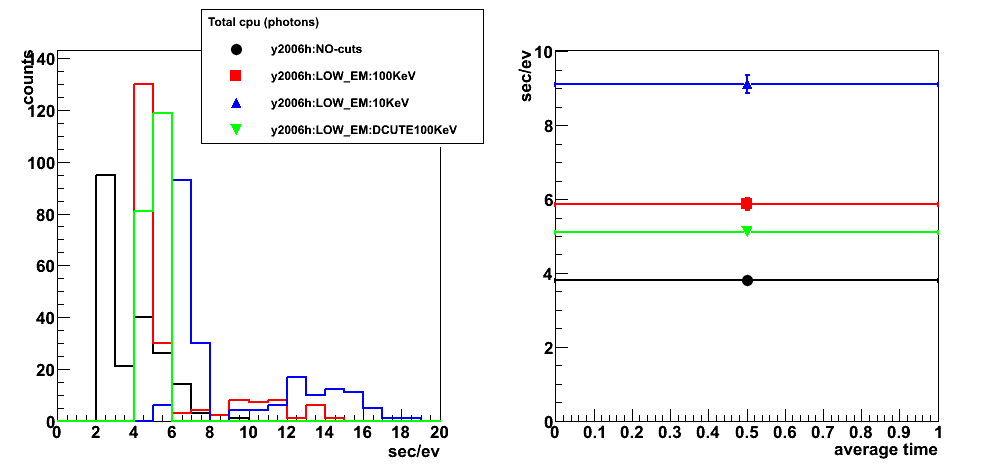

Sampling fraction

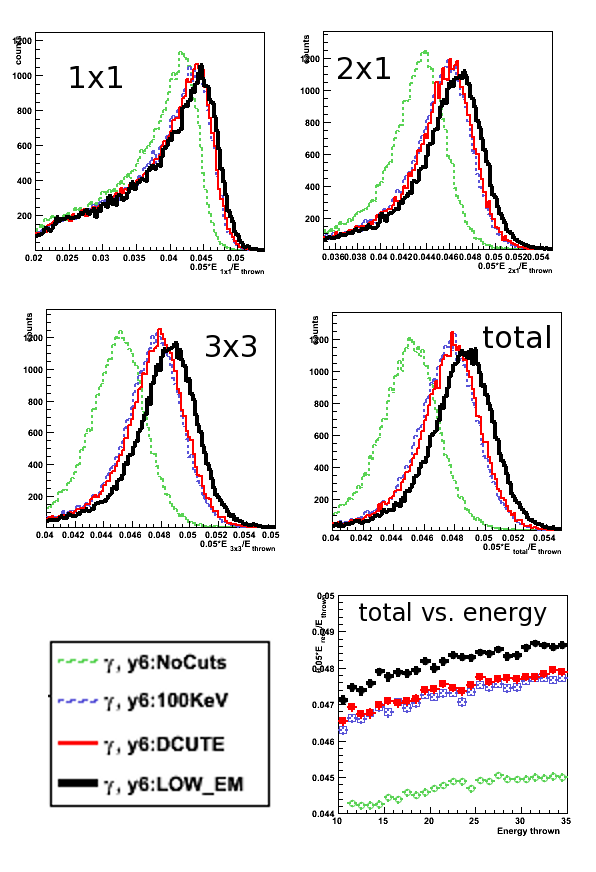

Figure 3: Sampling fraction (0.05 * E_reco/ E_thrown)

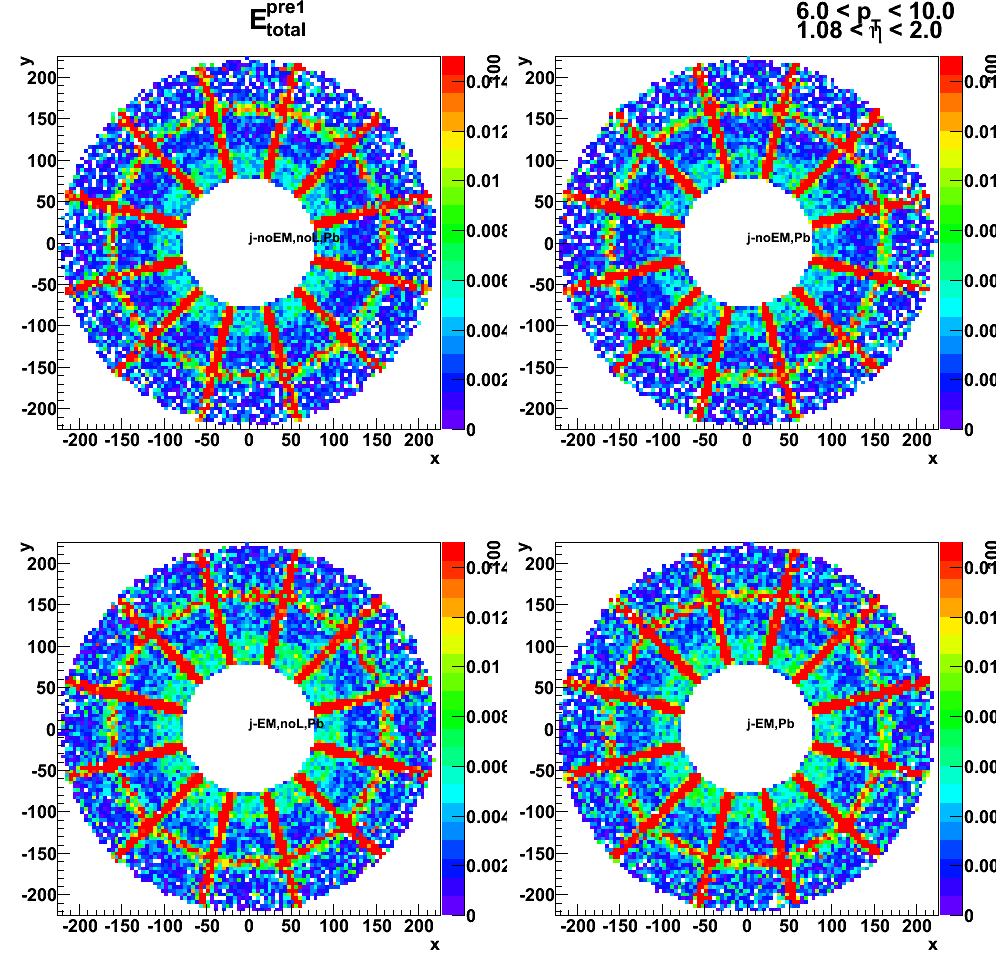

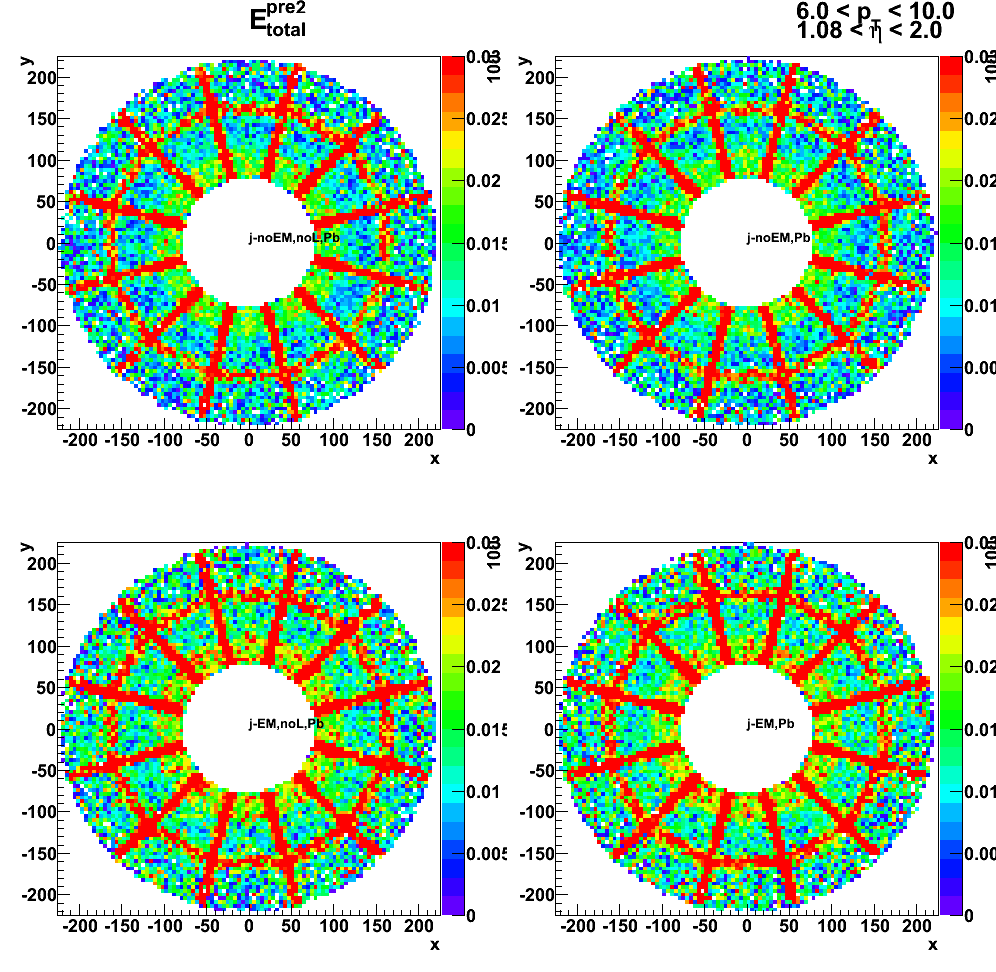

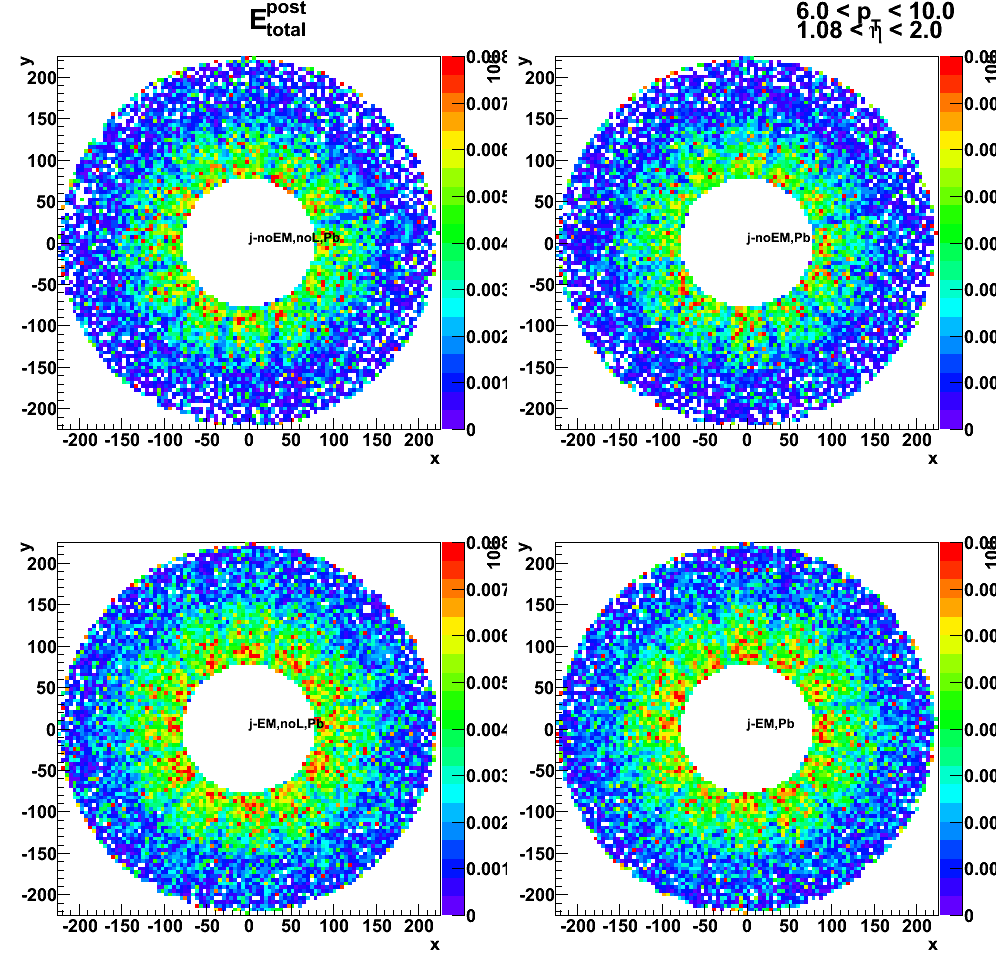

Pre/post-shower energy and migration

Figure 4: Pre-shower1 energy (all tiles)

Figure 5: Pre-shower2 energy (all tiles)

Figure 6: Post-shower energy (all tiles)

Figure 7: Pre-shower bin photon migration

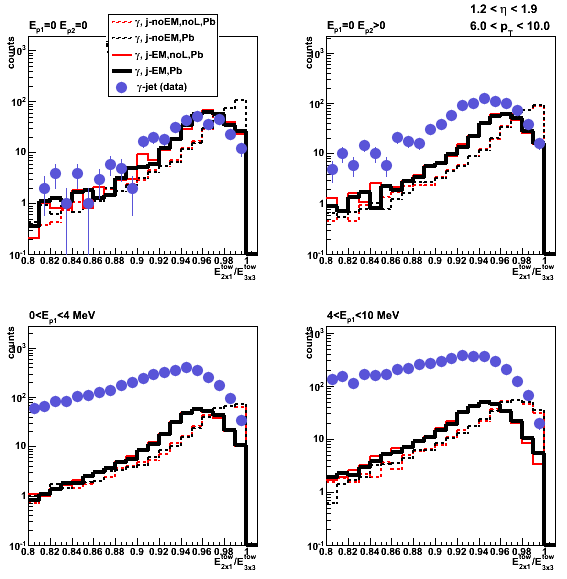

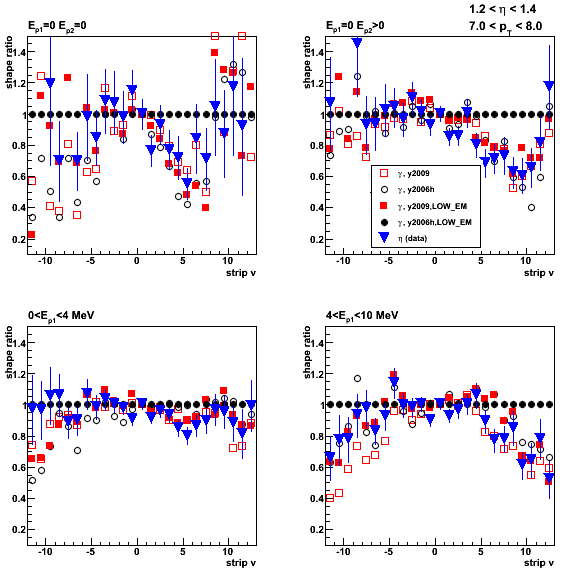

Tower energy profile

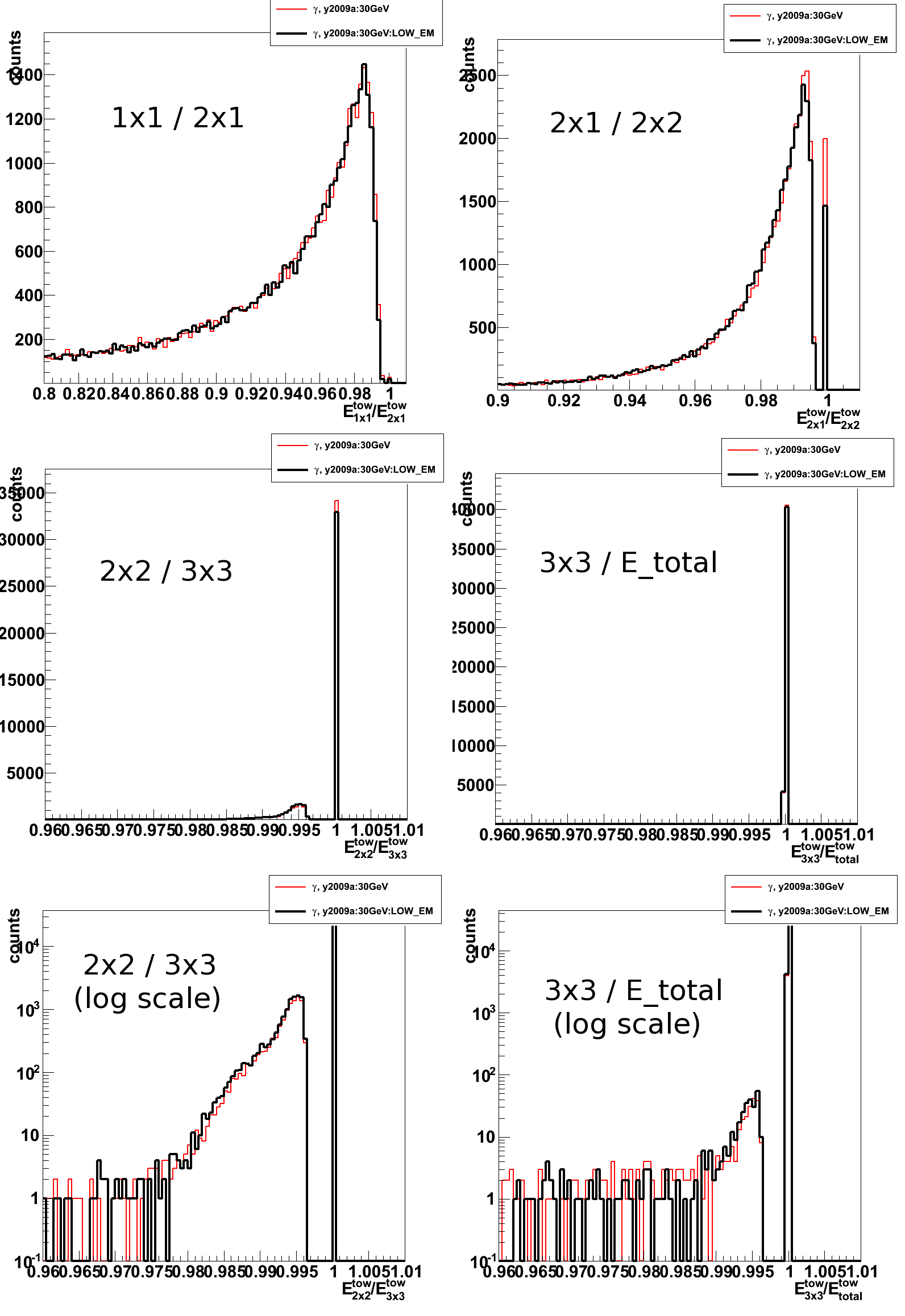

Figure 8a: Energy ratio in 2x1 to 3x3 cluster

For the first 4 pre-shower bins total yield in MC is normalized to that of the data

Blue circles indicate photon-jet candidates [pp2006] (points from this post)

Same data on a linear scale

Figure 8b: Energy ratio in 2x1 to 3x3 cluster: 7 < pt < 8 and 1.2 < eta < 1.4

Figure 8c: Energy ratio in 2x1 to 3x3 cluster: 7 < pt < 8 and 1.6 < eta < 1.8

Figure 9: Average energy ratio in 2x1 to 3x3 cluster vs. thrown energy

Figure 10: Average energy ratio in 2x1 to 3x3 cluster vs. thrown energy

LOW_EM cut definition

LOW_EM option for the STAR geometry (Low cuts on Electro-Magnetic processes)

is equivalent to the following set of GEANT cuts:

- CUTGAM=0.00001

- CUTELE=0.00001

- BCUTE =0.00001

- BCUTM =0.00001

- DCUTE =0.00001

- DCUTM =0.00001

All these values are for kinetic energy in GeV.

Cut meaning and GEANT default values:

- CUTGAM threshold for gamma transport (0.001);

- CUTELE threshold for electron and positron transport (0.001);

- BCUTE threshold for photons produced by electron bremsstrahlung (-1,);

- BCUTM threshold for photons produced by muon bremsstrahlung (-1);

- DCUTE threshold for electrons produced by electron delta-rays (-1);

- DCUTM threshold for electrons produced by muon or hadron delta-rays (-1);

Some details can be found at this link and in the GEANT manual

10 Oct

October 2009 posts

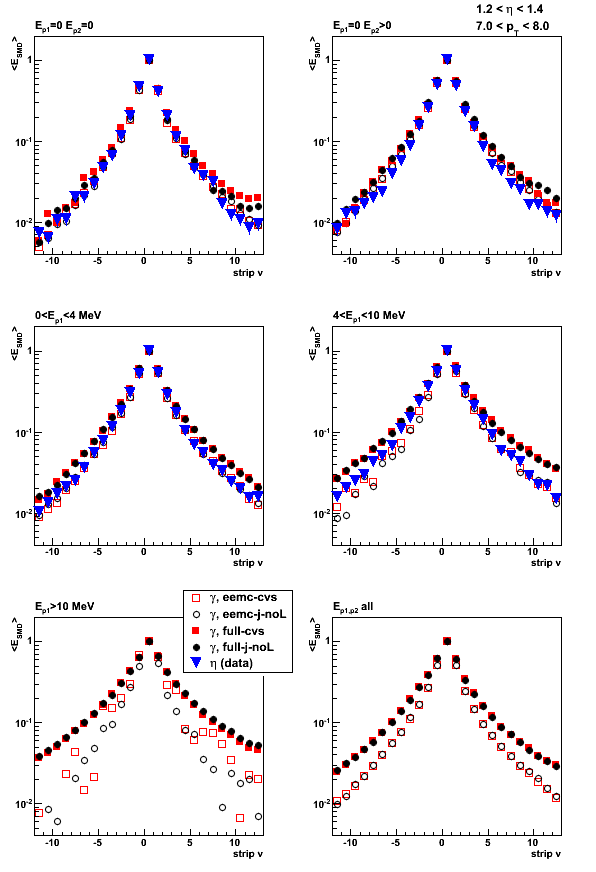

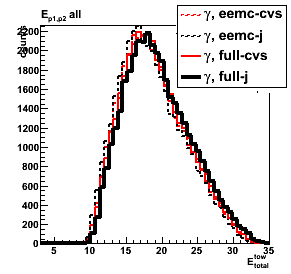

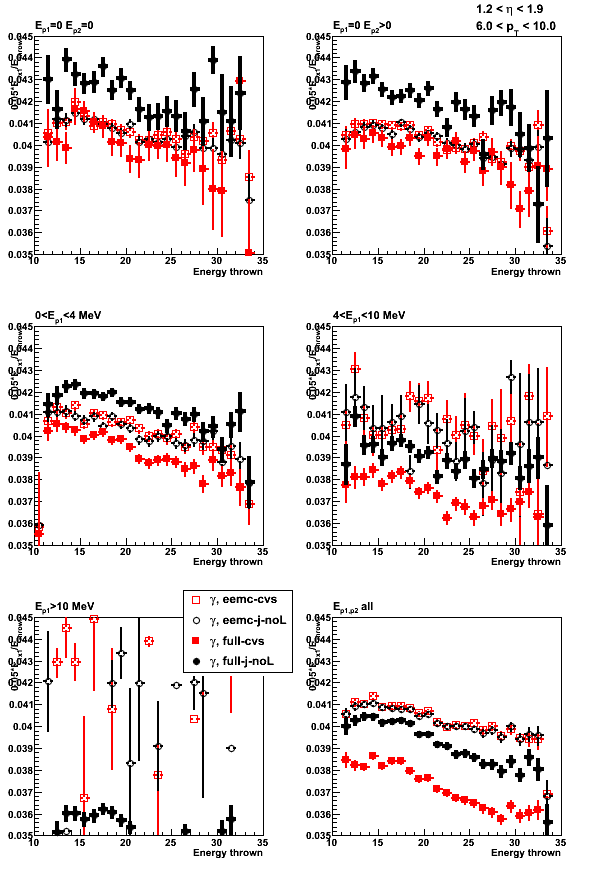

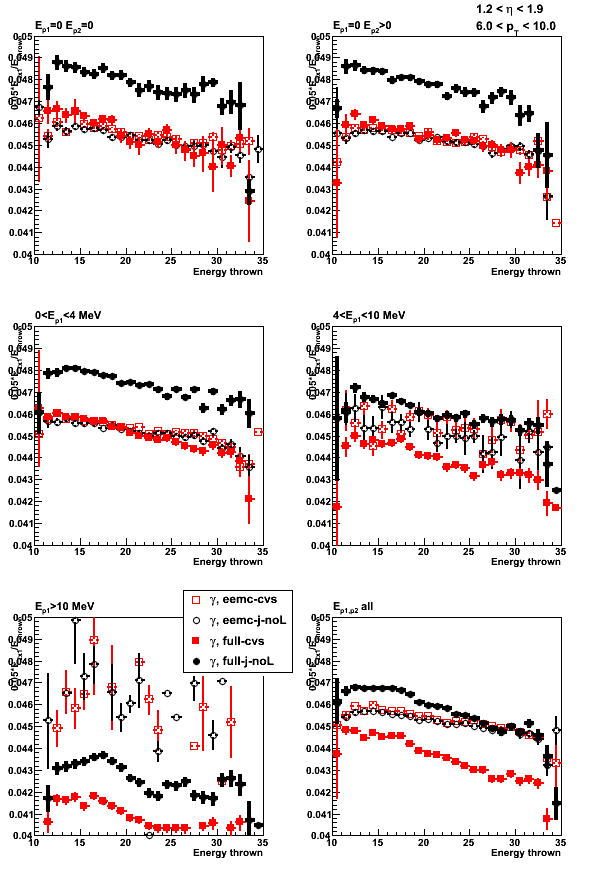

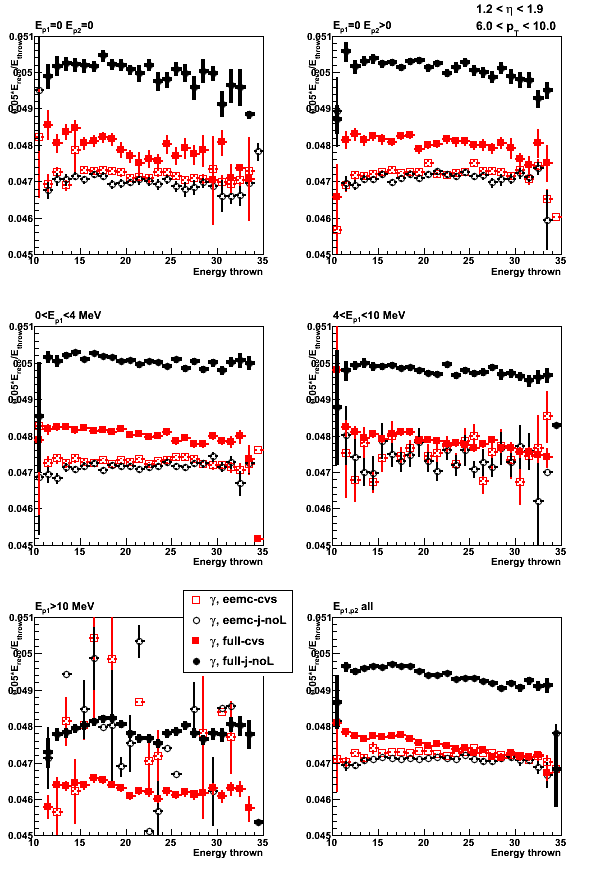

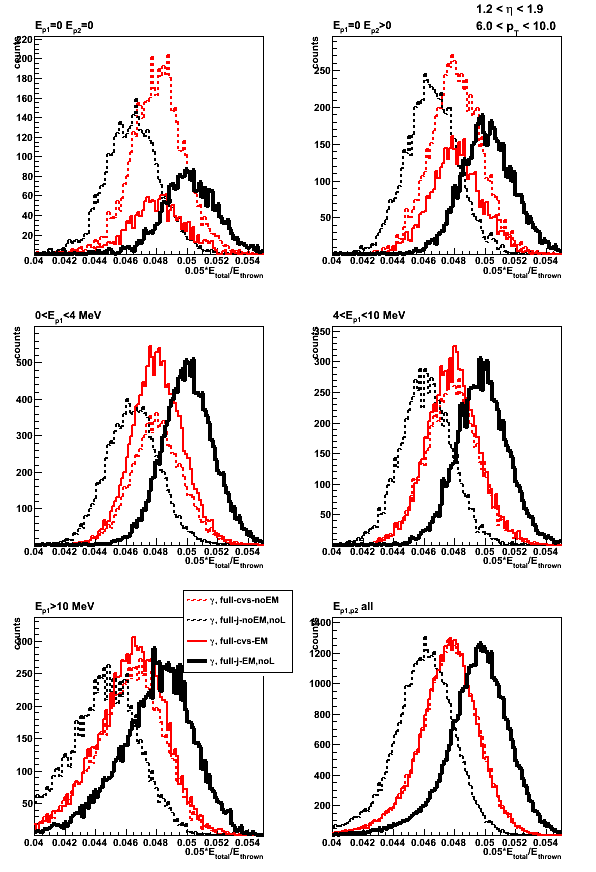

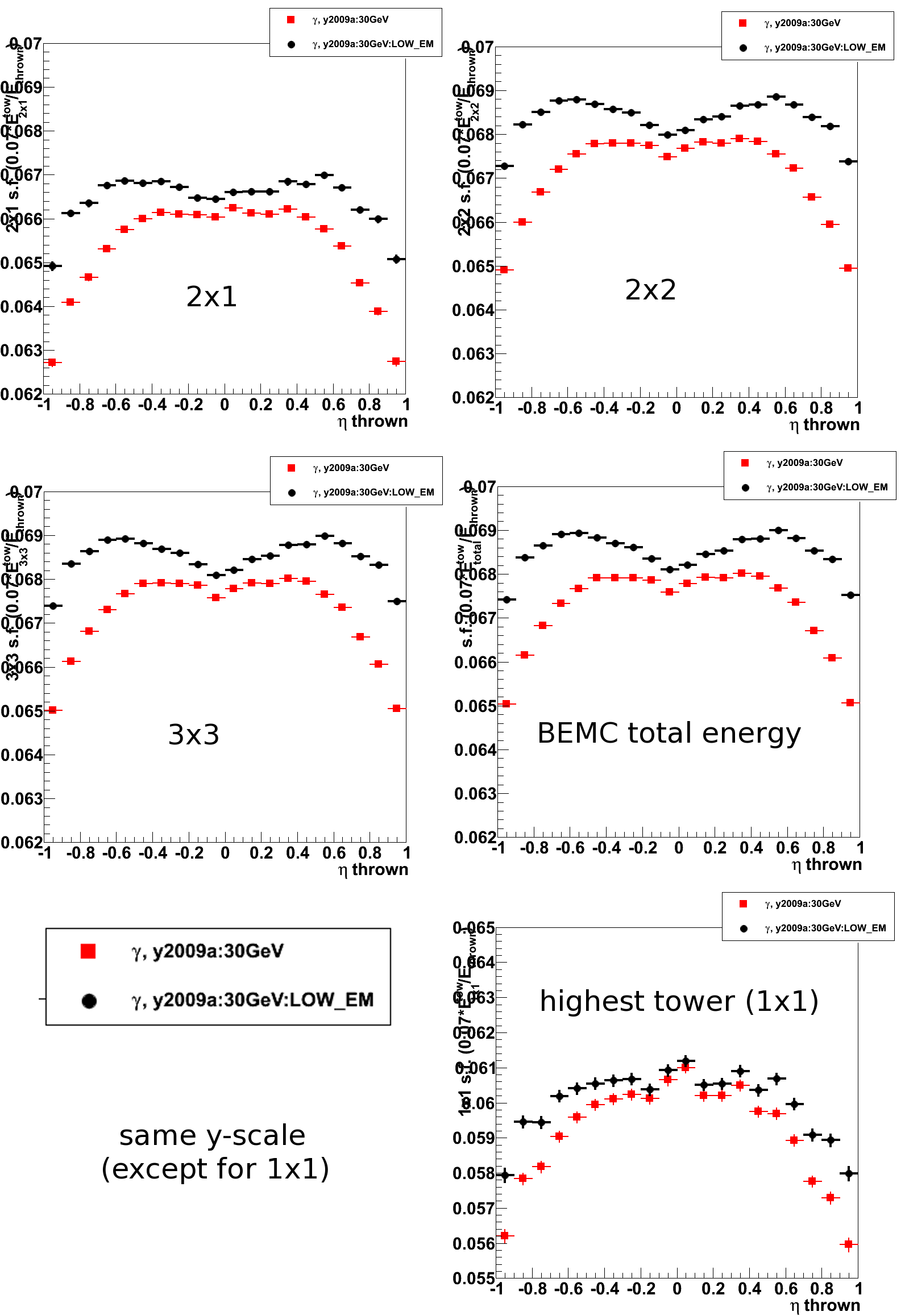

2009.10.02 Jason vs. CVS EEMC geometry: sampling fraction and shower shapes

Tests with Jason geometry file (ecalgeo.g23)

Monte-Carlo setup:

- One photon per event

- EEMC only geometry with LOW_EM option

- Throw particles flat in eta (1.08, 2.0), phi (0, 2pi), and pt (6-10 GeV)

- Using A2Emaker to get reconstructed Tower/SMD energy

(no EEMC SlowSimulator in chain) - Vertex z=0

- ~50K/per particle type

- Non-zero energy: 3 sigma above pedestal

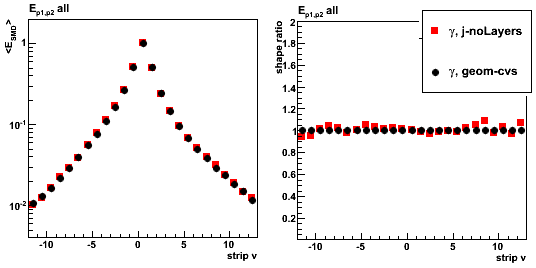

Color coding:

- Photon with Jason geometry (single particle MC)

- Photon with CVS (cAir fix) geometry (single particle MC)

- Eta-meson [pp2006 data] (single photons from eta-meson decay)

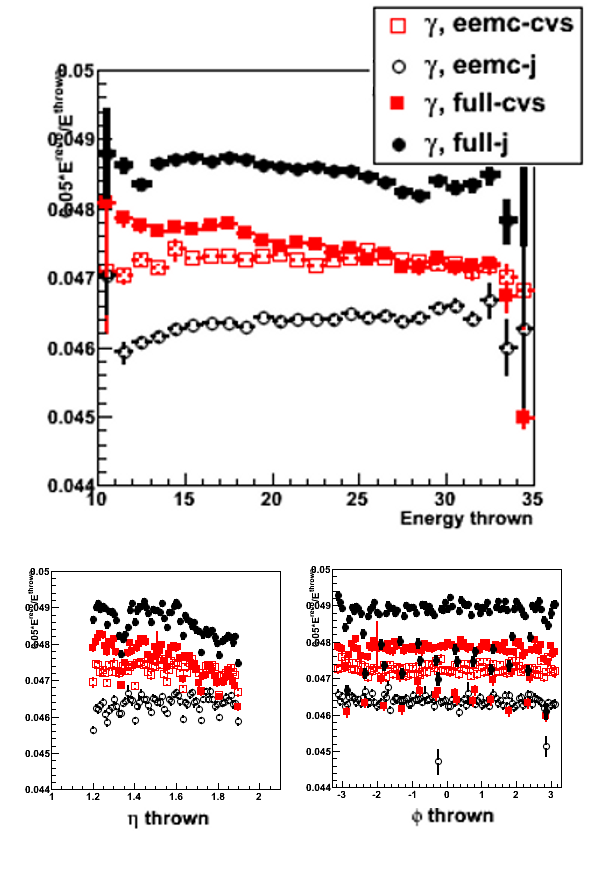

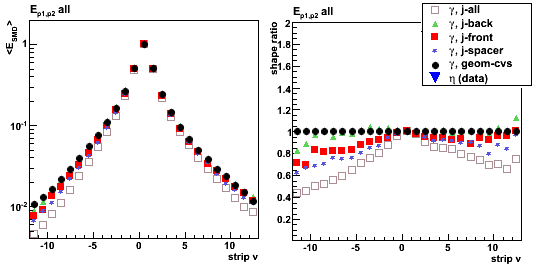

Sampling fraction

Figure 1: Sampling fraction vs. thrown energy (upper plot)

and vs. azimuthal angle (lower left) and rapidity (lower right)

Shower shapes

Single particle kinematic cuts: pt=7-8GeV, eta=1.2-1.4

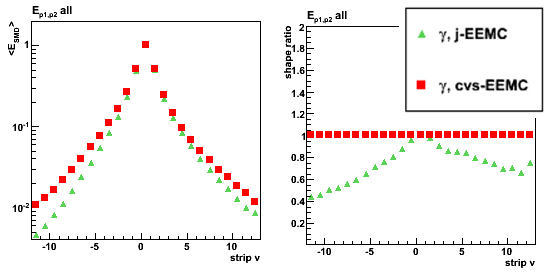

Eta-meson shower shapes (blue) taken from Fig. 1 from here of this post

All shapes are normalized to 1 at peak (central strip)

Shower shapes sorted by pre-shower energy

Pre-shower bins:

- Ep1 = 0, Ep2 = 0 (no energy in both EEMC pre-shower layers)

- Ep1 = 0, Ep2 > 0

- 0 < Ep1 < 4 MeV

- 4 < Ep1 < 10 MeV

- Ep1 > 10 MeV

- All pre-shower bins combined

Ep1/Ep2 is the energy deposited in the 1st/2nd EEMC pre-shower layer.

For a single particle MC it is a sum over

all pre-shower tiles in the EEMC with energy of 3 sigma above pedestal.

For eta-meson from pp2006 data the sum is over 3x3 tower patch

2009.10.05 Fix to the Jason geometry file

Why volume numbers has changed in Jason geometry file?

The number of nested volumes (nv),

is the total number of parent volumes for the sensitive volume

(sensitive volume is indicated by the HITS in the tree structure below).

For the Jason and CVS files this nv number seems to be the same

(see block tree structures below).

Then why volume ids id in g2t tables has changed?

The answer I found (which seems trivial to me know)

is that in the original (CVS) file ECAL

block has been instantiated (positioned) twice.

The second appearance is the prototype (East) version of the Endcap

(Original ecalgeo.g from CVS)

if (emcg_OnOff==1 | emcg_OnOff==3) then Position ECAL in CAVE z=+center endif if (emcg_OnOff==2 | emcg_OnOff==3) then Position ECAL in CAVE z=-center ThetaZ=180 endif

In Jason version the second appearance has been removed

(what seems natural and it should not have any effect)

(ecalgeo.g Jason edits, g23):

IF (emcg_OnOff>0) THEN Create ECAL ..... IF (emcg_OnOff==2 ) THEN Prin1 ('East Endcap has been removed from the geometry' ) ENDIF EndIF! emcg_OnOff

Unfortunately, this affects the way GEANT counts nested volumes

(effectively the total number was reduced by 1, from 8 to 7)

and this is the reason why the volume numbering scheme

in g2t tables has been affected.

I propose to put back these East Endcap line back,

since in this case it will not require any additional

changes to the EEMC decoder and g2t tables.

Block tree of the geometry file

blue - added volumes in Jason file

red - G10 volume removed in Jason file

HITS - sensitive volumes

---- Jason file ----

ECAL

EAGA

|EMSS

| -EFLP

| |ECVO

| | |EMOD

| | | |ESEC

| | | | |ERAD

| | | | | -ELED

| | | | |EMGT

| | | | | |EPER

| | | | | | |ETAR

| | | | | | | -EALP

| | | | | | | -ESCI -> HITS

| |ESHM

| | |ESPL

| | | |EXSG

| | | | -EXPS

| | | | -EHMS -> HITS

| | | | -EBLS

| | | | -EFLS

| | |ERSM

| -ESSP

| -ERCM

| -EPSB

|ECGH

| -ECHC

---- CVS file ----

ECAL

EAGA

|EMSS

| -EFLP

| |ECVO

| | |EMOD

| | | |ESEC

| | | | |ERAD

| | | | | -ELED

| | | | |EMGT

| | | | | |EPER

| | | | | | |ETAR

| | | | | | | -EALP

| | | | | | | -ESCI -> HITS

| |ESHM

| | |ESPL

| | | |EXSG

| | | | -EHMS -> HITS

| | | -EXGT

| | -ERSM

| -ESSP

| -ERCM

| -EPSB

|ECGH

| -ECHC

Block definitions

Jason geometry file

Create ECAL Block ECAL is one EMC EndCap wheel Create and Position EAGA AlphaZ=halfi EndBlock Block EAGA IS HALF OF WHEEL AIR VOLUME FORTHE ENDCAP MODULE Create AND Position EMSS konly='MANY' Create AND Position ECGH alphaz=90 kOnly='ONLY' EndBlock Block EMSS is the steel support of the endcap module Create AND Position EFLP z=zslice-center+zwidth/2 Create AND Position ECVO z=zslice-center+zwidth/2 Create AND Position ESHM z=zslice-center+zwidth/2 kOnly='MANY' Create AND Position ECVO z=zslice-center+zwidth/2 Create AND Position ESSP z=zslice-center+zwidth/2 Create ERCM Create EPSB EndBlock Block ECVO is one of endcap volume with megatiles and radiators Create AND Position EMOD alphaz=d3 ncopy=i_sector EndBlock Block ESHM is the shower maxsection Create and Position ESPL z=currentk Only='MANY' Create ERSM EndBlock Block ECGH is air gap between endcap half wheels Create ECHC EndBlock Block ECHC is steel endcap half cover EndBlock Block ESSP is stainless steelback plate EndBlock Block EPSB IS A PROJECTILE STAINLESS STEEL BAR EndBlock Block ERCM is stainless steel tie rod in calorimeter sections EndBlock Block ERSM is stainless steel tie rod in shower max EndBlock Block EMOD (fsect,lsect) IS ONE MODULEOF THE EM ENDCAP Create AND Position ESEC z=section-curr+secwid/2 EndBlock Block ESEC is a single em section Create AND Position ERAD z=length+(cell)/2+esec_deltaz Create AND Position EMGT z=length+(gap+cell)/2+esec_deltaz Create AND Position ERAD z=length+cell/2+esec_deltaz EndBlock Block EMGT is a 30 degree megatile Create AND Position EPER alphaz=myPhi EndBlock Block EPER is a 5 degree slice of a 30 degree megatile (subsector) Create and Position ETAR x=(rbot+rtop)/2ort=yzx EndBlock Block ETAR is a single calorimeter cell, containing scintillator, fiber router, etc... Create AND Position EALP y=(-megatile+emcs_alincell)/2 Create AND Position ESCI y=(-megatile+g10)/2+emcs_alincell _ EndBlock Block ESCI is the active scintillator (polystyrene) layer EndBlock Block ERAD is the lead radiator with stainless steel cladding Create AND Position ELED EndBlock Block ELED is a lead absorber plate EndBlock Block EFLP is the aluminum (aluminium) front plate of the endcap EndBlock Block EALP is the thin aluminium plate in calorimeter cell EndBlock Block ESPL is the logical volume containing an SMD plane Create and Position EXSG alphaz=d3 ncopy=isec kOnly='MANY' Create and Position EXSG alphaz=d3 ort=x-y-z ncopy=isec kOnly='MANY' Create and Position EXSG alphaz=d3 ncopy=isec kOnly='MANY' Create and Position EXSG alphaz=d3 ort=x-y-z ncopy=isec kOnly='MANY' Create and Position EXSG alphaz=d3 ncopy=isec kOnly='MANY' EndBlock Block EXSG Is another logical volume... this one acutally creates the planes Create and Position EXPS kONLY='MANY' Create and Position EHMS x=xc y=yc alphaz=-45 kOnly='ONLY' Create and Position EBLS x=xc y=yc z=(+esmd_apex/2+esmd_back_layer/2) alphaz=-45 kOnly='ONLY' Create and Position EHMS x=xc y=yc alphaz=-45 ort=x-y-z kOnly='ONLY' Create and Position EFLS x=xc y=yc z=(-esmd_apex/2-esmd_front_layer/2) alphaz=-45 ort=x-y-z kOnly='ONLY' EndBlock Block EHMS defines the triangular SMD strips Endblock! EHMS Block EFLS is the layer of material on the front of the SMD planes EndBlock! EFLS Block EBLS is the layer of material on the back of the SMD planes EndBlock! EFLS Block EXPS is the plastic spacer in the shower maximum section EndBlock

CVS geometry file

Create ECAL Block ECAL is one EMC EndCap wheel Create and Position EAGA AlphaZ=halfi EndBlock Block EAGA is half of wheel air volume forthe EndCap module Create and Position EMSS konly='MANY' Create and Position ECGH AlphaZ=90 konly='ONLY' EndBlock Block EMSS is steel support of the EndCap module Create and Position EFLP z=zslice-center+slcwid/2 Create and Position ECVO z=zslice-center+slcwid/2 Create and Position ESHM z=zslice-center+slcwid/2 Create and Position ECVO z=zslice-center+slcwid/2 Create and Position ESSP z=zslice-center+slcwid/2 Create ERCM Create EPSB EndBlock Block ECVO is one of EndCap Volume with megatiles and radiators Create and Position EMOD AlphaZ=d3 Ncopy=J_section EndBlock Block ESHM is the SHower Maxsection Create and Position ESPL z=current Create ERSM Endblock Block ECGH is air Gap between endcap Half wheels Create ECHC EndBlock Block ECHC is steel EndCap Half Cover EndBlock Block ESSP is Stainless Steelback Plate endblock Block EPSB is Projectile Stainless steel Bar endblock Block ERCM is stainless steel tie Rod in CaloriMeter sections endblock Block ERSM is stainless steel tie Rod in Shower Max endblock Block EMOD is one moduleof the EM EndCap Create and Position ESEC z=section-curr+secwid/2 endblock Block ESEC is a single EM section Create and Position ERAD z=len + (cell)/2 Create and Position EMGT z=len +(gap+cell)/2 Create and Position ERAD z=len + cell/2 Endblock Block EMGT is a megatile EM section Create and Position EPER AlphaZ=(emcs_Nslices/2-isec+0.5)*dphi Endblock Block EPER is a EM subsection period (super layer) Create and Position ETAR x=(RBot+RTop)/2ORT=YZX EndBlock Block ETAR is one CELL of scintillator, fiber and plastic Create and Position EALP y=(-mgt+emcs_AlinCell)/2 Create and Position ESCI y=(-mgt+G10)/2+emcs_AlinCell _ EndBlock Block ESCI is the active scintillator (polystyren) layer endblock Block ERAD is radiator Create and PositionELED endblock Block ELED is lead absorber Plate endblock Block EFLP is First Aluminium plate endblock Block EALP is ALuminiumPlate in calorimeter cell endblock Block ESPL is one of the Shower maxPLanes Create and position EXSG AlphaZ=d3Ncopy=isec Create and position EXSG AlphaZ=d3Ncopy=isec Create and position EXGT z=msecwd AlphaZ=d3 Create and position EXSG AlphaZ=d3 ORT=X-Y-Z Ncopy=isec Create and position EXGT z=-msecwd AlphaZ=d3 Create and position EXSG AlphaZ=d3Ncopy=isec Create and position EXGT z=msecwd AlphaZ=d3 Create and position EXSG AlphaZ=d3 ORT=X-Y-Z Ncopy=isec Create and position EXGT z=-msecwd AlphaZ=d3 Endblock Block EXSG is the Shower maxGap for scintillator strips Create EHMS endblock Block EHMS is sHower Max Strip Endblock Block EXGT is the G10 layer in the Shower Max EndBlock

Original (ecalgeo.g) file from CVS

Original (ecalgeo.g) file from CVS